Nissan Frontier. Manual - part 752

CAMSHAFT

EM-197

< REMOVAL AND INSTALLATION >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

• Measure the outer diameter at 1/2 height of valve lifter with

micrometer since valve lifter is in barrel shape.

VALVE LIFTER HOLE DIAMETER

• Measure the inner diameter of valve lifter hole of cylinder head with

inside micrometer.

VALVE LIFTER CLEARANCE

• (Valve lifter clearance) = (Valve lifter hole diameter) – (Valve lifter outer diameter), Refer to

.

• If the calculated value is out of the standard, referring to each standard of valve lifter outer diameter and

valve lifter hole diameter, replace either or both valve lifter and cylinder head.

INSTALLATION

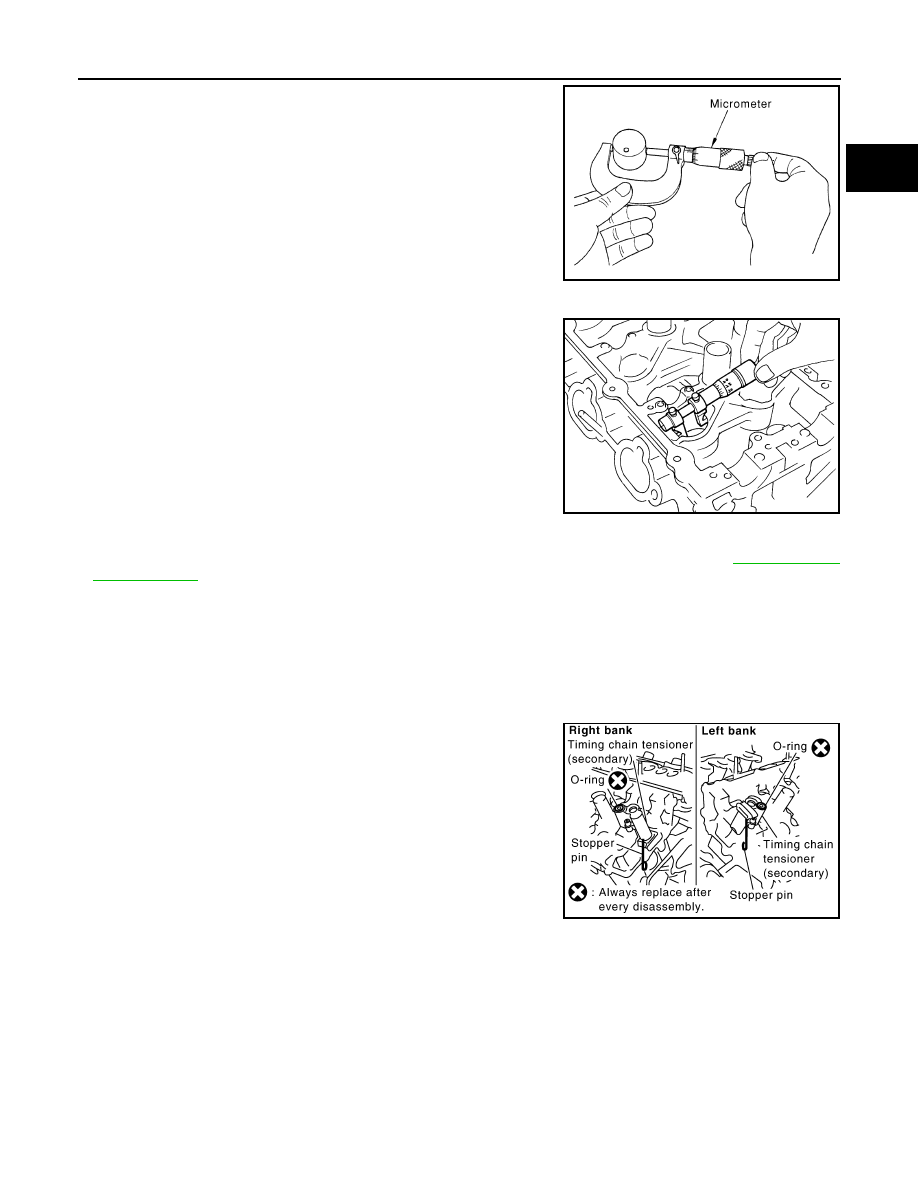

1. Install timing chain tensioners (secondary) on both sides of cyl-

inder head.

• Install timing chain tensioner with its stopper pin attached.

• Install timing chain tensioner with sliding part facing downward

on right-side cylinder head, and with sliding part facing upward

on left-side cylinder head.

• Install new O-rings as shown.

CAUTION:

Do not reuse O-rings.

2. Install valve lifters.

• Install it in the original position.

3. Install camshafts.

Standard (Intake and exhaust)

: 33.977 - 33.987 mm (1.3377 - 1.3381 in)

JEM798G

Standard (Intake and exhaust)

: 34.000 - 34.016 mm (1.3386 - 1.3392 in)

SEM867E

Standard (Intake and exhaust)

: 0.013 - 0.039 mm (0.0005 - 0.0015 in)

PBIC2111E