Nissan Maxima. Manual - part 709

HAC-12

< SYSTEM DESCRIPTION >

[WITH COLOR DISPLAY]

AUTOMATIC AIR CONDITIONER SYSTEM

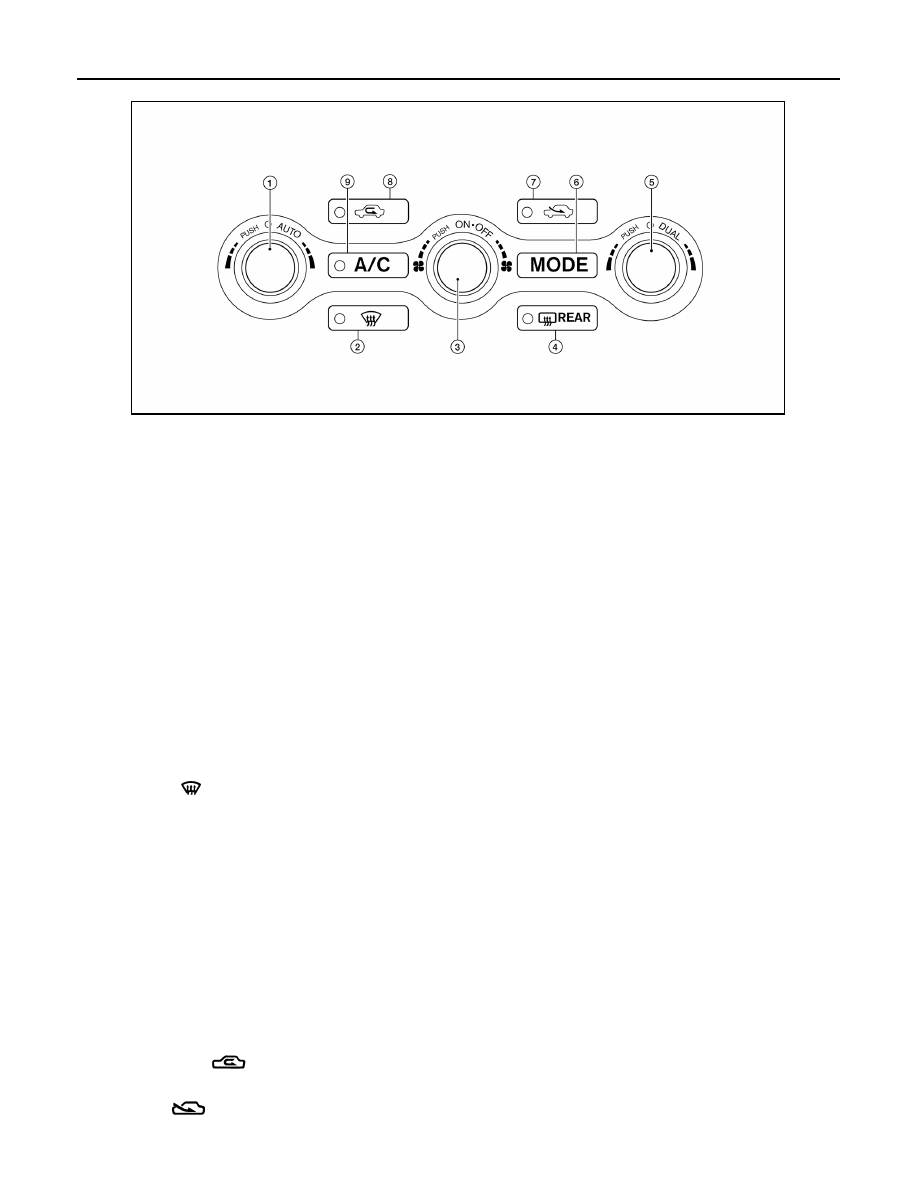

MODE SWITCH

The air discharge outlets are controlled with this switch.

TEMPERATURE CONTROL DIAL (Driver Side)

The set temperature is increased or decreased with this dial.

TEMPERATURE CONTROL DIAL (Passenger Side)

• The set temperature is increased or decreased with this dial.

• When the temperature control dial is turned, DUAL switch indicator is turned ON.

AUTO SWITCH

• The compressor, intake doors, air mix doors, mode doors and blower speed are automatically controlled so

that the in-vehicle temperature will reach, and be maintained at the set temperature selected by the operator.

• When pressing the AUTO switch, air inlet, air outlet, fan speed, and discharge air temperature are automati-

cally controlled.

DEFROSTER (

) SWITCH

Mode doors are set to the defrost position with this switch. Also, intake doors are set to the outside air position,

and compressor turns ON.

A/C SWITCH

Compressor turns ON or OFF with this switch.

(Pressing the A/C switch when the A/C switch is ON turns OFF the A/C switch and compressor.)

FAN CONTROL DIAL

The fan speed is manually controlled with this dial. Seven speeds are available for manual control (as shown

on the display screen).

ON - OFF SWITCH

Compressor and blower turn OFF, intake doors and the mode doors are automatically controlled.

REAR WINDOW DEFOGGER SWITCH

When indicator is ON, rear window is defogged.

RECIRCULATION (

) SWITCH

• When the REC switch is ON, the REC switch indicator is turned ON, and air inlet is set to REC.

FRESH AIR (

) SWITCH

• When the FRE switch is ON, the FRE switch indicator is turned ON, and air inlet is set to FRE.

1.

Temperature control dial (driver

side)/AUTO switch

2.

Defroster switch

3.

ON - OFF switch/fan control dial

4.

Rear window defogger switch

5.

Temperature control dial (passen-

ger)/DUAL mode switch

6.

Mode switch

7.

Fresh air switch

8.

Recirculation switch

9.

A/C ON/OFF switch

AWIIA1375GB