Nissan Maxima. Manual - part 421

EC-168

< DTC/CIRCUIT DIAGNOSIS >

[VQ35DE]

P0014, P0024 EVT CONTROL

>> INSPECTION END

4.

CHECK EVT CONTROL POSITION SENSOR

EC-402, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Replace malfunctioning EVT control position sensor. Refer to

5.

CHECK CRANKSHAFT POSITION SENSOR

EC-299, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Replace crankshaft position sensor. Refer to

EM-37, "Removal and Installation (Upper Oil Pan)"

6.

CHECK CAMSHAFT POSITION SENSOR

EM-37, "Removal and Installation (Upper Oil Pan)"

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> Replace malfunctioning camshaft position sensor. Refer to

.

7.

CHECK CAMSHAFT (EXH)

Check the following.

• Accumulation of debris to the signal plate of camshaft rear end

• Chipping signal plate of camshaft rear end

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> Remove debris and clean the signal plate of camshaft

rear end or replace camshaft. Refer to

8.

CHECK TIMING CHAIN INSTALLATION

Check service records for any recent repairs that may cause timing chain misalignment.

Are there any service records that may cause timing chain misalignment?

YES

>> Check timing chain installation. Refer to

EM-64, "Removal and Installation"

.

NO

>> GO TO 9.

9.

REPLACE EVT CONTROL PULLEY ASSEMBLY

1. Replace camshaft sprocket (EXH) and EVT control magnet retarder.

EM-64, "Removal and Installation"

EM-54, "Removal and Installation"

2. Perform

EC-23, "EXHAUST VALVE TIMING CONTROL LEARNING : Special Repair Requirement"

>> INSPECTION END

10.

CHECK INTERMITTENT INCIDENT

GI-41, "Intermittent Incident"

>> INSPECTION END

Component Inspection

INFOID:0000000010094870

1.

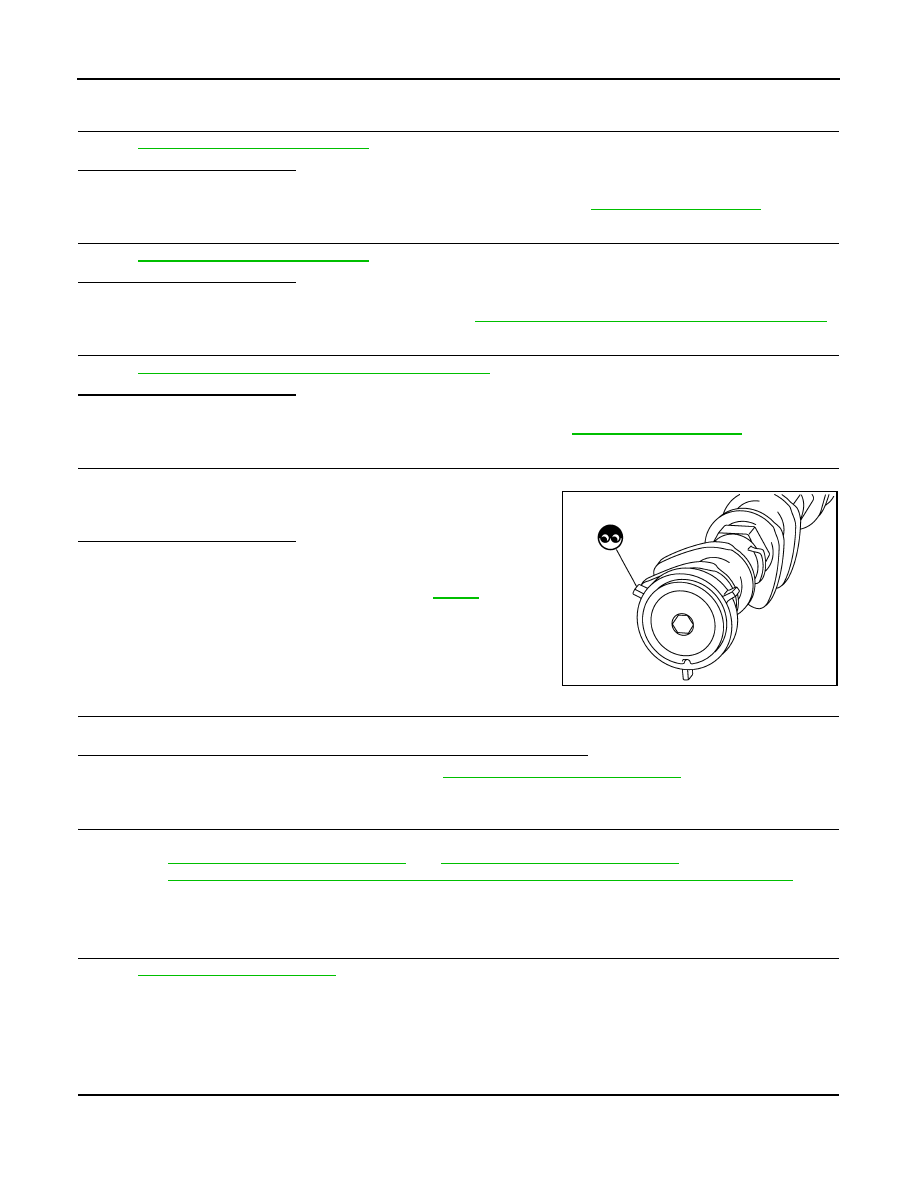

CHECK EXHAUST VALVE TIMING CONTROL MAGNET RETARDER

1. Turn ignition switch OFF.

2. Disconnect exhaust valve timing control magnet retarder harness connector.

JMBIA0059ZZ