Nissan Maxima. Manual - part 695

HA-6

< PRECAUTION >

PRECAUTIONS

• Connect the pipes at the final stage of the operation when installing an air conditioner in the vehicle.

Do not remove the seal caps of pipes and other components until just before required for connec-

tion.

• Allow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

• Remove moisture thoroughly from the refrigeration system before charging the refrigerant.

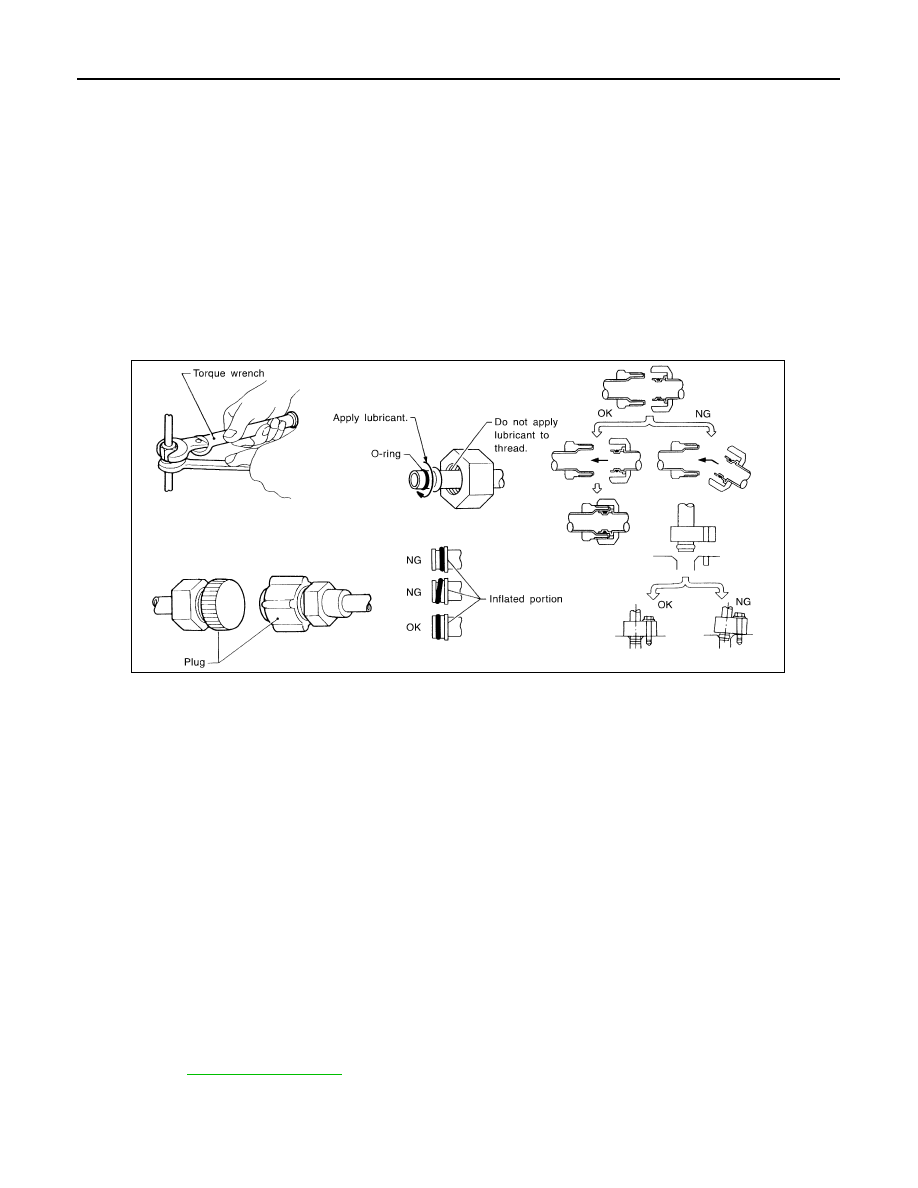

• Always replace used O-rings.

• Apply oil to circle of the O-rings shown in illustration when connecting tube. Be careful not to apply

oil to threaded portion.

• O-ring must be closely attached to the groove portion of tube.

• Be careful not to damage O-ring and tube when replacing the O-ring.

• Connect tube until a click can be heard. Then tighten the nut or bolt by hand. Check that the O-ring is

installed to tube correctly.

• Perform leakage test and make sure that there is no leakage from connections after connecting line.

Disconnect that line and replace the O-ring when the refrigerant leaking point is found. Then tighten

connections of seal seat to the specified torque.

CONTAMINATED REFRIGERANT

Take appropriate steps shown below if a refrigerant other than pure HFC-134a (R-134a) is identified in

a vehicle:

• Explain to the customer that environmental regulations prohibit the release of contaminated refrigerant into

the atmosphere.

• Explain that recovery of the contaminated refrigerant could damage service equipment and refrigerant sup-

ply.

• Suggest the customer return the vehicle to the location of previous service where the contamination may

have occurred.

• In case of repairing, recover the refrigerant using only dedicated equipment and containers. Do not

recover contaminated refrigerant into the existing service equipment. Contact a local refrigerant prod-

uct retailer for available service if the facility does not have dedicated recovery equipment. This refrigerant

must be disposed of in accordance with all federal and local regulations. In addition, replacement of all

refrigerant system components on the vehicle is recommended.

• The air conditioner warranty is void if the vehicle is within the warranty period. Please contact Nissan Cus-

tomer Affairs for further assistance.

COMPRESSOR

CAUTION:

• Plug all openings to prevent moisture and foreign matter from entering.

• Store it in the same way as it is when mounted on the car when the compressor is removed.

• Follow “Maintenance of Oil Quantity in Compressor” exactly when replacing or repairing compres-

sor. Refer to

.

• Keep friction surfaces between clutch and pulley clean. Wipe it off by using a clean waste cloth

moistened with thinner if the surface is contaminated with oil.

RHA861F