Nissan Maxima. Manual - part 457

EC-312

< DTC/CIRCUIT DIAGNOSIS >

[VQ35DE]

P0441 EVAP CONTROL SYSTEM

1.

PERFORM COMPONENT FUNCTION CHECK

Without CONSULT

1. Lift up drive wheels.

2. Start engine (VDC switch OFF) and warm it up to normal operating temperature.

3. Turn ignition switch OFF, wait at least 10 seconds.

4. Turn ignition switch ON.

5. Turn ignition switch OFF, wait at least 10 seconds.

6. Start engine and wait at least 70 seconds.

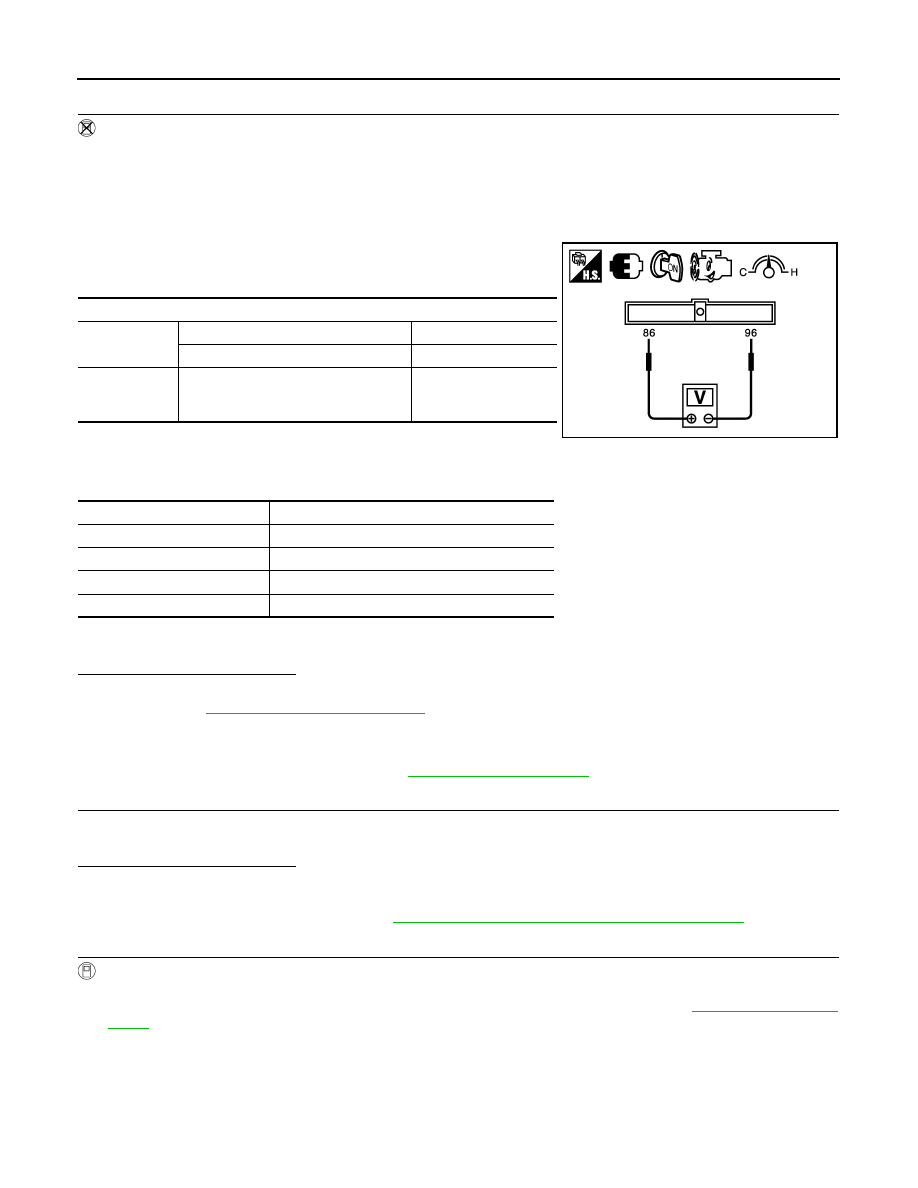

7. Set voltmeter probes to ECM harness connector terminals under

the following conditions.

8. Check EVAP control system pressure sensor value at idle speed

and note it.

9. Establish and maintain the following conditions for at least 1 minute.

10. Verify that EVAP control system pressure sensor value stays 0.1 V less than the value at idle speed (mea-

sured at step 6) for at least 1 second.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Go to

Diagnosis Procedure

INFOID:0000000010095003

Regarding Wiring Diagram information, refer to

.

1.

CHECK EVAP CANISTER

1. Turn ignition switch OFF.

2. Check EVAP canister for cracks.

Is the inspection result normal?

YES-1 >> With CONSULT: GO TO 2.

YES-2 >> Without CONSULT: GO TO 3.

NO

>> Replace EVAP canister. Refer to

FL-14, "Removal and Installation (EVAP Canister)"

.

2.

CHECK PURGE FLOW

With CONSULT

1. Disconnect vacuum hose connected to EVAP canister purge volume control solenoid valve at EVAP ser-

vice port and install vacuum gauge. For the location of EVAP service port, refer to

.

2. Start engine and let it idle.

3. Select “PURG VOL CONT/V” in “ACTIVE TEST” mode with CONSULT.

4. Touch “Qd” and “Qu” on CONSULT screen to adjust “PURG VOL CONT/V” opening and check vacuum

existence.

ECM

Connector

+

–

Terminal

Terminal

E10

86

(EVAP control system pressure sensor

signal)

96

(Sensor ground)

Air conditioner switch

ON

Head lamp switch

ON

Rear window defogger switch

ON

Engine speed

Approx. 3,000 rpm

Gear position

Any position other than P, N or R

JMBIA1870ZZ