Nissan Frontier. Manual - part 711

OIL PAN

EM-33

< REMOVAL AND INSTALLATION >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

OIL PAN

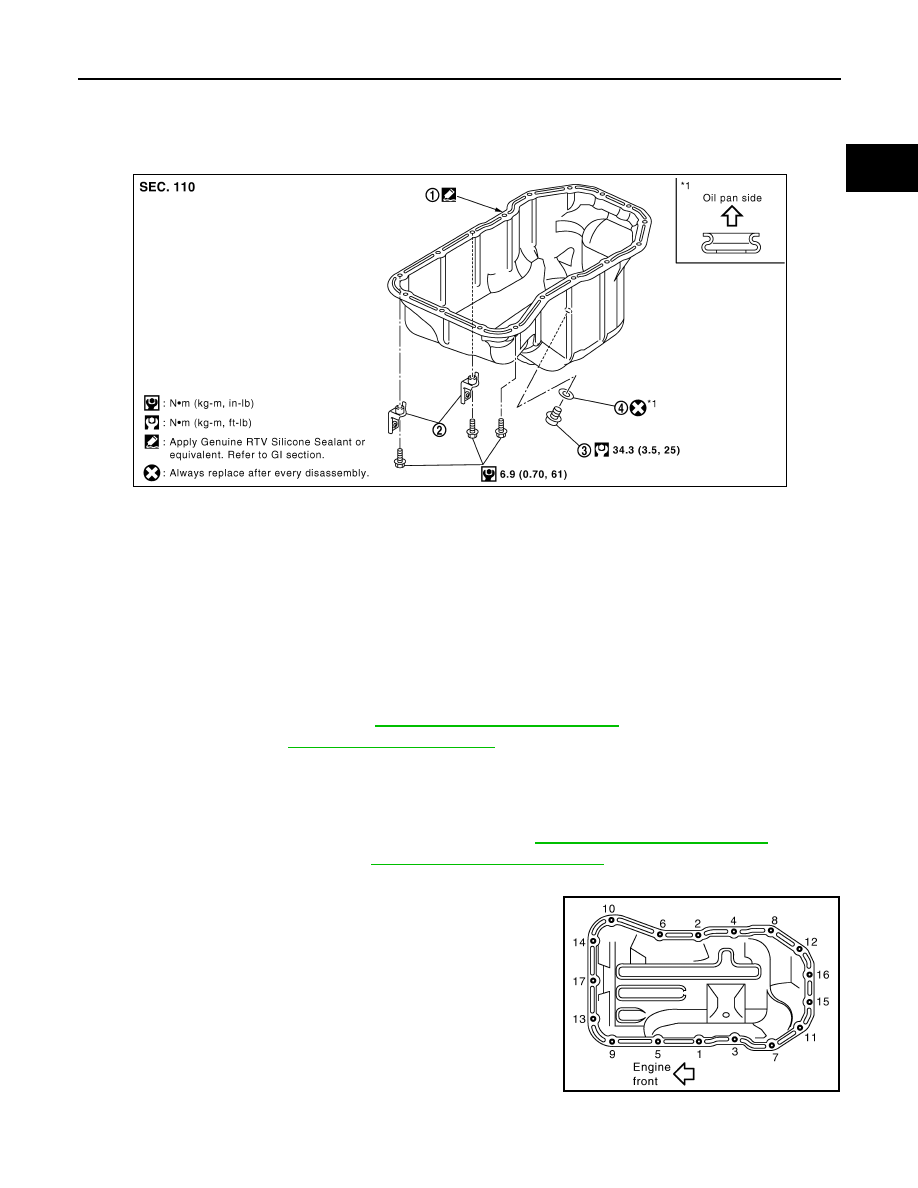

Exploded View

INFOID:0000000009478055

Removal and Installation

INFOID:0000000009478056

REMOVAL

WARNING:

To avoid the danger of being scalded, do not drain engine oil when engine is hot.

NOTE:

When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spill-

ing.

1. Remove engine under cover. Refer to

EXT-15, "Removal and Installation"

.

2. Drain engine oil. Refer to

CAUTION:

• Perform this step when the engine is cold.

• Do not spill engine oil on drive belt.

3. Remove 3rd crossmember assembly.

4. Remove lower joint shaft pinch bolt at steering gear. Refer to

ST-12, "Removal and Installation"

.

5. Remove steering gear bolts. Refer to

ST-15, "Removal and Installation"

.

6. Remove oil pan with the following procedure:

a. Loosen bolts in reverse order as shown with power tool.

Remove A/T fluid cooler tube bracket (A/T models).

1.

Oil pan

2.

A/T fluid cooler tube bracket (A/T models)

3.

Drain plug

4.

Drain plug washer

PBIC2992E

PBIC2993E