Nissan Altima HL32 Hybrid. Manual - part 375

EM-14

< ON-VEHICLE MAINTENANCE >

[QR25DE]

DRIVE BELTS

DRIVE BELTS

Checking Drive Belts

INFOID:0000000004211235

WARNING:

Inspect the drive belt only when the Hybrid System is off.

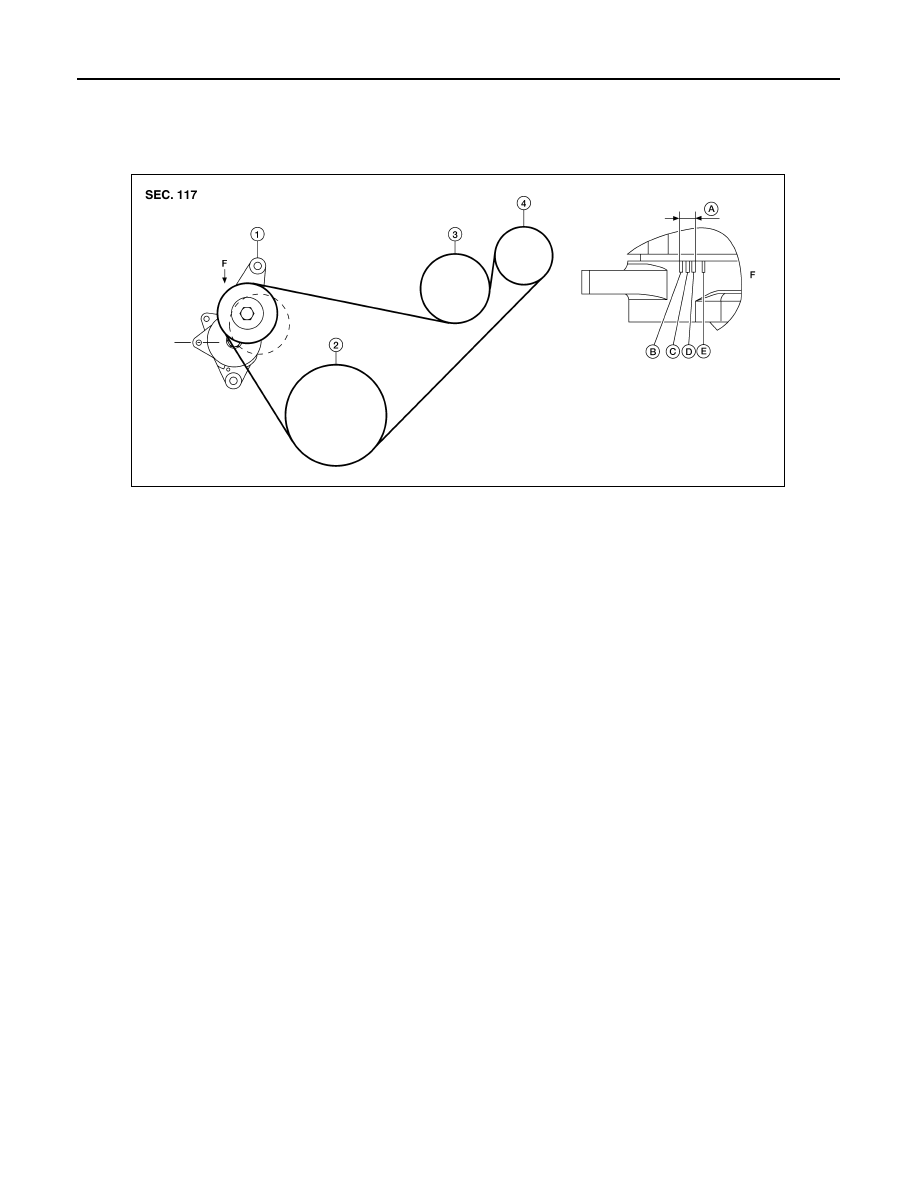

• Make sure that the stamp mark of drive belt auto-tensioner is within the usable range.

NOTE:

• Check the drive belt auto-tensioner indicator (notch) when the engine is cold.

• When the new drive belt is installed, the range should be (A) as shown.

• Visually check entire belt for wear, damage or cracks.

• If the indicator is out of allowable use range or belt is damaged, replace the belt.

Tension Adjustment

INFOID:0000000004211236

• Belt tension is not manually adjustable, it is automatically adjusted by the drive belt auto-tensioner.

Removal and Installation of Drive Belt

INFOID:0000000004211237

REMOVAL

1. Remove the fender protector side cover (RH).

2. Securely hold the hexagonal part in pulley center of drive belt auto-tensioner, using suitable tool.

WARNING:

• Avoid placing hand in a location where pinching may occur if the holding tool accidentally

comes off.

CAUTION:

• Do not loosen the auto-tensioner pulley bolt. (Do not turn it counterclockwise) If turned counter-

clockwise, the complete auto-tensioner must be replaced as a unit, including pulley.

3. Insert a rod approximately 6 mm (0.24 in) in diameter through the rear of tensioner into retaining boss to

lock tensioner pulley.

• Leave tensioner pulley arm locked until belt is installed again.

4. Loosen auxiliary drive belt from water pump pulley in sequence, and remove it.

INSTALLATION

1.

Drive belt auto-tensioner

2.

Crankshaft

3.

Water pump

4.

Idler pulley

A.

Water pump belt working range B.

Minimum belt length

C.

Nominal position

D.

Maximum belt length

E.

Maximum belt length +0.8%

F.

View F

AWBIA0586ZZ