Nissan Altima HL32 Hybrid. Manual - part 692

P3004-131

HBC-517

< COMPONENT DIAGNOSIS >

D

E

F

G

H

I

J

K

L

M

A

B

HBC

N

O

P

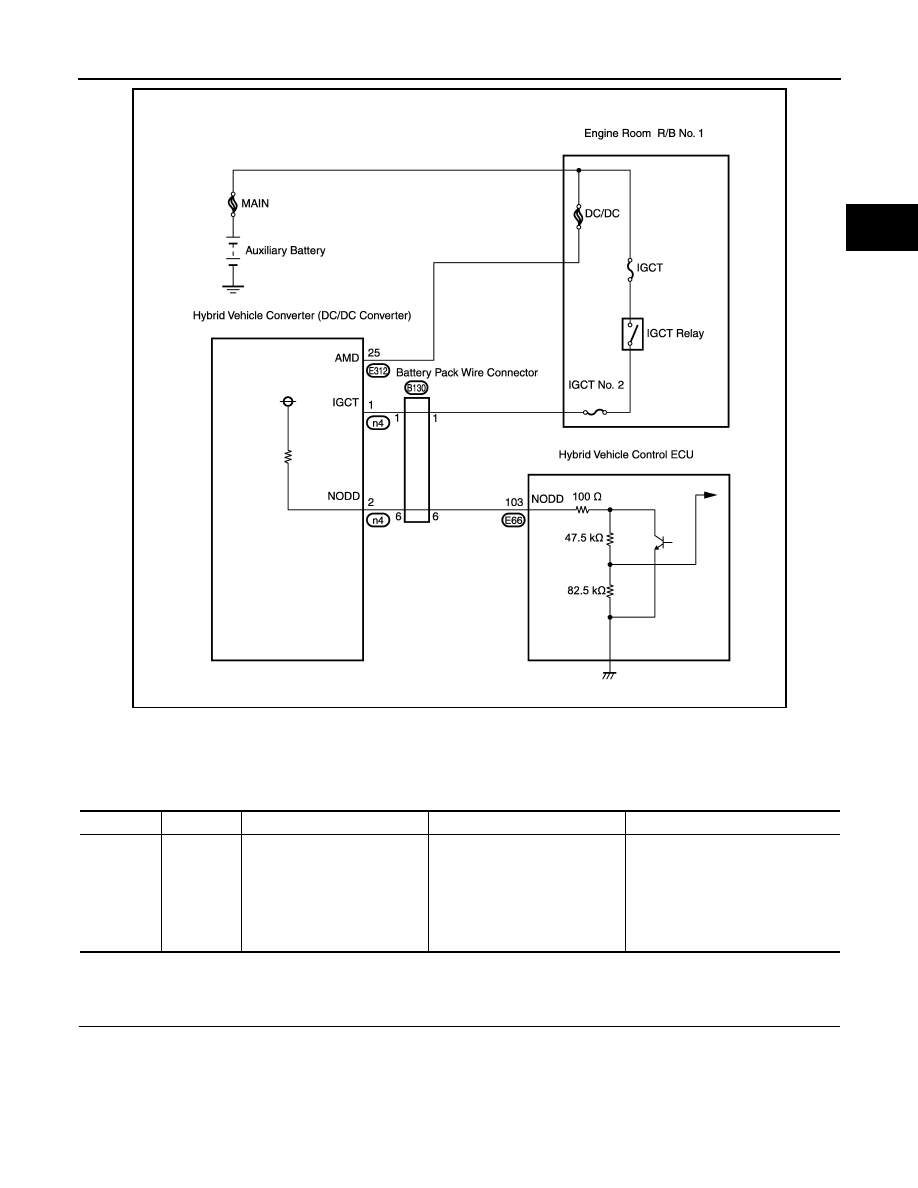

DTC Logic

INFOID:0000000004212122

DTC DETECTION LOGIC

Diagnosis Procedure

INFOID:0000000004212123

1.

PRECONDITIONING

• Before inspecting the high-voltage system or disconnecting the low voltage connector of the inverter with

converter assembly, take safety precautions such as wearing insulated gloves and removing the service

plug grip to prevent electrical shocks. After removing the service plug grip, put it in your pocket to prevent

other technicians from accidentally reconnecting it while you are working on the high-voltage system.

• After disconnecting the service plug grip, wait for at least 10 minutes before touching any of the high-voltage

connectors or terminals.

JMCIA0125GB

DTC No.

INF code

Trouble diagnosis name

DTC detecting condition

Possible cause

P3004

131

Power cable malfunction

The inverter voltage is not boost-

ed during precharge (time from

when SMRP turns on until when

SMRG turns on).

• HV relay assembly

• Frame wire

• Inverter with converter assembly

• HV battery

• Wire harness or connector

• Hybrid vehicle converter (DC/DC

converter)