Nissan Maxima. Manual - part 281

BRM-36

< REMOVAL AND INSTALLATION >

REPLACEMENT OPERATIONS

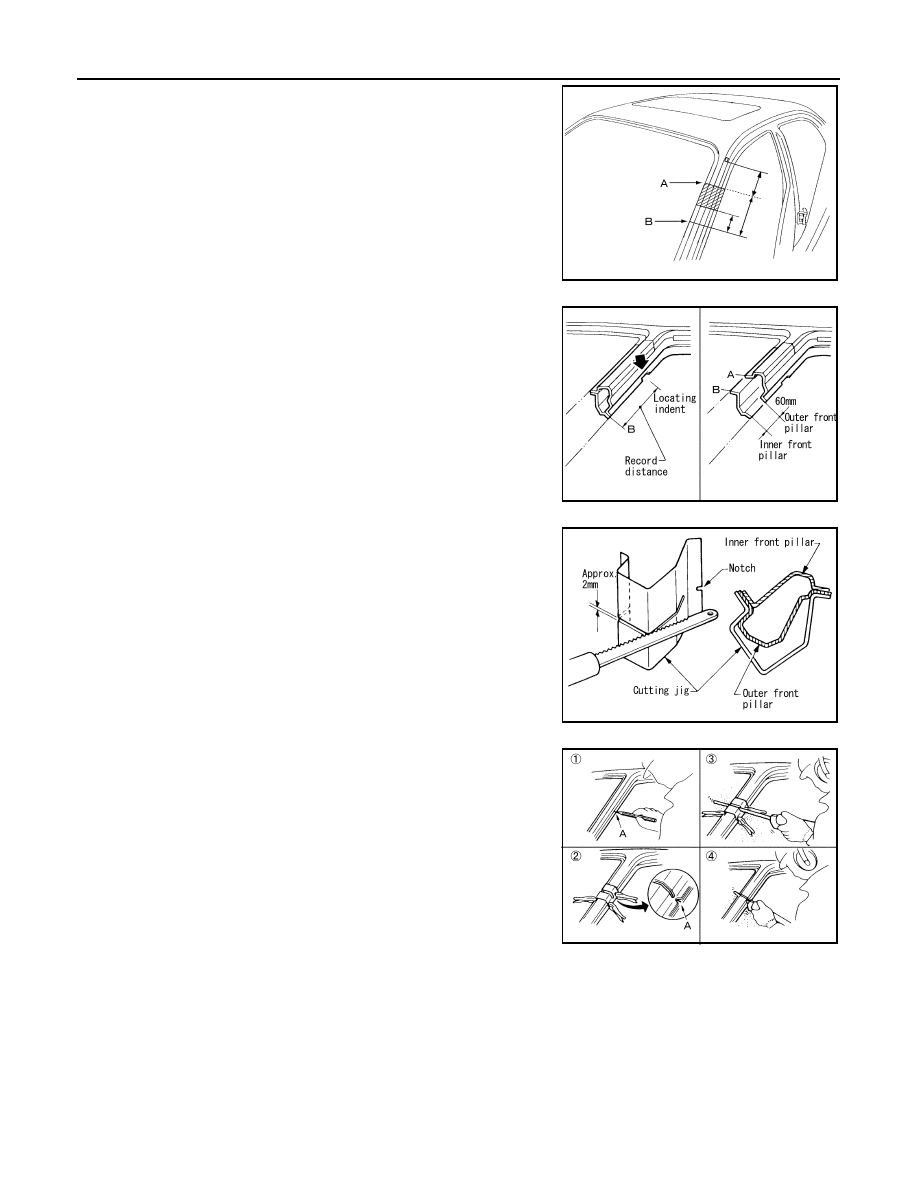

• Front pillar butt joint can be determined anywhere within shaded

area as shown in the figure. The best location for the butt joint is at

position A due to the construction of the vehicle. Refer to the front

pillar section.

• Determine cutting position and record distance from the locating

indent. Use this distance when cutting the service part. Cut outer

front pillar over 60 mm above inner front pillar cut position.

• Prepare a cutting jig to make outer pillar easier to cut. Also, this will

permit service part to be accurately cut at joint position.

• An example of cutting operation using a cutting jig is as follows.

1. Mark cutting lines.

A: Cut position of outer pillar

B: Cut position of inner pillar

2. Align cutting line with notch on jig. Clamp jig to pillar.

3. Cut outer pillar along groove of jig. (At position A)

4. Remove jig and cut remaining portions.

5. Cut inner pillar at position B in same manner.

FOAM REPAIR

During factory assembly, foam insulators are installed in certain body panels and locations around the vehicle.

Use the following procedure(s) to replace any factory-installed foam insulators.

Urethane Foam Applications

Use commercially available spray for sealant (foam material) repair of material used on vehicle. Read instruc-

tions on product for fill procedures.

Fill Procedures

1. Fill procedures after installation service part.

• Remove foam material remaining on vehicle side.

PIIA0150E

PIIA0151E

PIIA0152E

PIIA0153E