Nissan Frontier. Manual - part 746

FRONT TIMING CHAIN CASE

EM-173

< REMOVAL AND INSTALLATION >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

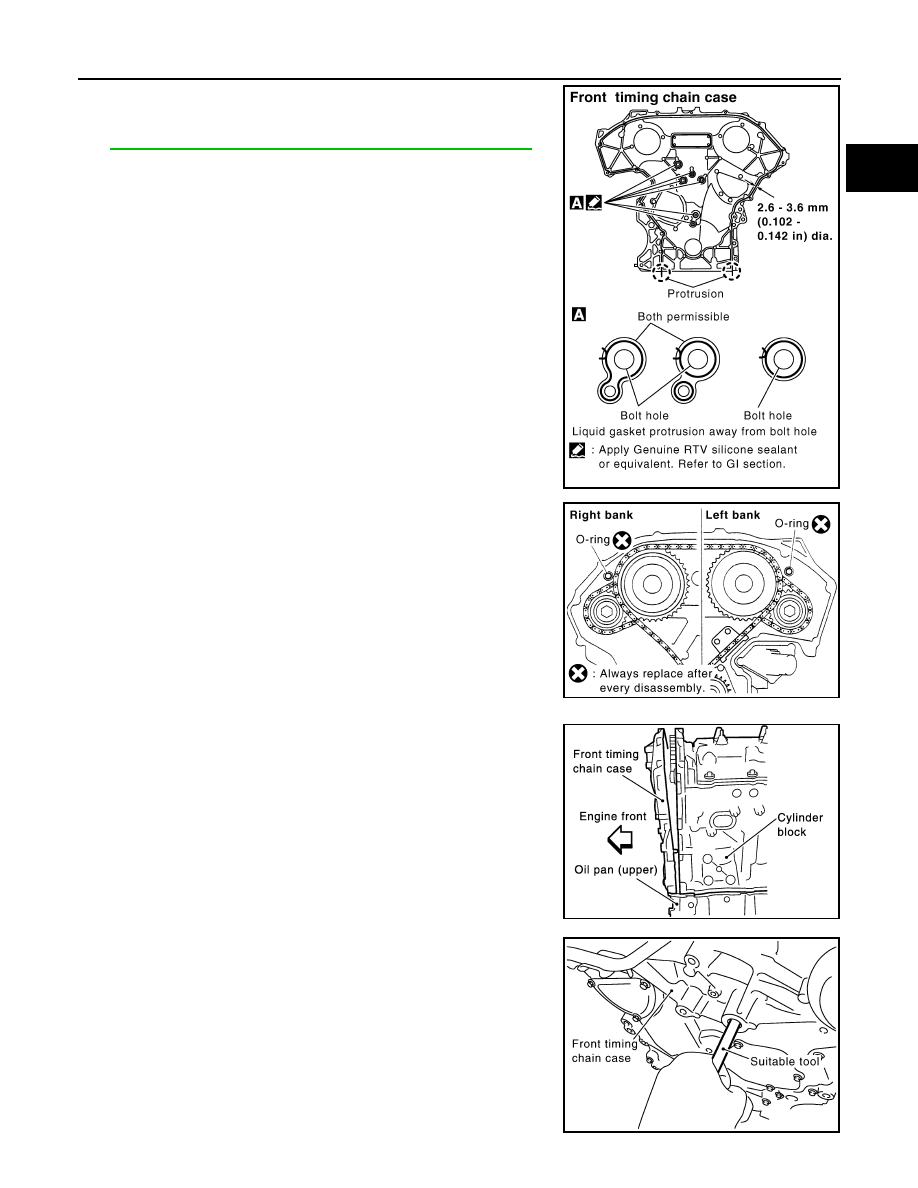

a. Apply a continuous bead of liquid gasket using Tool to front tim-

ing chain case back side as shown.

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-21, "Recommended Chemical Products and Sealants"

.

b. Install new O-rings on rear timing chain case.

CAUTION:

Do not reuse O-rings.

c. Assemble front timing chain case as follows:

i.

Fit lower end of front timing chain case tightly onto top face of oil

pan (upper). From the fitting point, make entire front timing chain

case contact rear timing chain case completely.

ii.

Since front timing chain case is offset for difference of bolt holes,

tighten bolts temporarily while holding front timing chain case

from front and top as shown.

iii. Same as the previous step, insert dowel pin while holding front

timing chain case from front and top completely.

Tool number

: WS39930000 ( — )

PBIC2913E

PBIC2548E

PBIC1100E

PBIC2915E