Content .. 1062 1063 1064 1065 ..

Nissan Altima HL32 Hybrid. Manual - part 1064

C16A1 EPS DC/DC CONVERTER

STC-35

< COMPONENT DIAGNOSIS >

C

D

E

F

H

I

J

K

L

M

A

B

STC

N

O

P

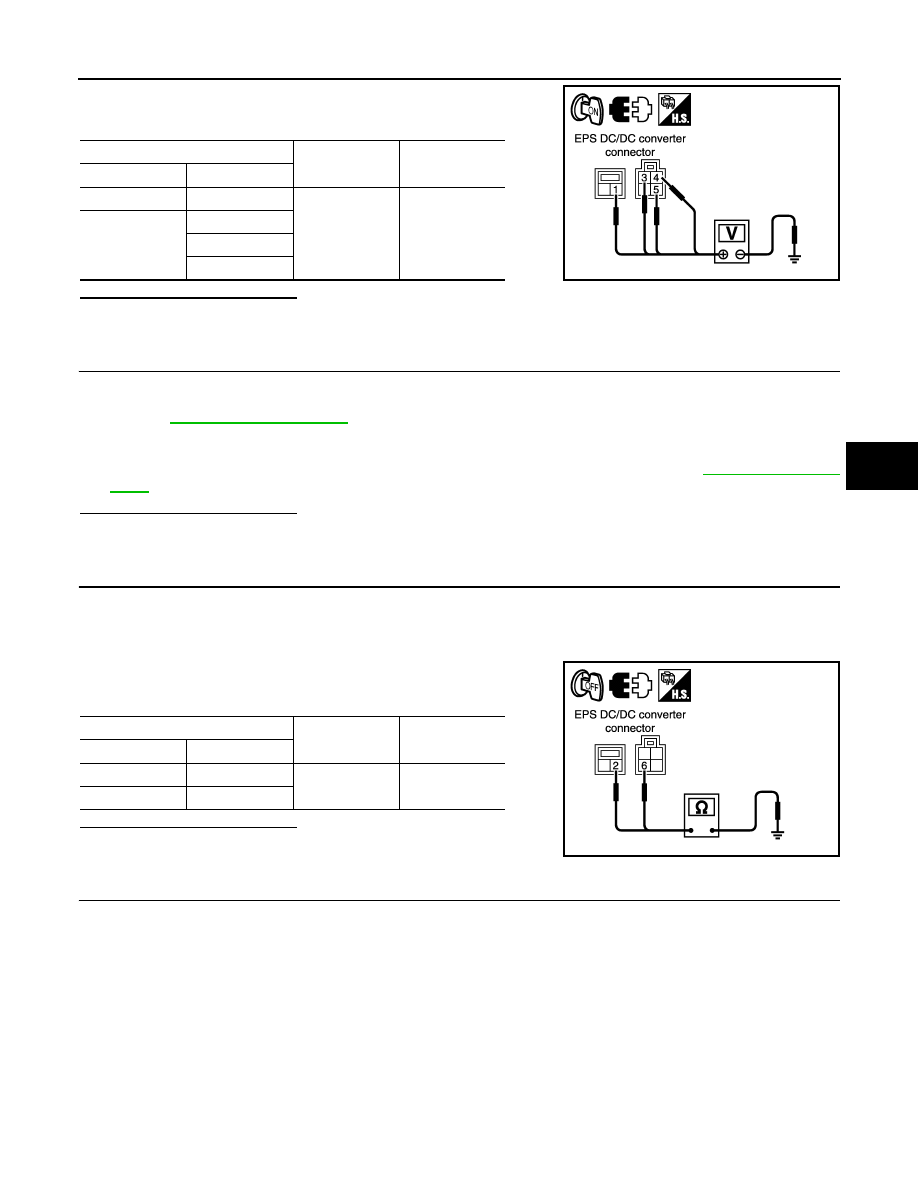

8. Check the voltage between EPS DC/DC converter harness con-

nectors and ground.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace the harnesses or connectors.

4.

CHECK EPS DC/DC CONVERTER INSTALLATION CONDITION

1. Turn the ignition switch OFF.

2. Check the installation condition of the EPS DC/DC converter ground wire connected to the vehicle body.

CAUTION:

EPS DC/DC converter ground wire is securely installed to the vehicle body.

3. Check the installation condition of the EPS DC/DC converter assembly. Refer to

.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair each installation condition.

5.

CHECK EPS DC/DC CONVERTER GROUND

1. Turn the ignition switch OFF.

2. Disconnect EPS DC/DC converter harness connectors.

CAUTION:

Turn the ignition switch OFF before disconnecting or reconnecting any harness connector.

3. Check the continuity between EPS DC/DC converter harness

connectors and ground.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Repair or replace the harnesses or connectors.

6.

CHECK HV BATTERY CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect EPS DC/DC converter harness connector and HV battery harness connector.

CAUTION:

Turn the ignition switch OFF before disconnecting or reconnecting any harness connector.

EPS DC/DC converter

Ground

Voltage (Ap-

prox.)

Connector

Terminal

E303

1

Ground

1 V or less

E305

3

4

5

PGIA0097E

EPS DC/DC converter

Ground

Continuity

Connector

Terminal

E304

2

Ground

Existed

E305

6

PGIA0098E