Nissan Maxima. Manual - part 302

CO-20

< REMOVAL AND INSTALLATION >

[VQ35DE]

WATER PUMP

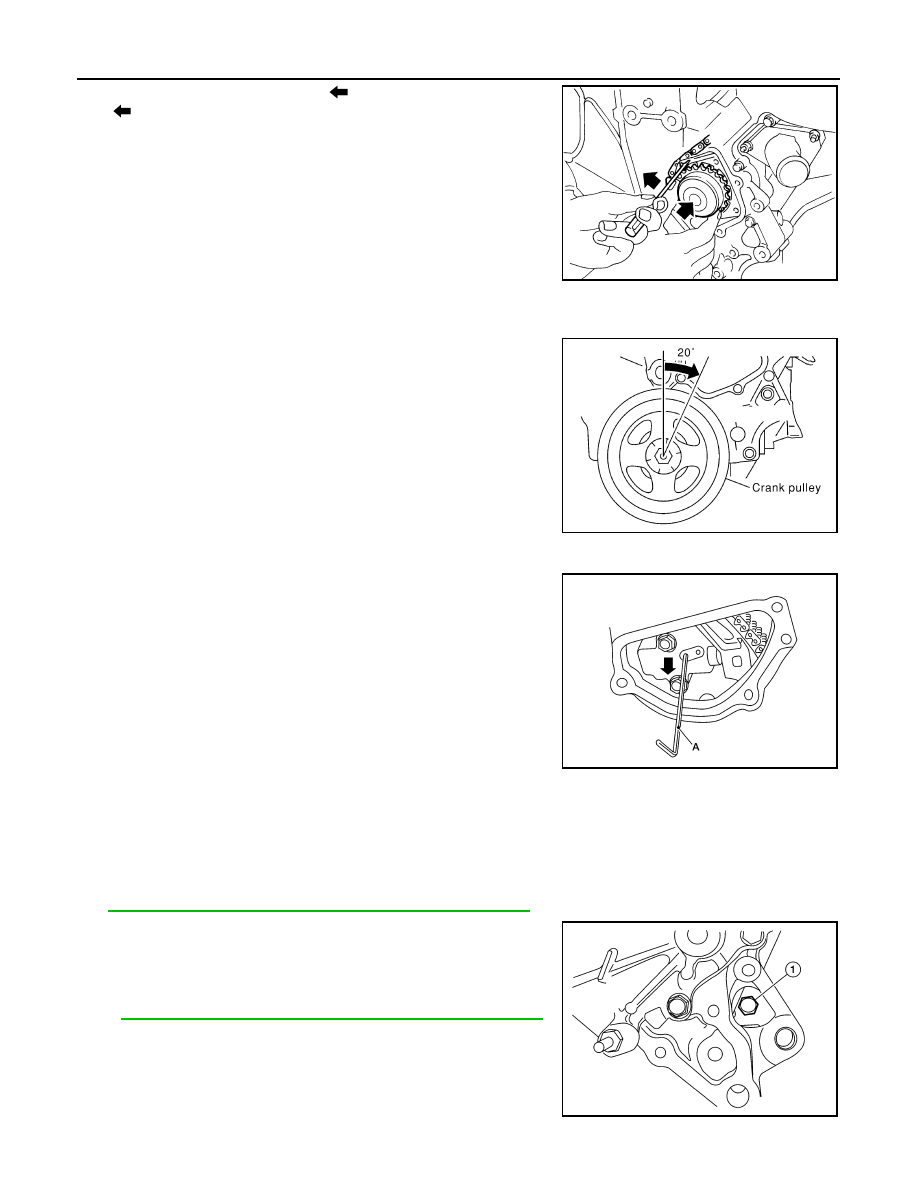

3. Hold timing chain to the side (

) and install the water pump

(

).

CAUTION:

Do not allow cylinder block to interfere with the O-rings

when installing the water pump.

• Check that timing chain and water pump sprocket are

engaged.

• Tighten water pump bolts alternately and evenly to specifica-

tion.

4. Remove dust and foreign material completely from installation area of timing chain tensioner and rear tim-

ing chain case.

5. Turn the crankshaft pulley approximately 20

° clockwise so that

the timing chain on the timing chain tensioner side is loose.

6. Apply engine oil to the oil feed hole and timing chain tensioner and install the timing chain tensioner.

7. Remove the stopper pin (A).

8. Install intake valve timing control solenoid valve cover (RH) (bank 1) and water pump cover.

a. Before installing, remove all traces of liquid gasket from mating surface of water pump cover and intake

valve timing control solenoid valve cover (RH) (bank 1) using a scraper.

Also remove traces of liquid gasket from the mating surface of the front cover.

b. Apply a continuous bead of liquid gasket to mating surface of intake valve timing control solenoid valve

cover (RH) (bank 1) and water pump cover. Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-21, "Recommended Chemical Products and Sealants"

.

9. Install cylinder block front drain plug (1) on water pump side of

cylinder block.

• Apply liquid gasket to the threads of cylinder block front drain

plug.

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-21, "Recommended Chemical Products and Sealants"

.

10. Installation of remaining components is in the reverse order of removal.

SLC031B

PBIC0848E

AWBIA0905ZZ

Cylinder block front

drain plug

: 9.8 N·m (1.0 kg-m, 87 in-lb)

AWBIA0902ZZ