Nissan Maxima. Manual - part 819

LAN-88

< DTC/CIRCUIT DIAGNOSIS >

[CAN SYSTEM (TYPE 3)]

MAIN LINE BETWEEN ADP AND DLC CIRCUIT

DTC/CIRCUIT DIAGNOSIS

MAIN LINE BETWEEN ADP AND DLC CIRCUIT

Diagnosis Procedure

INFOID:0000000009990321

1.

CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the following terminals and connectors for damage, bend and loose connection (connector side

and harness side).

-

Harness connector B1

-

Harness connector M6

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair the terminal and connector.

2.

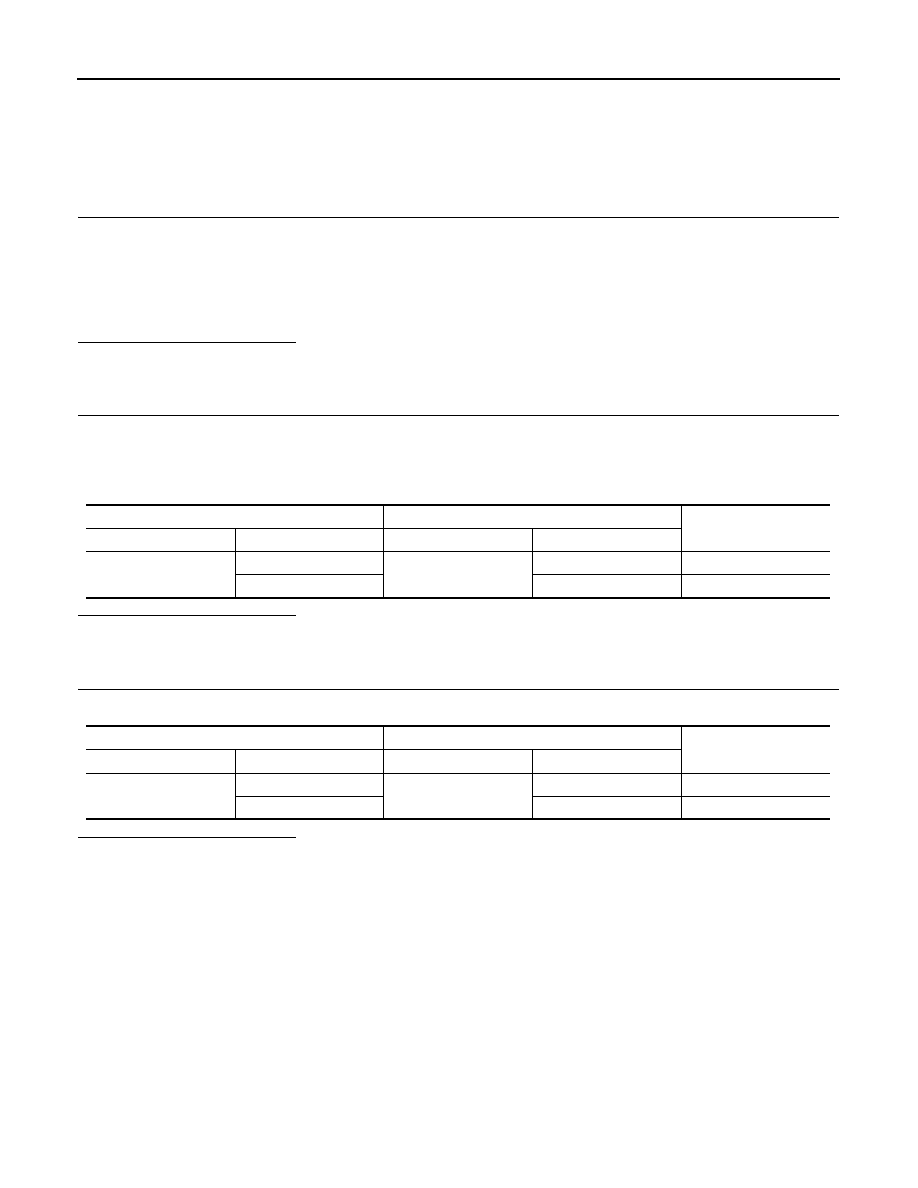

CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Disconnect the following harness connectors.

-

Harness connectors B208 and B32

-

Harness connectors B1 and M6

2. Check the continuity between the harness connectors.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair the main line between the harness connectors B32 and B1.

3.

CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

Check the continuity between the harness connector and the data link connector.

Is the inspection result normal?

YES (Present error)>>Check CAN system type decision again.

YES (Past error)>>Error was detected in the main line between the driver seat control unit and the data link

connector.

NO

>> Repair the main line between the harness connector M6 and the data link connector.

Harness connector

Harness connector

Continuity

Connector No.

Terminal No.

Connector No.

Terminal No.

B32

9

B1

15J

Existed

10

16J

Existed

Harness connector

Data link connector

Continuity

Connector No.

Terminal No.

Connector No.

Terminal No.

M6

15J

M22

6

Existed

16J

14

Existed