Nissan Altima HL32 Hybrid. Manual - part 626

P0A78-284

HBC-253

< COMPONENT DIAGNOSIS >

D

E

F

G

H

I

J

K

L

M

A

B

HBC

N

O

P

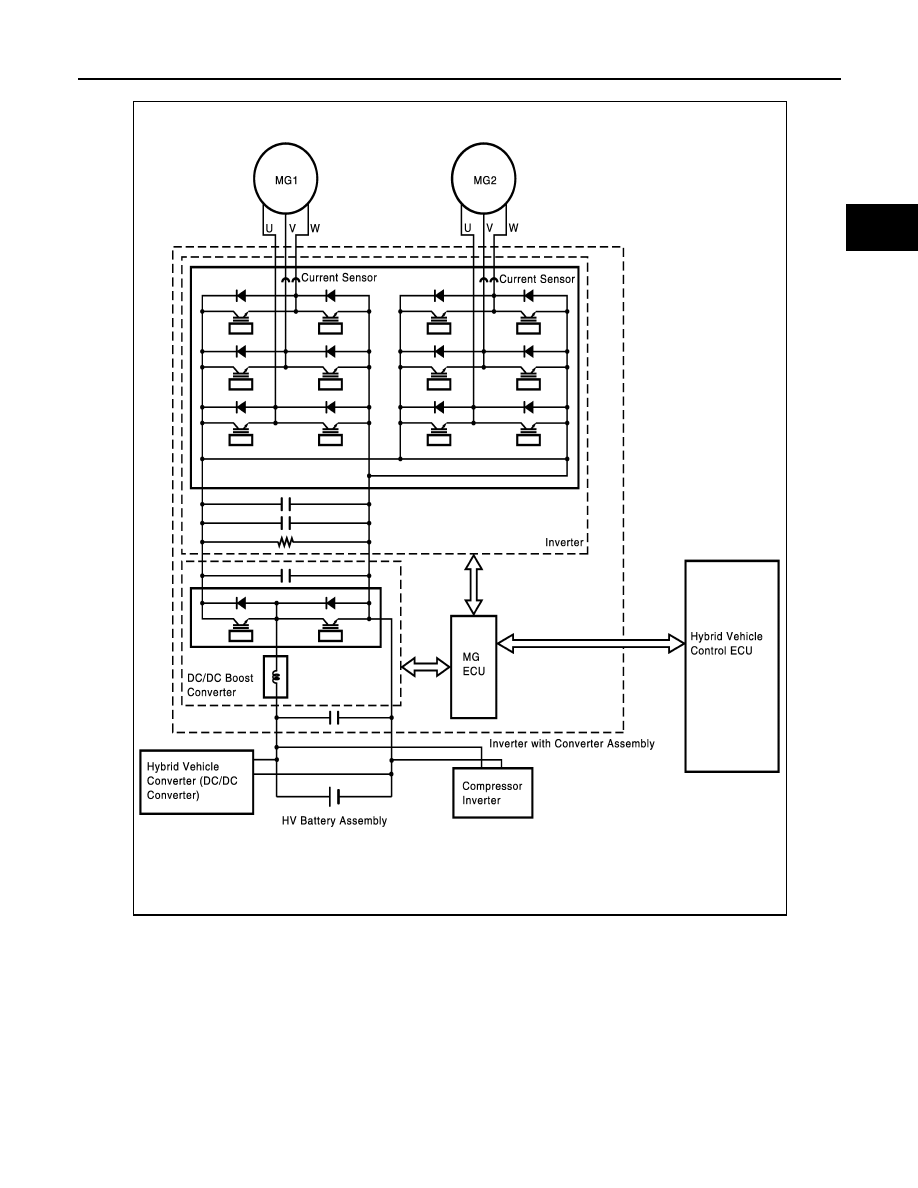

The MG ECU monitors the inverter voltage and detects malfunctions.

DTC Logic

INFOID:0000000004211925

DTC DETECTION LOGIC

If the motor inverter overheats, or has a circuit malfunction or internal short, the inverter transmits this informa-

tion to the MFIV terminal of the MG ECU via the motor inverter fail signal line.

If the motor inverter overheats, it transmits an inverter fail signal to the MG ECU. Upon receiving this signal,

the hybrid vehicle control ECU will illuminate the MIL and set a DTC.

JMCIA0099GB