Nissan Altima HL32 Hybrid. Manual - part 462

TRANSVERSE LINK

FSU-11

< ON-VEHICLE REPAIR >

C

D

F

G

H

I

J

K

L

M

A

B

FSU

N

O

P

TRANSVERSE LINK

Removal and Installation

INFOID:0000000004523245

REMOVAL

1. Remove wheel and tire using power tool. Refer to

2. Remove steering knuckle from transverse link. Refer to

.

3. Remove mounting nuts and washers on lower portion of stabilizer connecting rod.

4. Slightly loosen transverse link mounting bolts.

5. Remove transverse link mounting bolts and nuts, and remove transverse link from suspension member.

INSPECTION AFTER REMOVAL

Visual Inspection

Check transverse link and bushing for deformation, cracks, and other damage. Replace the entire transverse

link assembly if cracks, deformation or any other damage is found.

Ball Joint Inspection

CAUTION:

Before measurement, move the ball joint at least ten times by hand to check for smooth movement.

Swing Torque Inspection

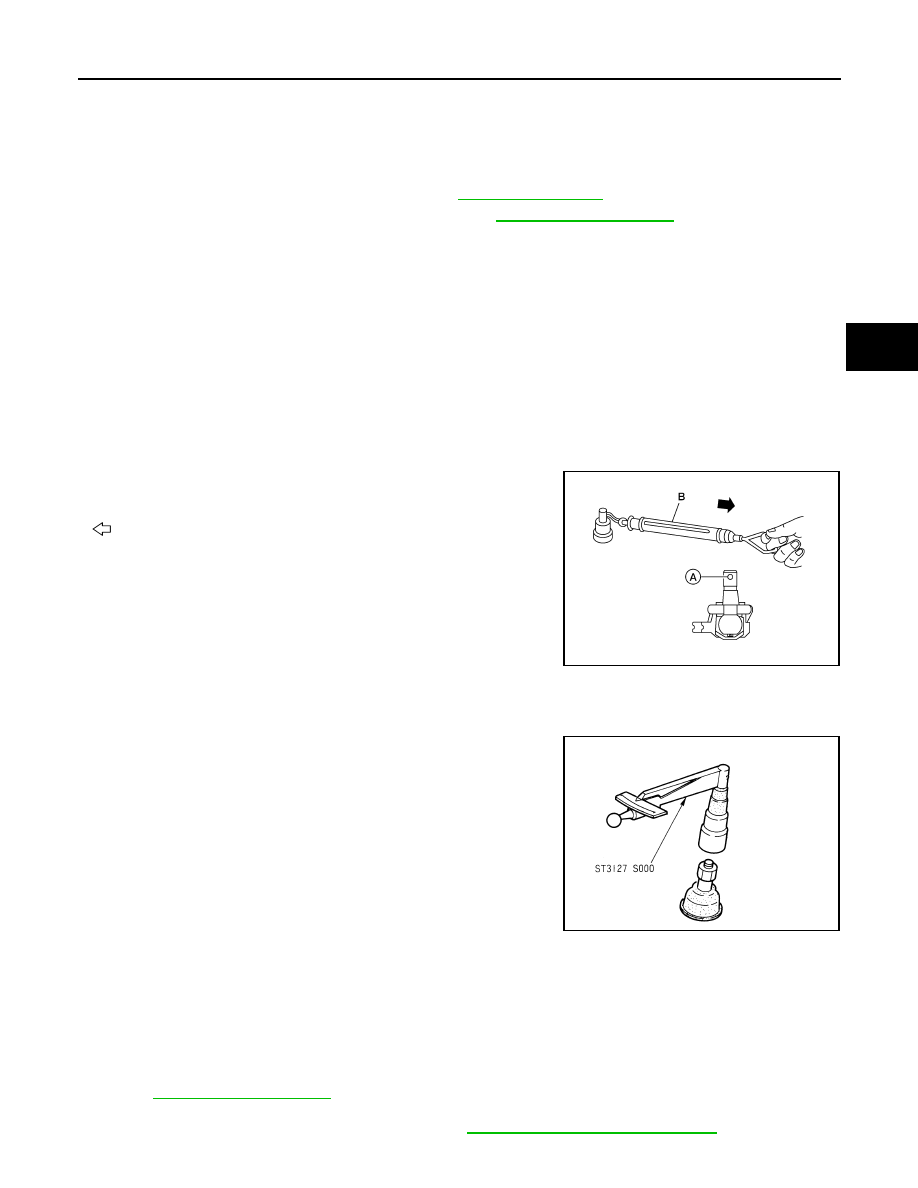

• Hook Tool (B) at cotter pin mounting hole (A). Confirm Tool (B)

measurement value is within specifications when ball stud begins

moving.

: Front

• If the value is outside the standard, replace transverse link.

Rotating Torque Inspection

• Attach mounting nut to ball stud. Check that rotating torque is

within specifications using Tool.

• If the value is outside the standard, replace transverse link.

Axial End Play Inspection

• Move tip of ball joint in axial direction to check for looseness.

• If any looseness is noted, replace transverse link.

INSTALLATION

Installation is in the reverse order of removal.

• Refer to

for tightening torque specifications.

• Tighten transverse link mounting bolts with vehicle unladen and all four tire on flat, level ground.

• After installation, check the wheel alignment. Refer to

FSU-6, "Inspection and Adjustment"

.

Tool number

: — (J-44372)

Swing torque

: 0.50 - 3.4 N·m (0.06 - 0.34 kg-m,

5 - 30 in-lb)

Measurement on Tool

: 7.94 - 53.97 N (0.81 - 5.50 kg,

1.79 - 12.2 lb)

AWGIA0066ZZ

Tool number

: ST3127S000 (J-25765-A)

Rotating torque

: 0.50 - 3.4 N·m (0.06 - 0.34 kg-m,

5 - 30 in-lb)

FAC1021D

Axial end play : 0.1 mm (0.004 in) or less