Nissan Frontier. Manual - part 699

REFRIGERANT PRESSURE SENSOR

EC-1367

< DTC/CIRCUIT DIAGNOSIS >

[VQ40DE FOR MEXICO]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

OK or NG

OK

>> GO TO 3.

NG

>> Repair or replace ground connections.

3.

CHECK REFRIGERANT PRESSURE SENSOR POWER SUPPLY CIRCUIT

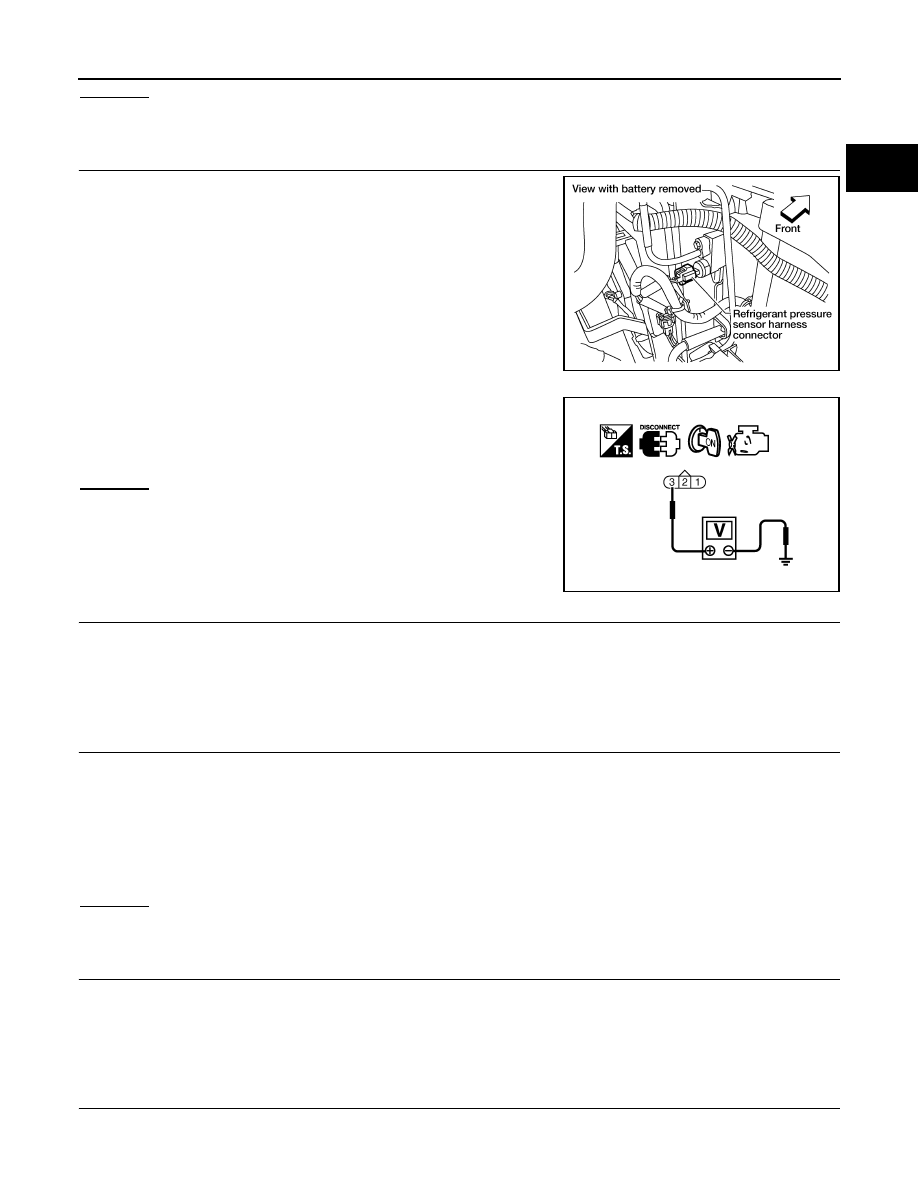

1. Disconnect refrigerant pressure sensor harness connector.

2. Turn ignition switch ON.

3. Check voltage between refrigerant pressure sensor terminal 3

and ground with CONSULT or tester.

OK or NG

OK

>> GO TO 5.

NG

>> GO TO 4.

4.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E5, F14

• Harness for open or short between ECM and refrigerant pressure sensor

>> Repair harness or connectors.

5.

CHECK REFRIGERANT PRESSURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between refrigerant pressure sensor terminal 1 and ECM terminal 67.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK

>> GO TO 7.

NG

>> GO TO 6.

6.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E5, F14

• Harness for open or short between ECM and refrigerant pressure sensor

>> Repair open circuit or short to ground or short to power in harness or connectors.

7.

CHECK REFRIGERANT PRESSURE SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminal 70 and refrigerant pressure sensor terminal 2.

Refer to Wiring Diagram.

BBIA0564E

Voltage: Approximately 5V

PBIB1872E

Continuity should exist.