Nissan Frontier. Manual - part 728

HOW TO SELECT PISTON AND BEARING

EM-101

< UNIT DISASSEMBLY AND ASSEMBLY >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

HOW TO SELECT PISTON AND BEARING

How to Select Piston and Bearing

INFOID:0000000009478081

DESCRIPTION

*For the service parts, the grade for fitting cannot be selected between piston pin and connecting rod. (Only grade “0” is available.) The

information at the shipment from the plant is described as a reference.

• The identification grade stamped on each part is the grade for the dimension measured in new condition.

This grade cannot apply to reused parts.

• For reused or repaired parts, measure the dimension accurately. Determine the grade by comparing the

measurement with the values of each selection table.

• For details of the measurement method of each part, the reuse standards and the selection method of the

selective fitting parts, follow the applicable procedures.

HOW TO SELECT PISTON

When New Cylinder Block Is Used

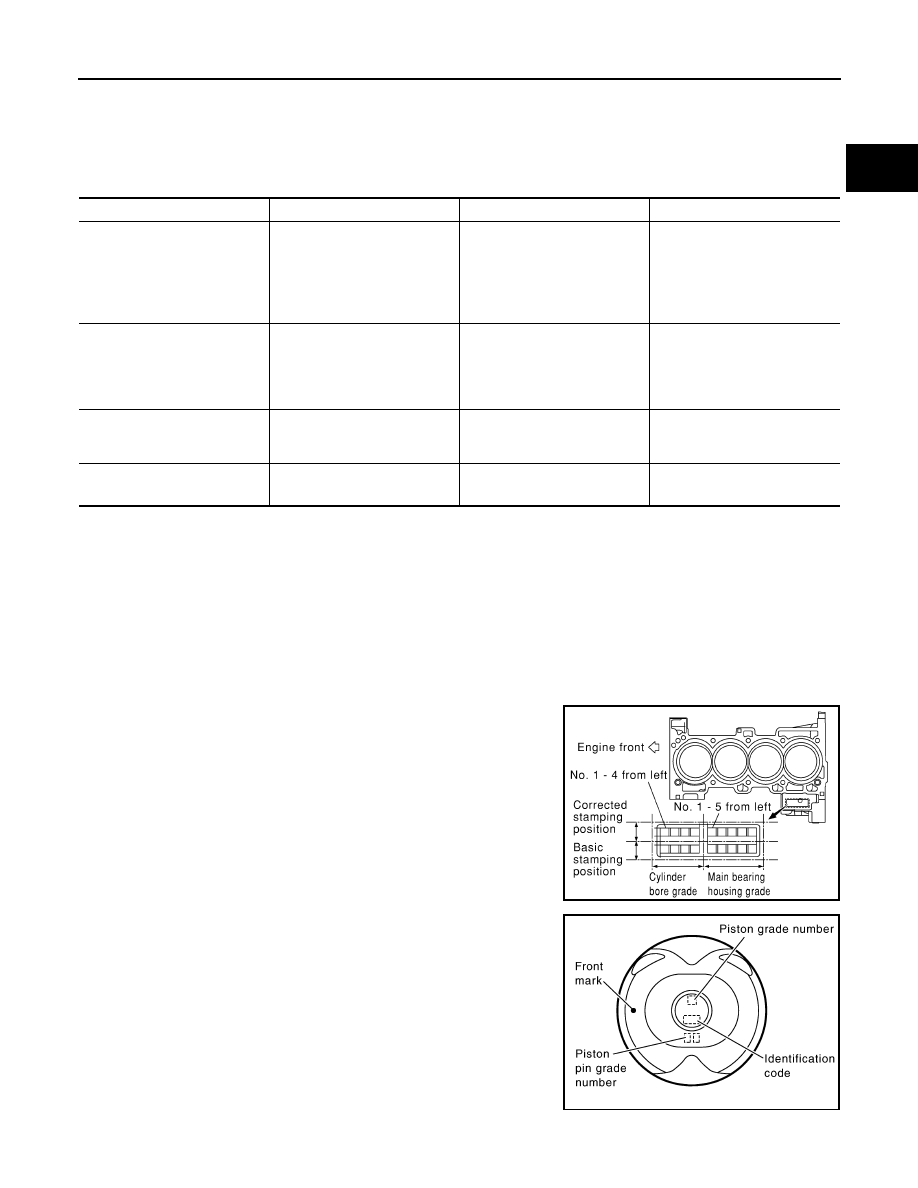

• Check the cylinder bore grade on rear-left side of cylinder block,

and select piston of the same grade.

• If there is a corrected stamp mark on cylinder block, use it as a cor-

rect reference.

When Cylinder Block Is Reused

Selection points

Selection parts

Selection items

Selection methods

Between cylinder block and

crankshaft

Main bearing

Main bearing grade (bearing

thickness)

Determined by match of cylin-

der block bearing housing

grade (inner diameter of hous-

ing) and crankshaft journal

grade (outer diameter of jour-

nal)

Between crankshaft and con-

necting rod

Connecting rod bearing

Connecting rod bearing grade

(bearing thickness)

Combining service grades for

connecting rod big end diame-

ter and crankshaft pin outer di-

ameter determine connecting

rod bearing selection.

Between cylinder block and pis-

ton

Piston and piston pin assembly

(piston is available together with

piston pin as an assembly.)

Piston grade (piston skirt diam-

eter)

Piston grade = cylinder bore

grade (inner diameter of bore)

Between piston and connecting

rod

*

—

—

—

SBIA0283E

PBIC3019E