Nissan Maxima. Manual - part 464

EC-340

< DTC/CIRCUIT DIAGNOSIS >

[VQ35DE]

P0448 EVAP CANISTER VENT CONTROL VALVE

YES

>> GO TO 7.

NO

>> GO TO 6.

6.

DETECT MALFUNCTIONING PART

Check the following.

• EVAP canister for damage

• EVAP hose between EVAP canister and drain filter for clogging or poor connection

>> Repair hose or replace EVAP canister. Refer to

FL-14, "Removal and Installation (EVAP Canis-

.

7.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR CONNECTOR

1. Disconnect EVAP control system pressure sensor harness connector.

2. Check that water is not inside connectors.

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> Replace EVAP control system pressure sensor. Refer to

FL-17, "Removal and Installation"

.

8.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-340, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> Replace EVAP control system pressure sensor. Refer to

FL-17, "Removal and Installation"

.

9.

CHECK INTERMITTENT INCIDENT

GI-41, "Intermittent Incident"

>> INSPECTION END

Component Inspection

INFOID:0000000010095023

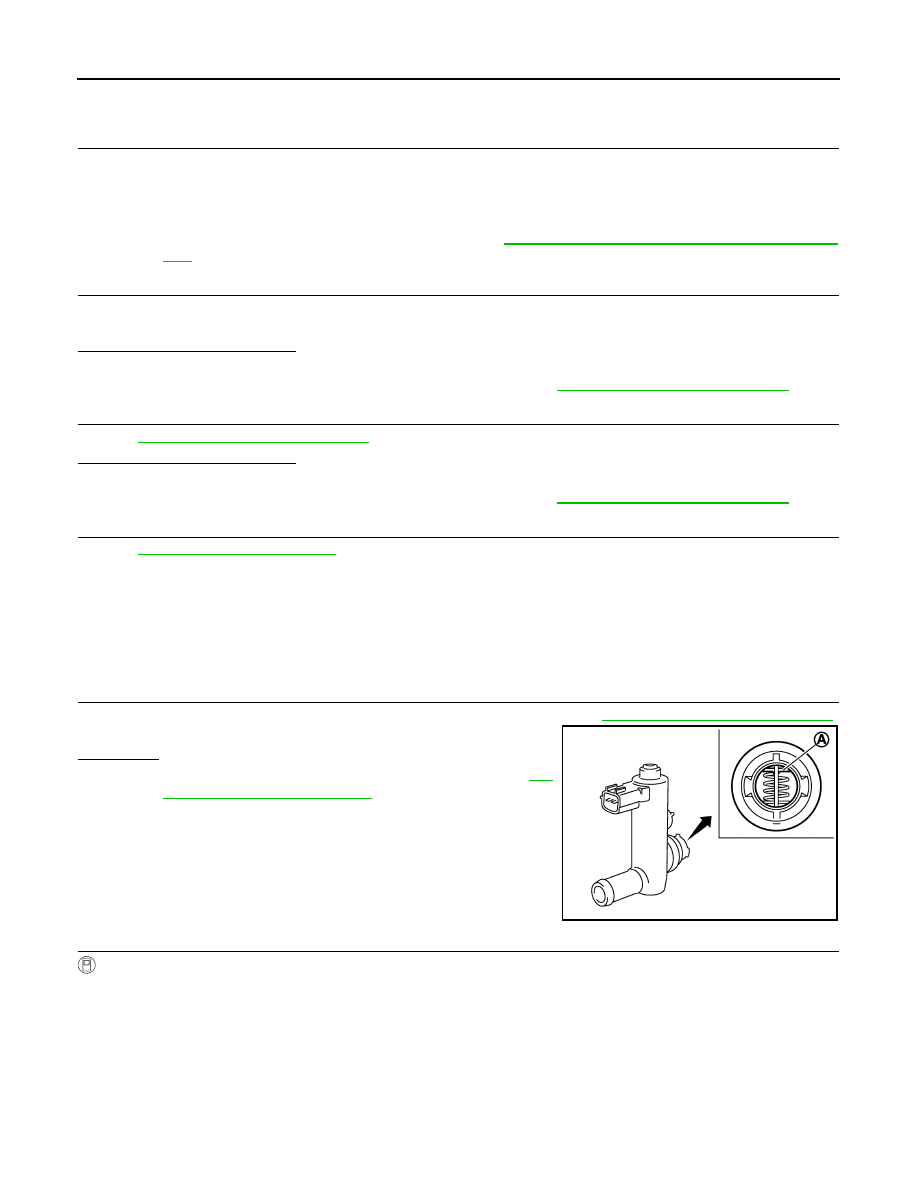

EVAP CANISTER VENT CONTROL VALVE

1.

CHECK EVAP CANISTER VENT CONTROL VALVE-I

1. Remove EVAP canister vent control valve from EVAP canister. Refer to

FL-16, "Removal and Installation"

.

2. Check portion (A) of EVAP canister vent control valve for rust.

Is it rusted?

YES

>> Replace EVAP canister vent control valve. Refer to

16, "Removal and Installation"

.

NO

>> GO TO 2.

2.

CHECK EVAP CANISTER VENT CONTROL VALVE-II

With CONSULT

1. Reconnect harness connectors disconnected.

2. Turn ignition switch ON.

3. Perform “VENT CONTROL/V” in “ACTIVE TEST” mode.

JMBIA0168ZZ