Nissan Frontier. Manual - part 403

P0117, P0118 ECT SENSOR

EC-183

< DTC/CIRCUIT DIAGNOSIS >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECT sensor terminal 2 and ECM terminal 52.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK

>> GO TO 4.

NG

>> Repair open circuit, short to ground or short to power in harness or connectors.

4.

CHECK ENGINE COOLANT TEMPERATURE SENSOR

EC-183, "Component Inspection"

OK or NG

OK

>> GO TO 5.

NG

>> Replace engine coolant temperature sensor. Refer to

5.

CHECK INTERMITTENT INCIDENT

GI-42, "Intermittent Incident"

.

>> INSPECTION END

Component Inspection

INFOID:0000000009480832

ENGINE COOLANT TEMPERATURE SENSOR

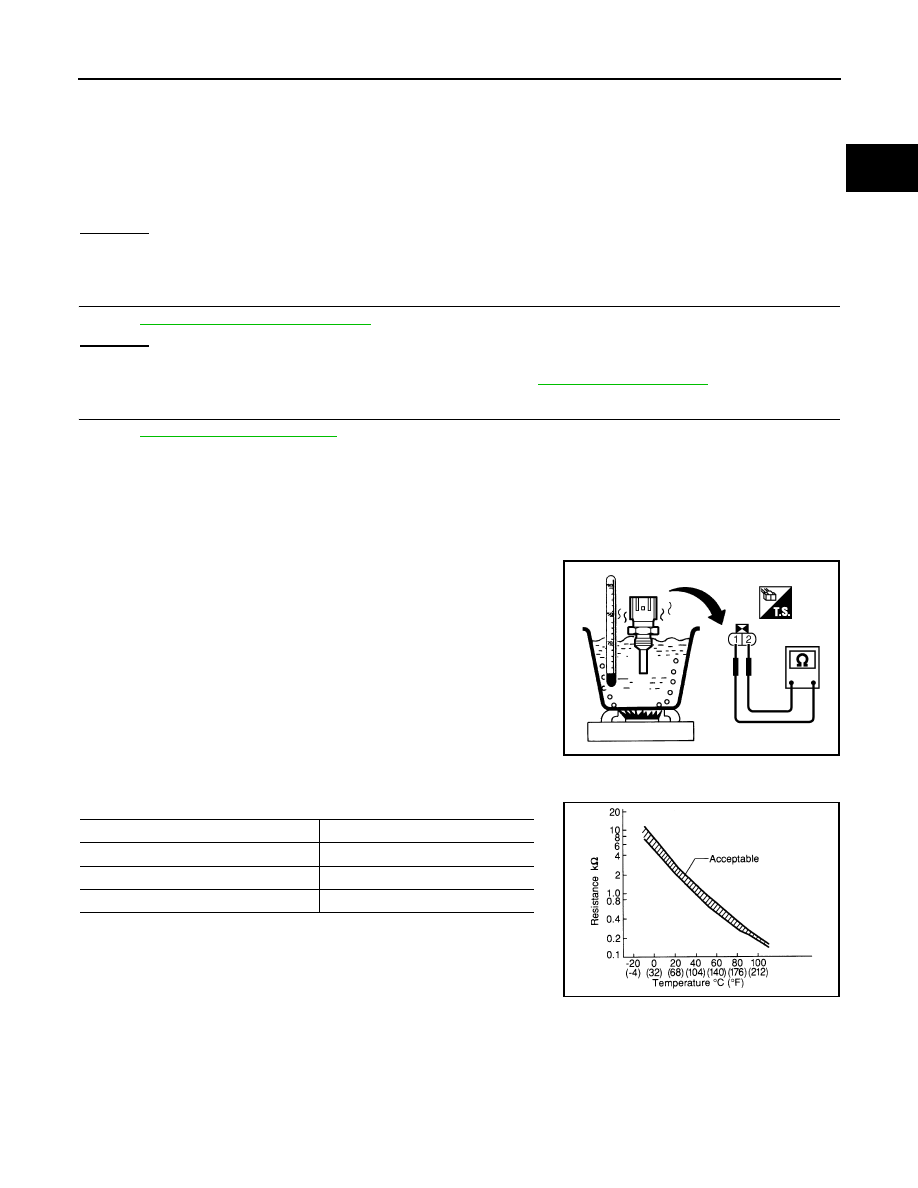

1. Check resistance between engine coolant temperature sensor

terminals 1 and 2 as shown in the figure.

<Reference data>

2. If NG, replace engine coolant temperature sensor.

Continuity should exist.

PBIB2005E

Engine coolant temperature [

°C (°F)]

Resistance (k

Ω)

20 (68)

2.1 - 2.9

50 (122)

0.68 - 1.00

90 (194)

0.236 - 0.260

SEF012P