Nissan Maxima. Manual - part 439

EC-240

< DTC/CIRCUIT DIAGNOSIS >

[VQ35DE]

P0138, P0158 HO2S2

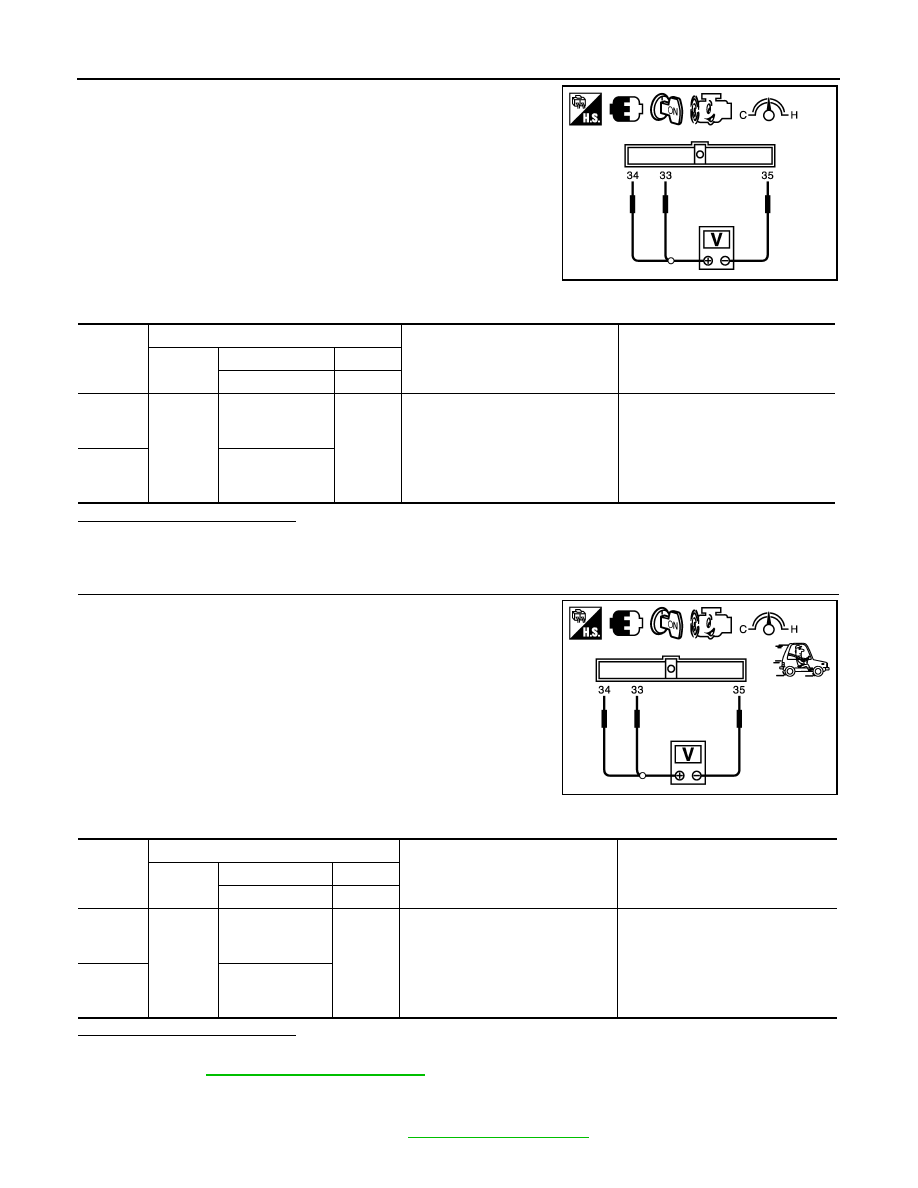

Check the voltage between ECM harness connector terminals under

the following conditions.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> GO TO 3.

3.

PERFORM COMPONENT FUNCTION CHECK-III

Check the voltage between ECM harness connector terminals under

the following conditions.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Go to

Diagnosis Procedure

INFOID:0000000010094947

Regarding Wiring Diagram information, refer to

.

JMBIA1866ZZ

DTC

ECM

Condition

Voltage

Connec-

tor

+

–

Terminal

Terminal

P0138

F13

33

[HO2S2 (bank 1)

signal]

35

(Sensor

ground)

Keeping engine speed at idle for 10

minutes

The voltage should be below 0.18 V

at least once during this procedure.

P0158

34

[HO2S2 (bank 2)

signal]

JMBIA1867ZZ

DTC

ECM

Condition

Voltage

Connec-

tor

+

–

Terminal

Terminal

P0138

F13

33

[HO2S2 (bank 1)

signal]

35

(Sensor

ground)

Coasting from 80 km/h (50 MPH) in D

position

The voltage should be below 0.18 V

at least once during this procedure.

P0158

34

[HO2S2 (bank 2)

signal]