Nissan Frontier. Manual - part 855

HA-12

< PREPARATION >

PREPARATION

Commercial Service Tool

INFOID:0000000009478577

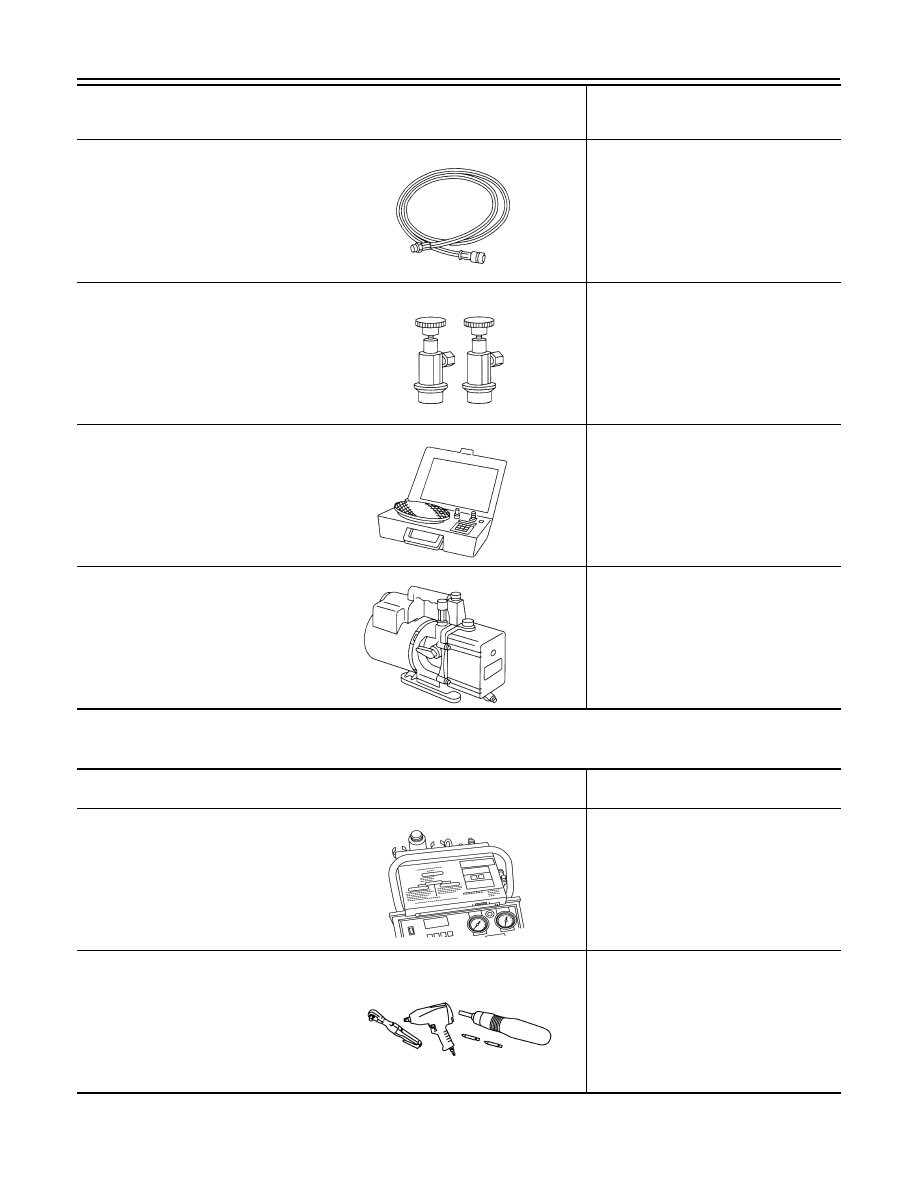

Service hoses:

• High side hose

(J-39500-72B)

• Low side hose

(J-39500-72R)

• Utility hose

(J-39500-72Y)

Hose color:

• Low side hose: Blue with black stripe

• High side hose: Red with black stripe

• Utility hose: Yellow with black stripe or

green with black stripe

Hose fitting to gauge:

• 1/2”-16 ACME

Service couplers

• High side coupler

(J-39500-20A)

• Low side coupler

(J-39500-24A)

Hose fitting to service hose:

• M14 x 1.5 fitting is optional or perma-

nently attached.

—

(J-39699)

Refrigerant weight scale

For measuring of refrigerant

Fitting size-Thread size

• 1/2”-16 ACME

—

(J-39649)

Vacuum pump

(Including the isolator valve)

Capacity:

• Air displacement: 4 CFM

• Micron rating: 20 microns

• Oil capacity: 482 g (17 oz)

Fitting size-Thread size

• 1/2”-16 ACME

Tool number

(TechMate No.)

Tool name

Description

S-NT201

S-NT202

S-NT200

S-NT203

(TechMate No.)

Tool name

Description

(J-41810-NI)

Refrigerant identifier equipment (R-

134a)

For checking refrigerant purity and sys-

tem contamination

Power tool

Loosening nuts, screws and bolts

RJIA0197E

PIIB1407E