Nissan Altima HL32 Hybrid. Manual - part 296

EC-168

< COMPONENT DIAGNOSIS >

[QR25DE]

P0117, P0118 ECT SENSOR

2. Disconnect engine coolant temperature sensor harness connector.

3. Remove engine coolant temperature sensor.

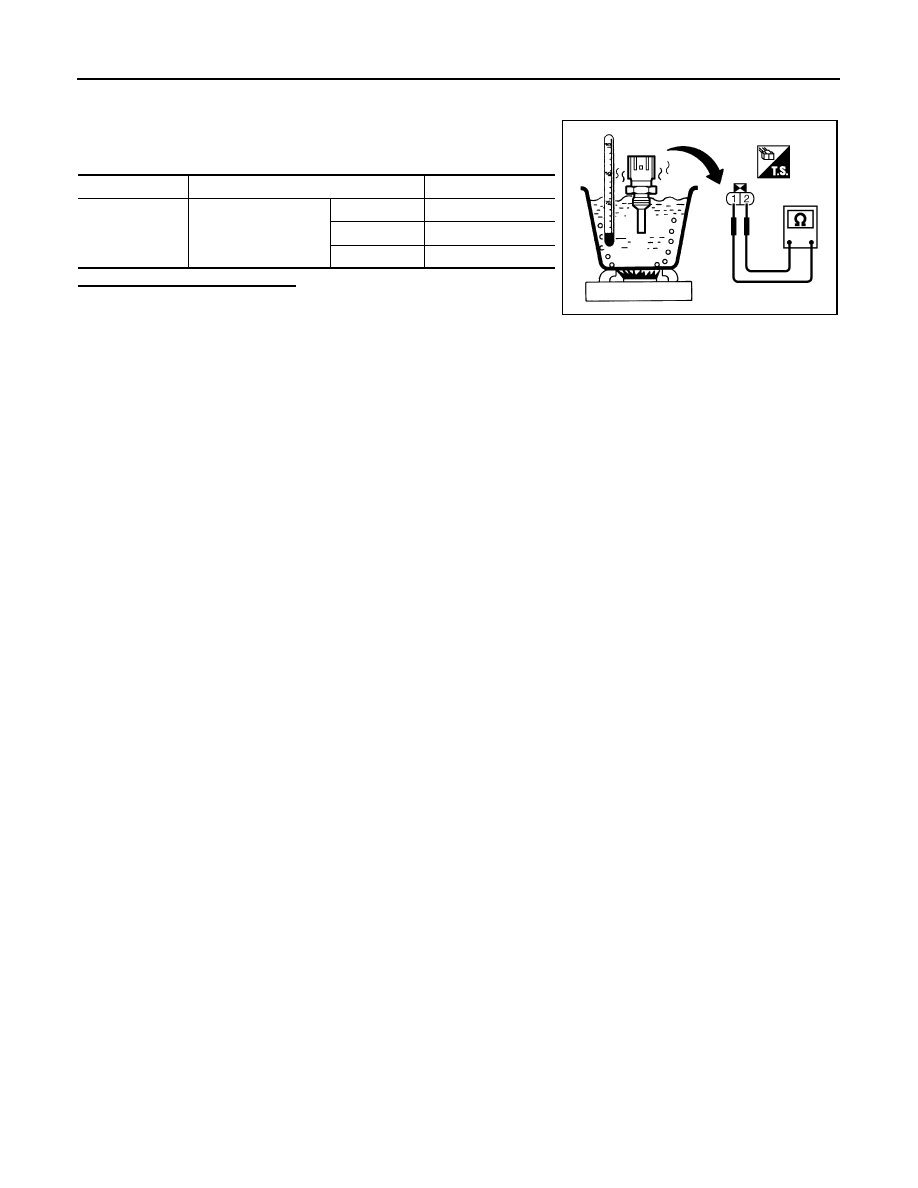

4. Check resistance between engine coolant temperature sensor

terminals by heating with hot water as shown in the figure.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace engine coolant temperature sensor.

Terminals

Condition

Resistance

1 and 2

Temperature

°C (°F)

20 (68)

2.37 - 2.63 k

Ω

50 (122)

0.68 - 1.00 k

Ω

90 (194)

0.236 - 0.260 k

Ω

PBIB2005E