Content .. 1175 1176 1177 1178 ..

Nissan Rogue. Manual - part 1177

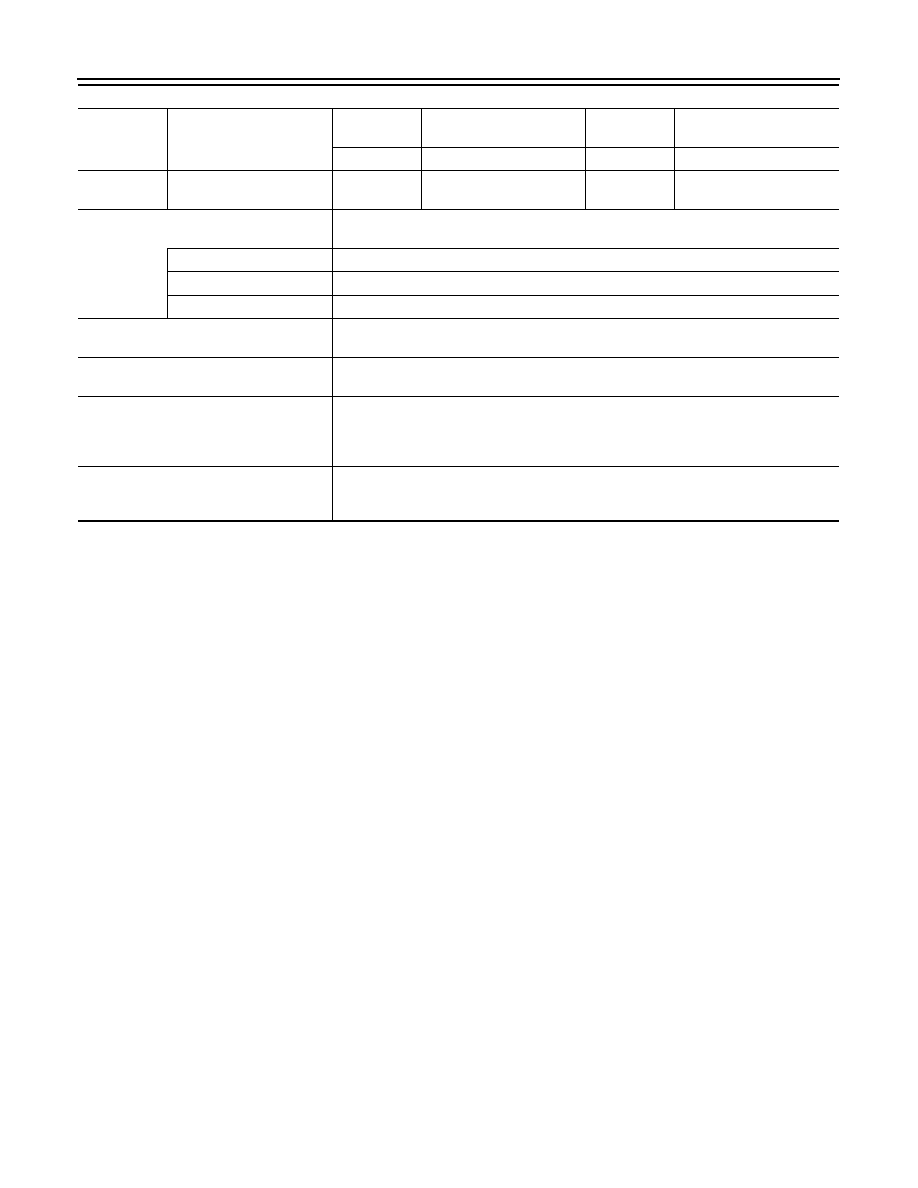

TM-80

< BASIC INSPECTION >

[CVT: RE0F10D]

DIAGNOSIS AND REPAIR WORK FLOW

Climate con-

ditions

Irrelevant

Weather

Clear

Cloud

Rain

Snow

Others

)

Temperature

Hot

Warm

Cool

Cold

Temperature (Approx.

°C/°F)

Relative humidity

High

Moderate

Low

Transaxle condition

In cold-start

During warm-up (approx.

°C/°F)

After warm-up

Engine speed:

rpm

Road conditions

Urban area

Suburb area

Highway

Mountainous road (uphill or downhill)

Operating condition, etc.

Irrelevant

When engine starts

During idling

During driving

During acceleration

At constant speed driving

During deceleration

During cornering (RH curve or LH curve)

Other conditions

Question sheet

Customer's

name

MR/MS

Registration

number

Initial year

registration

Year

Month

day

Vehicle type

Chassis No.

Storage date

Year

Month

day

Engine

Mileage

km/mile