Nissan Frontier. Manual - part 637

P0117, P0118 ECT SENSOR

EC-1119

< DTC/CIRCUIT DIAGNOSIS >

[VQ40DE FOR MEXICO]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

DTC Confirmation Procedure

INFOID:0000000009481768

1. If DTC Confirmation Procedure has been previously conducted, always perform the following before con-

ducting the next step.

a. Turn ignition switch OFF and wait at least 10 seconds.

b. Turn ignition switch ON.

c. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON and wait at least 5 seconds.

3. Check DTC.

4. If DTC is detected, go to

EC-1119, "Diagnosis Procedure"

Diagnosis Procedure

INFOID:0000000009481769

1.

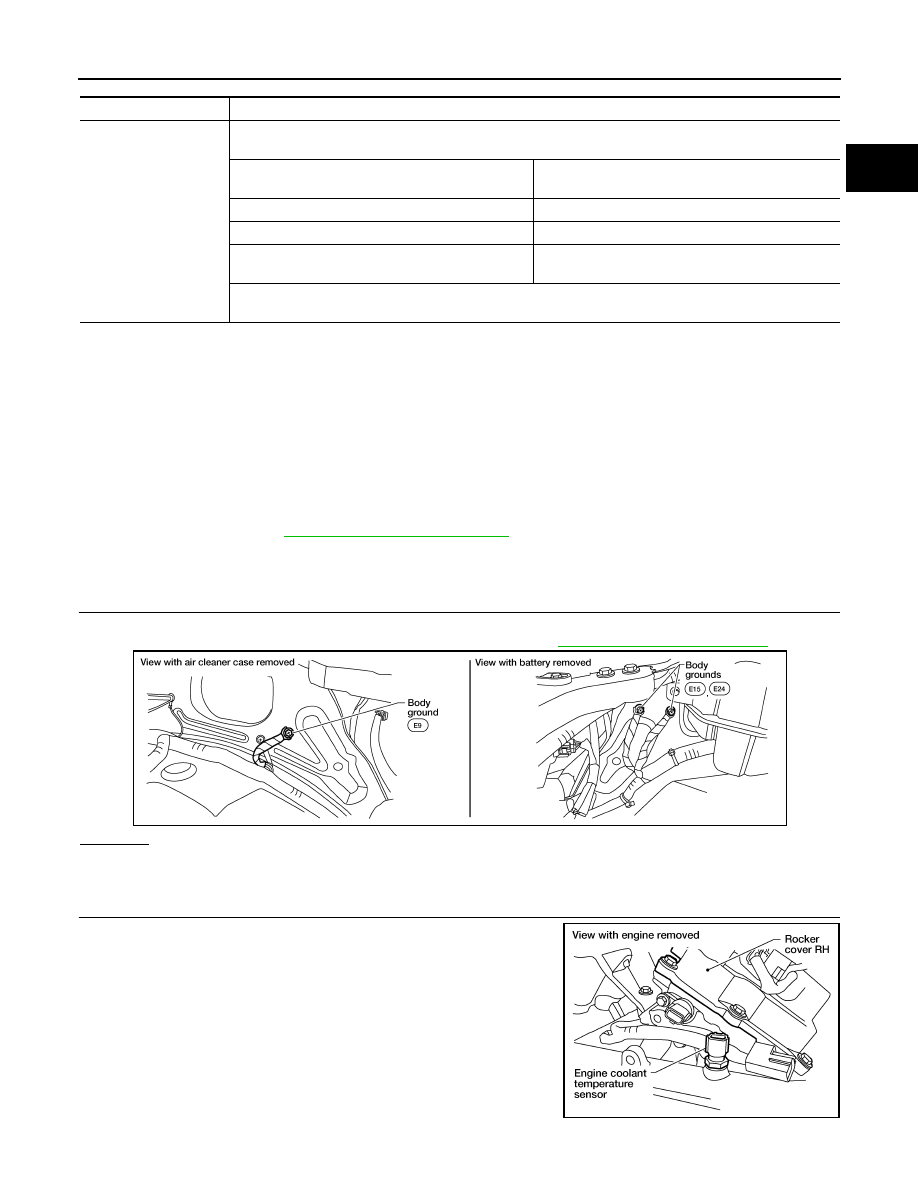

CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body. Refer to

.

OK or NG

OK

>> GO TO 2.

NG

>> Repair or replace ground connections.

2.

CHECK ECT SENSOR POWER SUPPLY CIRCUIT

1. Disconnect engine coolant temperature (ECT) sensor harness

connector.

2. Turn ignition switch ON.

Detected items

Engine operating condition in fail-safe mode

Engine coolant temper-

ature sensor circuit

Engine coolant temperature will be determined by ECM based on the following condition.

CONSULT displays the engine coolant temperature decided by ECM.

Condition

Engine coolant temperature decided

(CONSULT display)

Just as ignition switch is turned ON or START

40

°C (104°F)

Approx. 4 minutes or more after engine starting

80

°C (176°F)

Except as shown above

40 - 80

°C (104 - 176°F)

(Depends on the time)

When the fail-safe system for engine coolant temperature sensor is activated, the cooling fan operates while

engine is running.

BBIA0539E

BBIA0542E