Nissan Altima HL32 Hybrid. Manual - part 390

EM-74

< REMOVAL AND INSTALLATION >

[QR25DE]

ENGINE ASSEMBLY

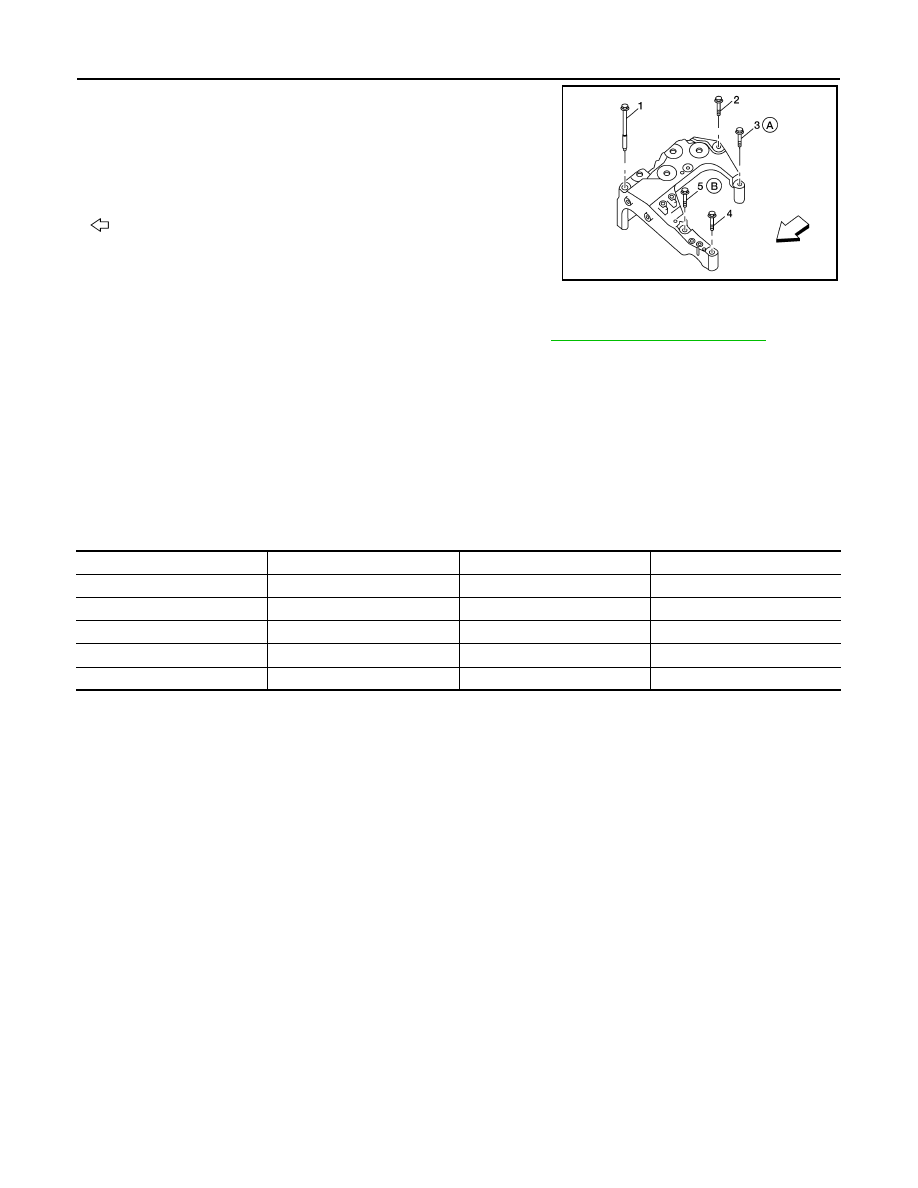

• Install the RH engine mounting bracket bolts in the following steps:

- First install bolts (A) and (B) loosely.

- Install and tighten the five RH engine mounting bracket bolts to

specification in the order as shown.

-

: Front

INSPECTION AFTER INSTALLATION

• Before starting the hybrid system, check oil/fluid levels including hybrid system coolant and hybrid system

oil. If less than required quantity, fill to the specified level. Refer to

MA-10, "Fluids and Lubricants"

• Use procedure below to check for fuel leakage.

- Turn ignition switch ON (with hybrid system stopped). With fuel pressure applied to fuel piping, check for fuel

leakage at connection points.

- Start the hybrid system. With engine speed increased, check again for fuel leakage at connection points.

- Run hybrid system to check for unusual noise and vibration.

- Warm up hybrid system thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids

including hybrid system oil and hybrid system coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down hybrid system, again check oils/fluids including hybrid system oil and hybrid system cool-

ant. Refill to specified level, if necessary.

• Summary of the inspection items:

*Transaxle/CVT fluid, brake fluid, etc.

RH engine mounting bracket bolt : 48.2 N·m (4.9 kg-m,

36 ft-lb)

ALBIA0541ZZ

Item

Before starting engine

Engine running

After engine stopped

Hybrid system coolant

Level

Leakage

Level

Hybrid system oil

Level

Leakage

Level

Other oils and fluids*

Level

Leakage

Level

Fuel

Leakage

Leakage

Leakage

Exhaust gas

—

Leakage

—