Nissan Altima HL32 Hybrid. Manual - part 389

EM-70

< ON-VEHICLE REPAIR >

[QR25DE]

CYLINDER HEAD

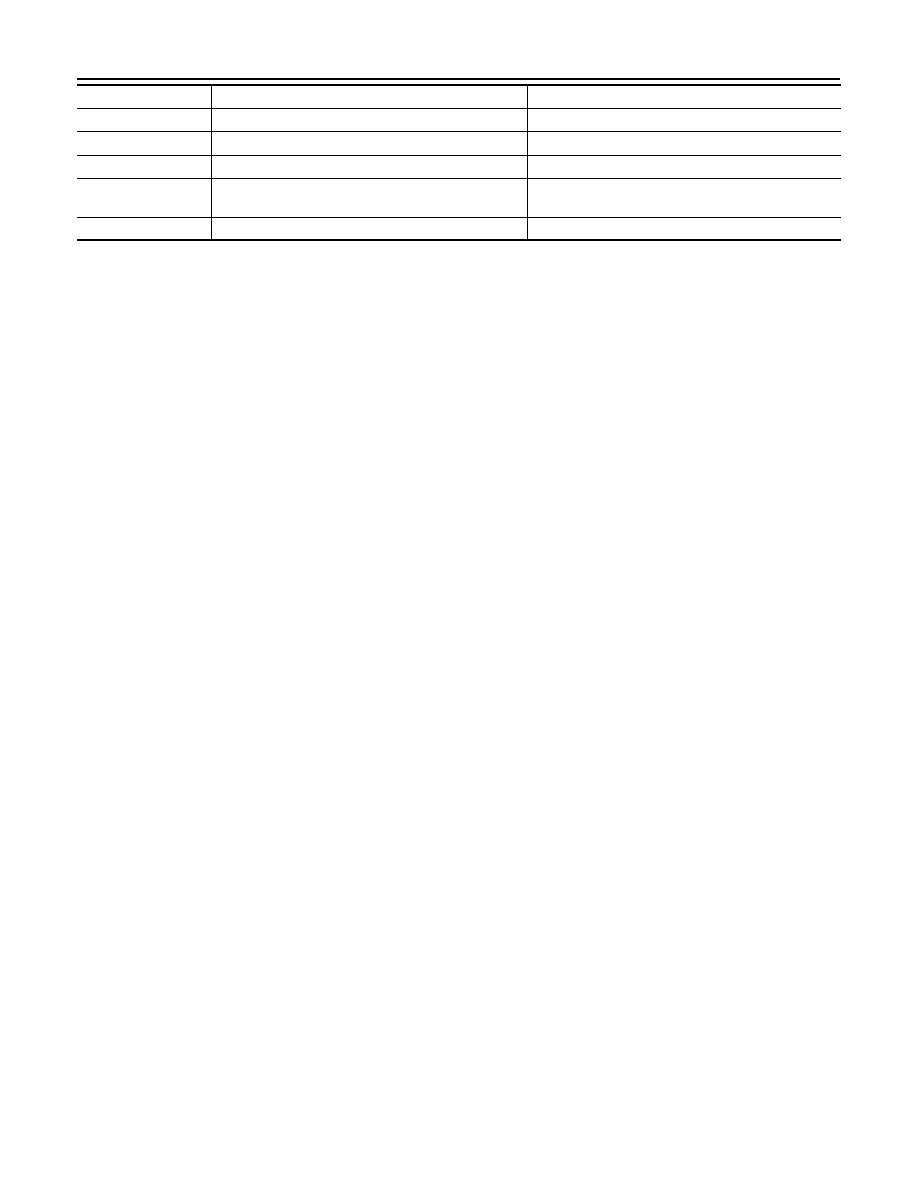

STANDARD

INTAKE (identification color: pink)

EXHAUST (identification color: green)

Free height

43.72 - 43.92 mm (1.7213 - 1.7291 in)

45.29 - 45.49 mm (1.7831 - 1.7909 in)

Installation height

35.30 mm (1.390 in)

35.30 mm (1.390 in)

Installation load

151 - 175 N (15.4 - 17.8 kg-f, 34 - 39 lb-f)

151 - 175 N (15.4 - 17.8 kg-f, 34 - 39 lb-f)

Height during valve

open

25.30 mm (0.9961 in)

26.76 mm (1.0535 in)

Load with valve open

351 - 394 N (35.8 - 40.2 kg-f, 79 - 89 lb-f)

318 - 362 N (32.4 - 37.8 kg-f, 72 - 81 lb-f)