Nissan Altima HL32 Hybrid. Manual - part 369

EC-460

< PRECAUTION >

[QR25DE]

PRECAUTIONS

General Precautions

INFOID:0000000004211671

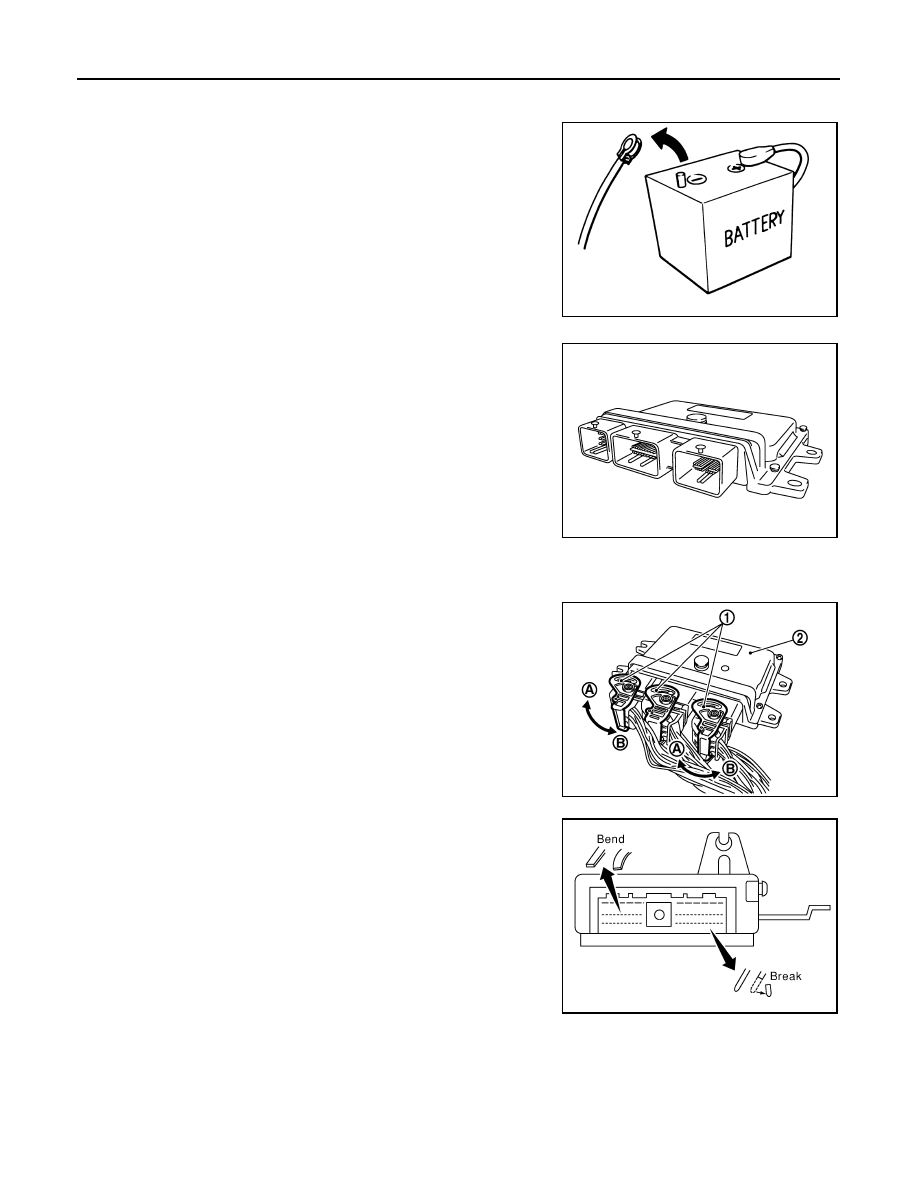

• Always use a 12 volt battery as power source.

• Do not attempt to disconnect battery cables while engine is

running.

• Before connecting or disconnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect negative bat-

tery cable. Failure to do so may damage the ECM because

battery voltage is applied to ECM even if ignition switch is

turned OFF.

• Before removing parts, turn ignition switch OFF and then dis-

connect battery ground cable.

• Do not disassemble ECM.

• If a battery cable is disconnected, the memory will return to

the ECM value.

The ECM will now start to self-control at its initial value.

Engine operation can vary slightly when the terminal is dis-

connected. However, this is not an indication of a malfunc-

tion. Do not replace parts because of a slight variation.

• If the battery is disconnected, the following emission-related

diagnostic information will be lost within 24 hours.

- Diagnostic trouble codes

- 1st trip diagnostic trouble codes

- Freeze frame data

- 1st trip freeze frame data

- System readiness test (SRT) codes

- Test values

• When connecting ECM harness connector (1), fasten (B) it

securely with a lever as far as it will go as shown in the figure.

• When connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM pin

terminal, when connecting pin connectors.

• Securely connect ECM harness connectors.

A poor connection can cause an extremely high (surge) volt-

age to develop in coil and condenser, thus resulting in dam-

age to ICs.

• Keep engine control system harness at least 10 cm (4 in) away

from adjacent harness, to prevent engine control system mal-

functions due to receiving external noise, degraded operation

of ICs, etc.

• Keep engine control system parts and harness dry.

SEF289H

2.

ECM

A.

Loosen

PBIA9222J

PBIB2947E

PBIB0090E