Nissan Maxima. Manual - part 889

PCS-36

< BASIC INSPECTION >

[POWER DISTRIBUTION SYSTEM]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

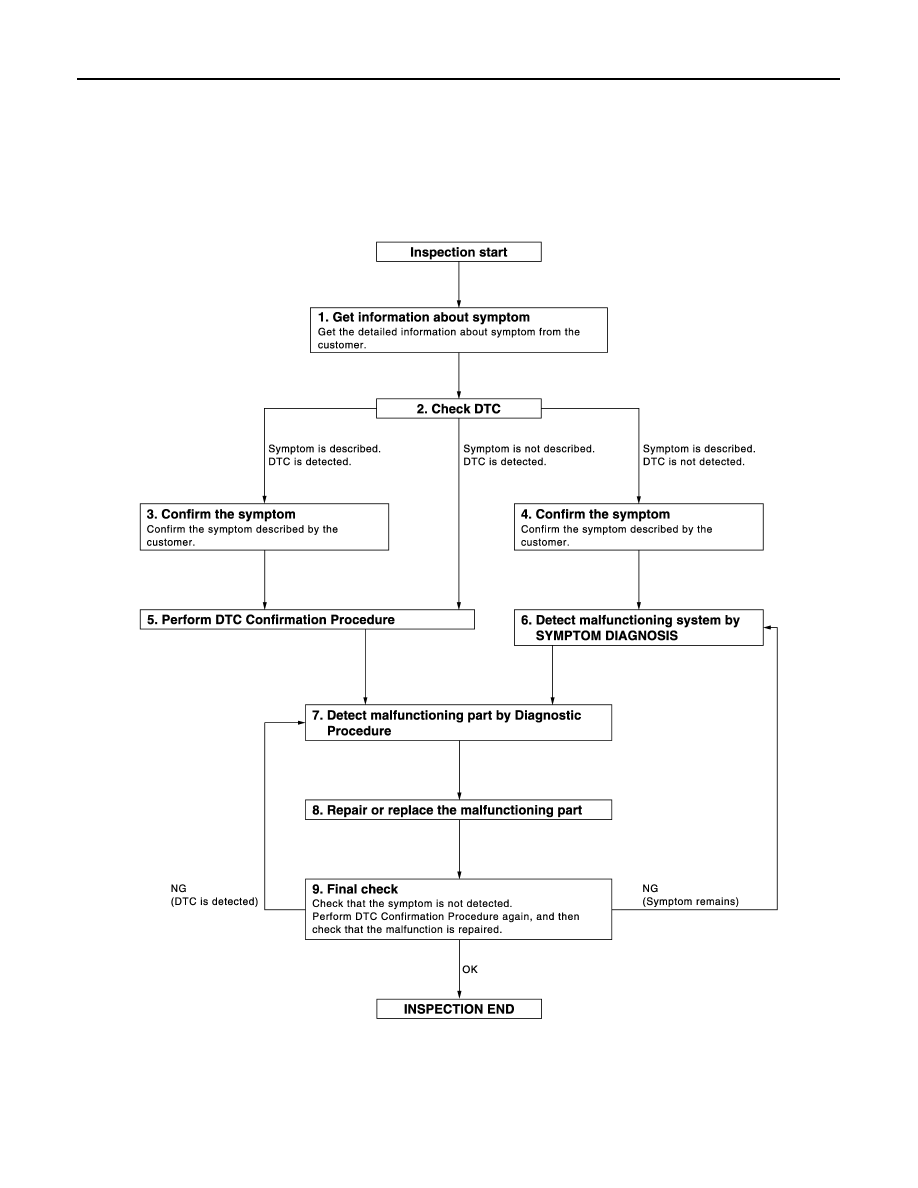

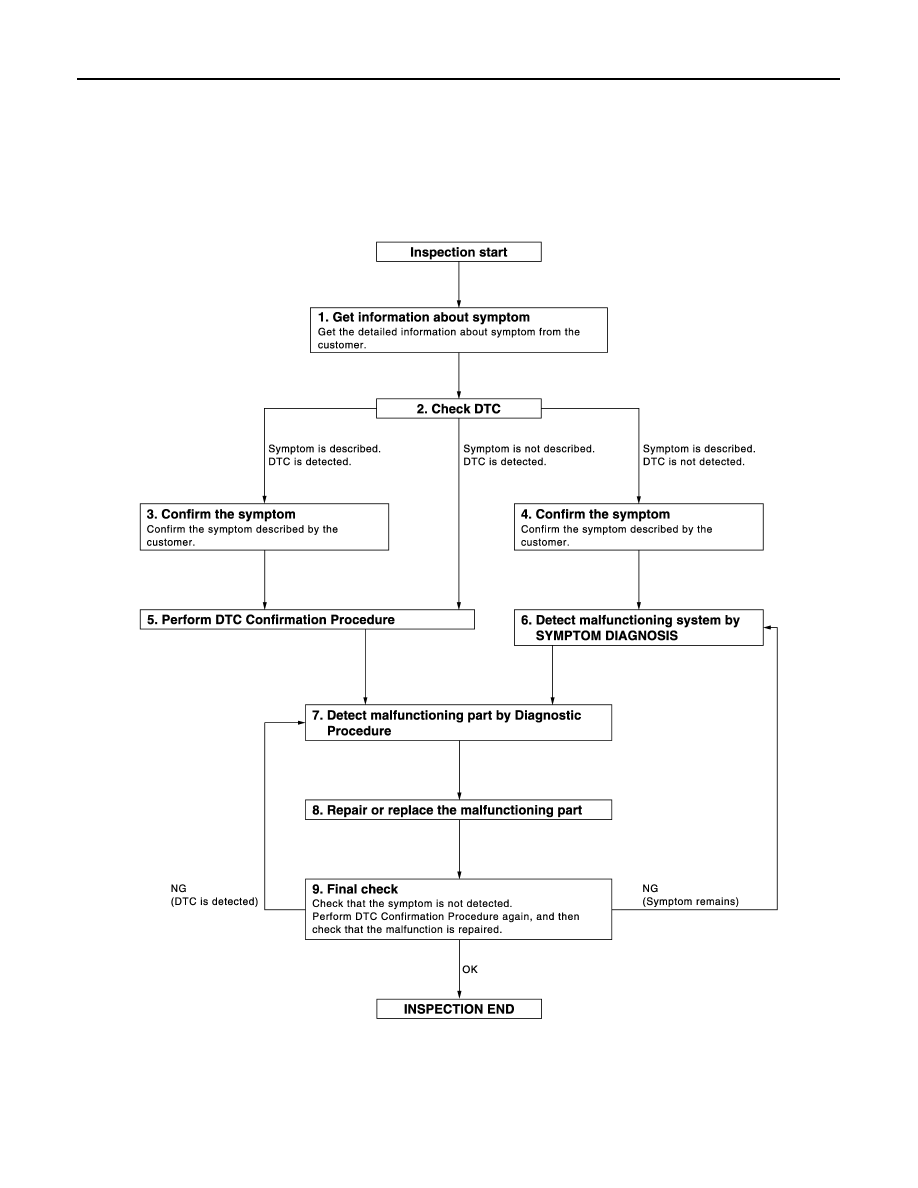

Work Flow

INFOID:0000000010049497

OVERALL SEQUENCE

DETAILED FLOW

JMKIA3449GB

|

|

|

PCS-36 < BASIC INSPECTION > [POWER DISTRIBUTION SYSTEM] DIAGNOSIS AND REPAIR WORKFLOW BASIC INSPECTION DIAGNOSIS AND REPAIR WORKFLOW Work Flow INFOID:0000000010049497 OVERALL SEQUENCE DETAILED FLOW JMKIA3449GB |