Nissan Maxima. Manual - part 525

EC-584

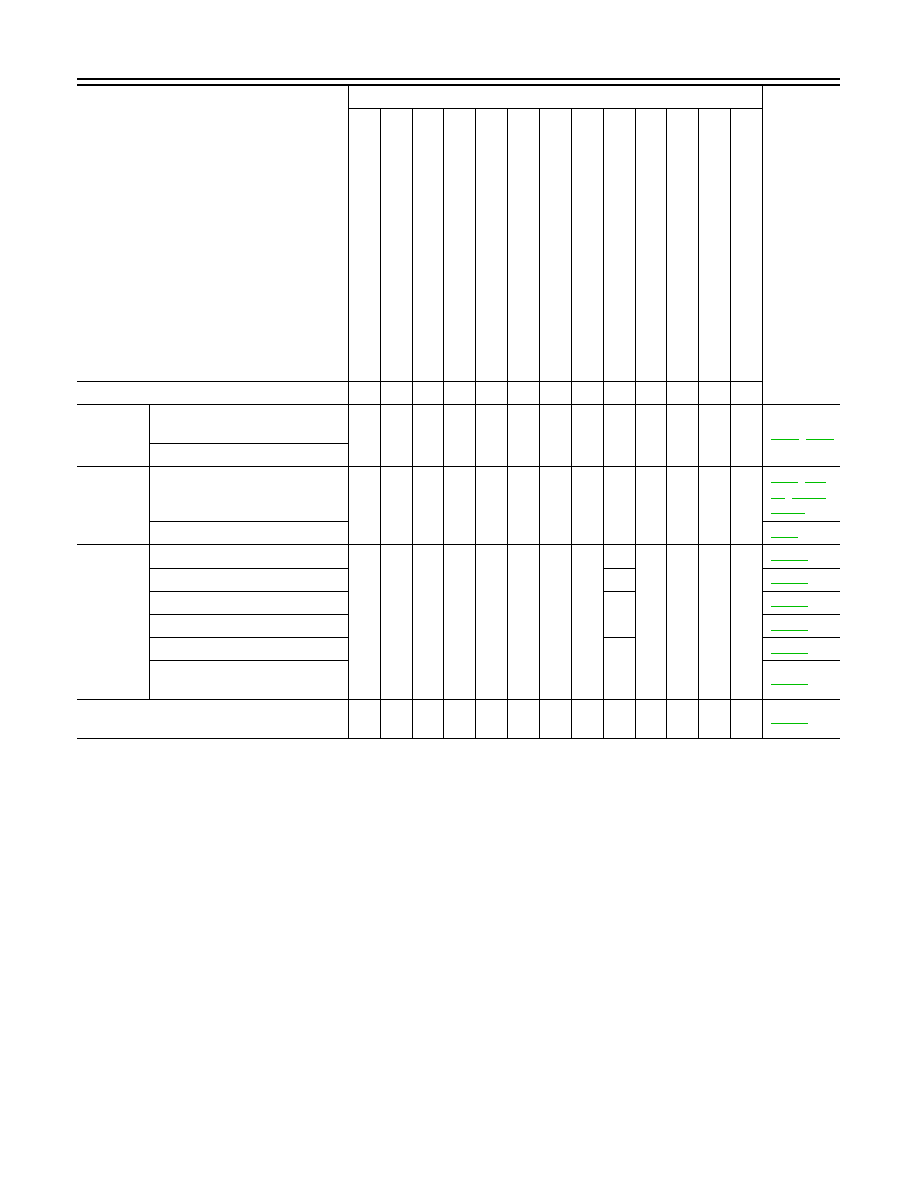

< SYMPTOM DIAGNOSIS >

[VQ35DE]

ENGINE CONTROL SYSTEM SYMPTOMS

1 - 6: The numbers refer to the order of inspection.

Exhaust

Exhaust manifold/Tube/Muffler/

Gasket

5

5

5

5

5

5

5

5

Three way catalyst

Lubrica-

tion

Oil pan/Oil strainer/Oil pump/Oil

filter/Oil gallery/Oil cooler

5

5

5

5

5

5

5

5

,

Oil level (Low)/Filthy oil

Cooling

Radiator/Hose/Radiator filler cap

5

5

5

5

5

5

5

4

5

Thermostat

5

Water pump

Water gallery

Cooling fan

5

Coolant level (Low)/Contaminat-

ed coolant

NVIS (NISSAN Vehicle Immobilizer System —

NATS)

1

1

SYMPTOM

Reference

page

HARD/NO S

TA

R

T/RES

TA

R

T (E

XCP

. HA)

E

N

GINE

ST

ALL

HES

IT

A

TION/SURGING/FLA

T

SPOT

S

P

ARK KNOC

K

/DET

O

NA

TI

ON

LACK OF

POWER/POOR ACCELERA

TION

HIG

H

IDL

E

/L

OW

ID

LE

ROUGH IDLE/HUNTING

ID

LING VI

BRA

T

ION

S

LOW/NO RETU

RN

T

O ID

LE

OVERHEA

T

S

/W

A

TER TEMPERA

T

URE HIG

H

E

XCESSIVE

FUEL CON

S

UMP

T

ION

E

XCESSIVE

OIL

C

O

NSUMP

T

ION

B

A

TTER

Y

DEAD (UNDER CHARGE)

Warranty symptom code

AA

AB

AC

AD

AE

AF

AG AH

AJ

AK

AL

AM HA