Nissan Altima HL32 Hybrid. Manual - part 379

EM-30

< ON-VEHICLE REPAIR >

[QR25DE]

EXHAUST MANIFOLD AND THREE WAY CATALYST

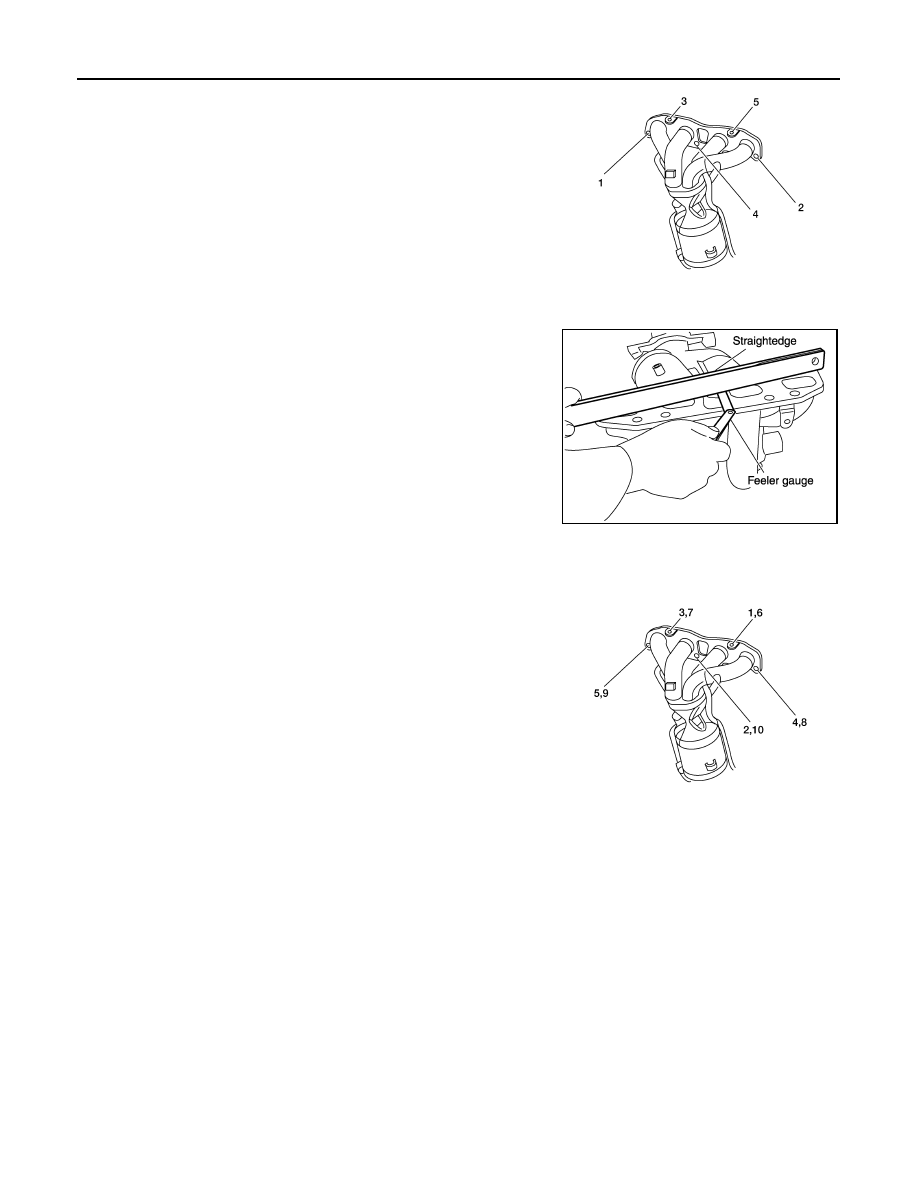

7. Loosen the nuts in the reverse order as shown, on the exhaust

manifold and three way catalyst assembly.

8. Remove the exhaust manifold and three way catalyst assembly

and gasket. Discard the gasket.

INSPECTION AFTER REMOVAL

Surface Distortion

• Use a reliable straightedge and feeler gauge to check the flatness

of exhaust manifold fitting surface.

INSTALLATION

Installation is in the reverse order of removal.

Tightening Exhaust Manifold Nuts

• Tighten the nuts to specification in the numerical order as shown,

on the exhaust manifold and three way catalyst assembly.

Installation of Air Fuel Ratio (A/F) Sensor 1

Clean the air fuel ratio (A/F) sensor 1 threads with the Tool, then apply the anti-seize lubricant to the threads

before installing the air fuel ratio (A/F) sensor 1.

CAUTION:

Do not over-tighten the air fuel ratio (A/F) sensor 1. Doing so may cause damage to the air fuel ratio (A/

F) sensor 1, resulting in a malfunction and the MIL coming on.

AWBIA0559ZZ

Limit

: 0.3 mm (0.012 in)

KBIA0046E

AWBIA0560ZZ

Tool number

: J-43897 - 18

: J-43897 - 12