Nissan Maxima. Manual - part 526

EC-588

< PRECAUTION >

[VQ35DE]

PRECAUTIONS

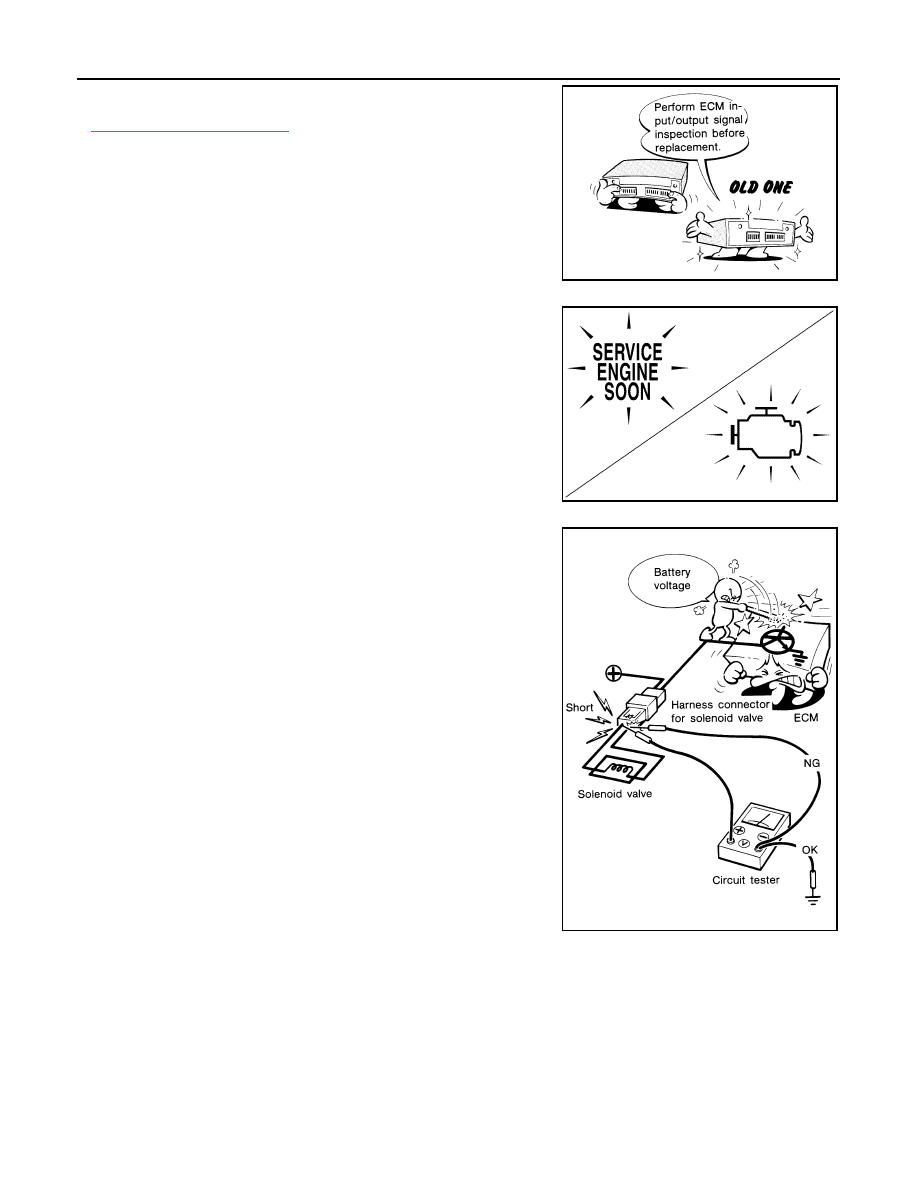

• Before replacing ECM, perform ECM Terminals and Reference

Value inspection and check ECM functions properly. Refer to

.

• Handle mass air flow sensor carefully to avoid damage.

• Never clean mass air flow sensor with any type of detergent.

• Never disassemble electric throttle control actuator.

• Even a slight leakage in the air intake system can cause seri-

ous incidents.

• Never shock or jar the camshaft position sensor (PHASE),

crankshaft position sensor (POS).

• After performing each TROUBLE DIAGNOSIS, perform DTC

Confirmation Procedure or Component Function Check.

The DTC should not be displayed in the DTC Confirmation

Procedure if the repair is completed. The Component Func-

tion Check should be a good result if the repair is completed.

• When measuring ECM signals with a circuit tester, never allow

the two tester probes to contact.

Accidental contact of probes will cause a short circuit and

damage the ECM power transistor.

• Never use ECM ground terminals when measuring input/out-

put voltage. Doing so may result in damage to the ECM's tran-

sistor. Use a ground other than ECM terminals, such as the

ground.

MEF040D

JSBIA1315ZZ

SEF348N