Nissan Frontier. Manual - part 712

ROCKER COVER

EM-37

< REMOVAL AND INSTALLATION >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

ROCKER COVER

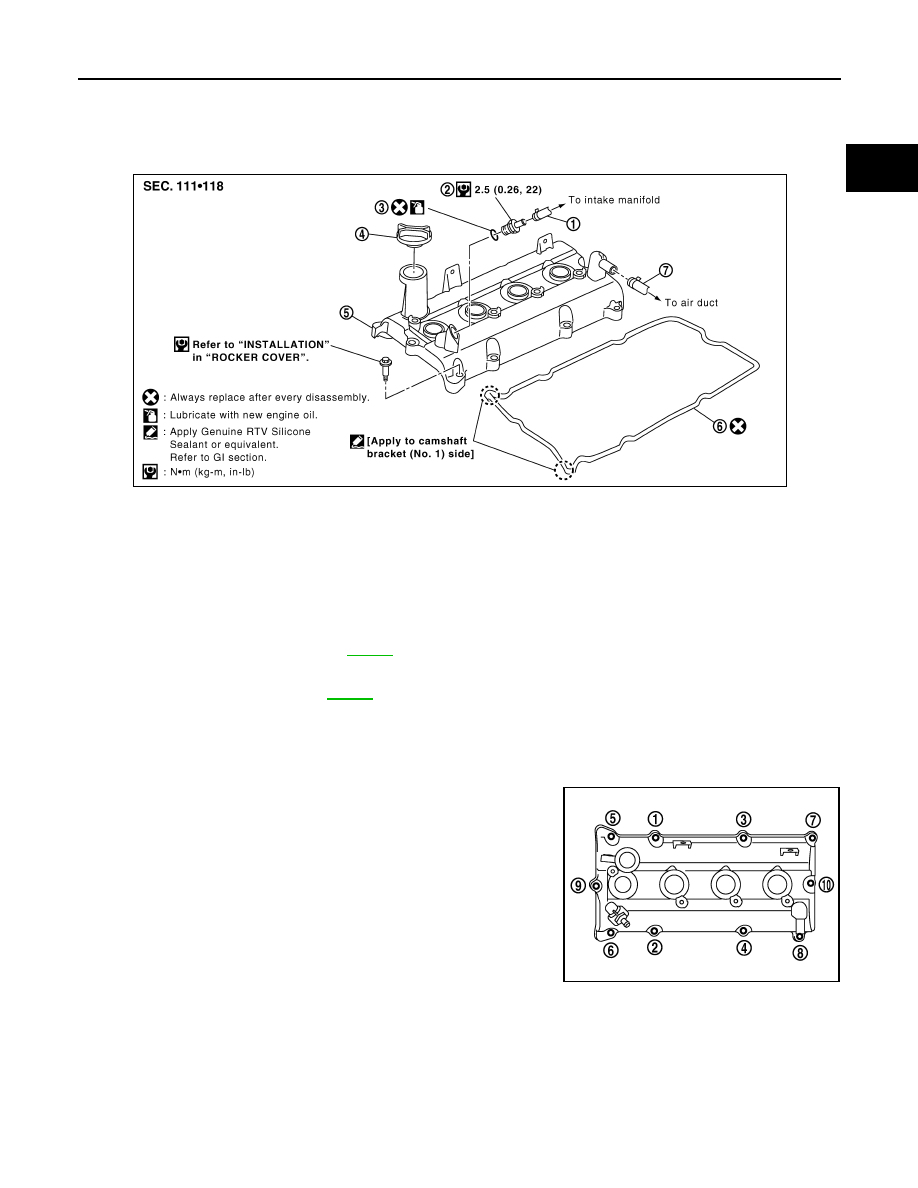

Exploded View

INFOID:0000000009478059

Removal and Installation

INFOID:0000000009478060

REMOVAL

1. Remove intake manifold. Refer to

.

2. Disconnect PCV hose from rocker cover.

3. Remove ignition coils. Refer to

.

4. Remove PCV valve and O-ring from rocker cover, if necessary.

CAUTION:

Do not reuse O-rings.

5. Remove oil filler cap from rocker cover, if necessary.

6. Loosen bolts in reverse order as shown.

7. Remove rocker cover gasket from rocker cover.

8. Use scraper to remove all traces of liquid gasket from cylinder head and camshaft bracket (No. 1).

CAUTION:

Do not scratch or damage the mating surface when cleaning off old liquid gasket.

INSTALLATION

1.

PCV hose

2.

PCV valve

3.

O-ring

4.

Oil filler cap

5.

Rocker cover

6.

Rocker cover gasket

7.

PCV hose

WBIA0650E

PBIC3003E