Nissan Maxima. Manual - part 840

MA-34

< PERIODIC MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

1. Attach disc rotor to wheel hub using wheel nuts (at two or more

positions).

2. Inspect runout using dial gauge placed at 10 mm (0.39 in) inside

disc edge.

NOTE:

Before measuring, make sure that wheel bearing axial end play

is within the specification. Refer to

.

3. When runout exceeds limit value, displace mounting positions of disc rotor by one hole. Then find a posi-

tion of the minimum value for runout.

4. If runout is outside the specified value after performing the above operation, refinish the disc rotor.

THICKNESS

Check the thickness of the disc rotor using a micrometer. Replace

disc rotor if the thickness is less than the wear limit.

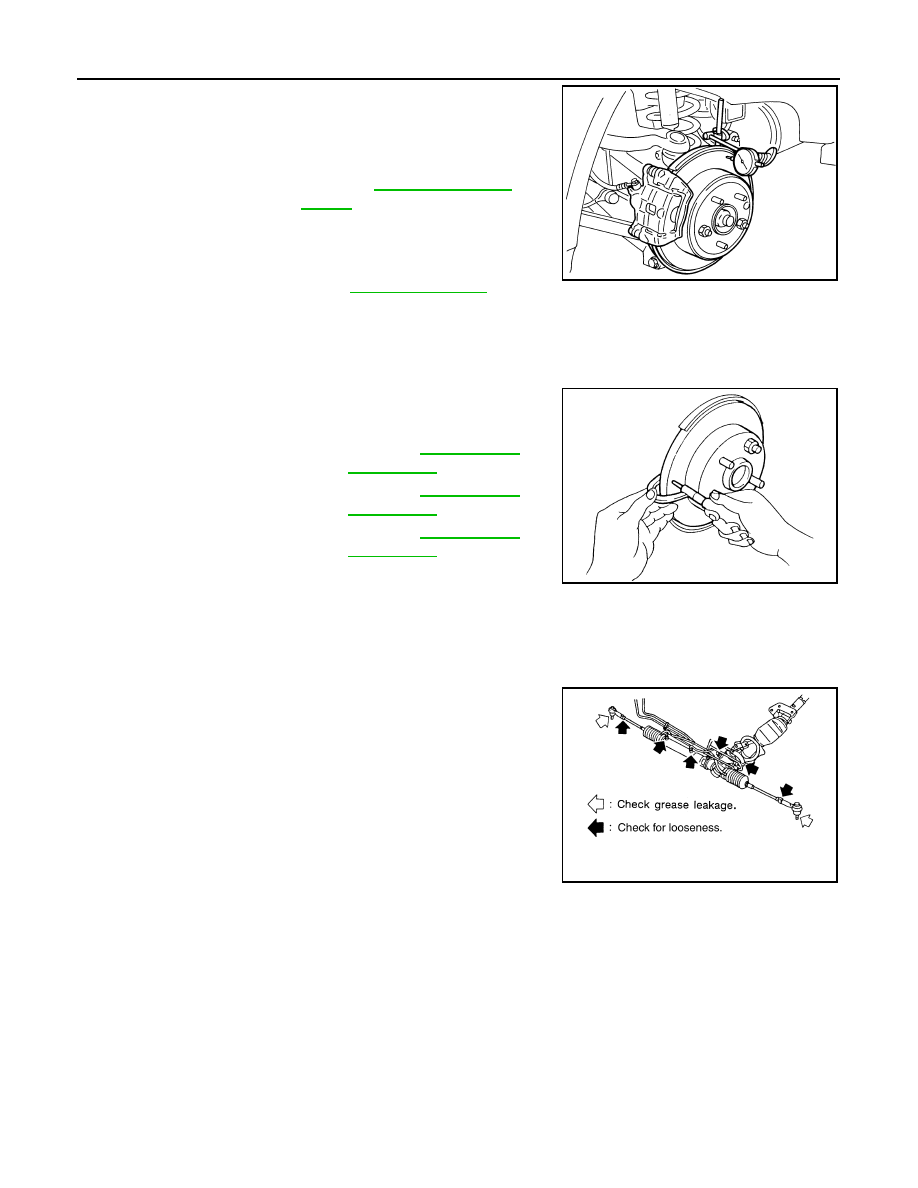

STEERING GEAR AND LINKAGE

STEERING GEAR AND LINKAGE : Inspection

INFOID:0000000009471135

STEERING GEAR

• Check gear housing and boots for looseness, damage and grease

leakage.

• Check connection with steering column for looseness.

STEERING LINKAGE

Check ball joint, dust cover and other component parts for looseness, wear, damage and grease leakage.

POWER STEERING FLUID AND LINES

POWER STEERING FLUID AND LINES : Inspection

INFOID:0000000009471136

FLUID LEVEL

• Check fluid level with engine stopped.

Runout limit

: Refer to

(With it attached to the vehicle)

BRA0697D

Standard thickness

: Refer to

.

Minimum thickness

.

Thickness variation

(Measured at 8 positions)

.

SFIA2284E

SLIA0014E