Nissan Frontier. Manual - part 334

DLN-238

< UNIT DISASSEMBLY AND ASSEMBLY >

[C200]

REAR FINAL DRIVE

13. Remove the Tool from the gear carrier and disassemble to

retrieve the drive pinion bearings.

ASSEMBLY

Drive Pinion Assembly

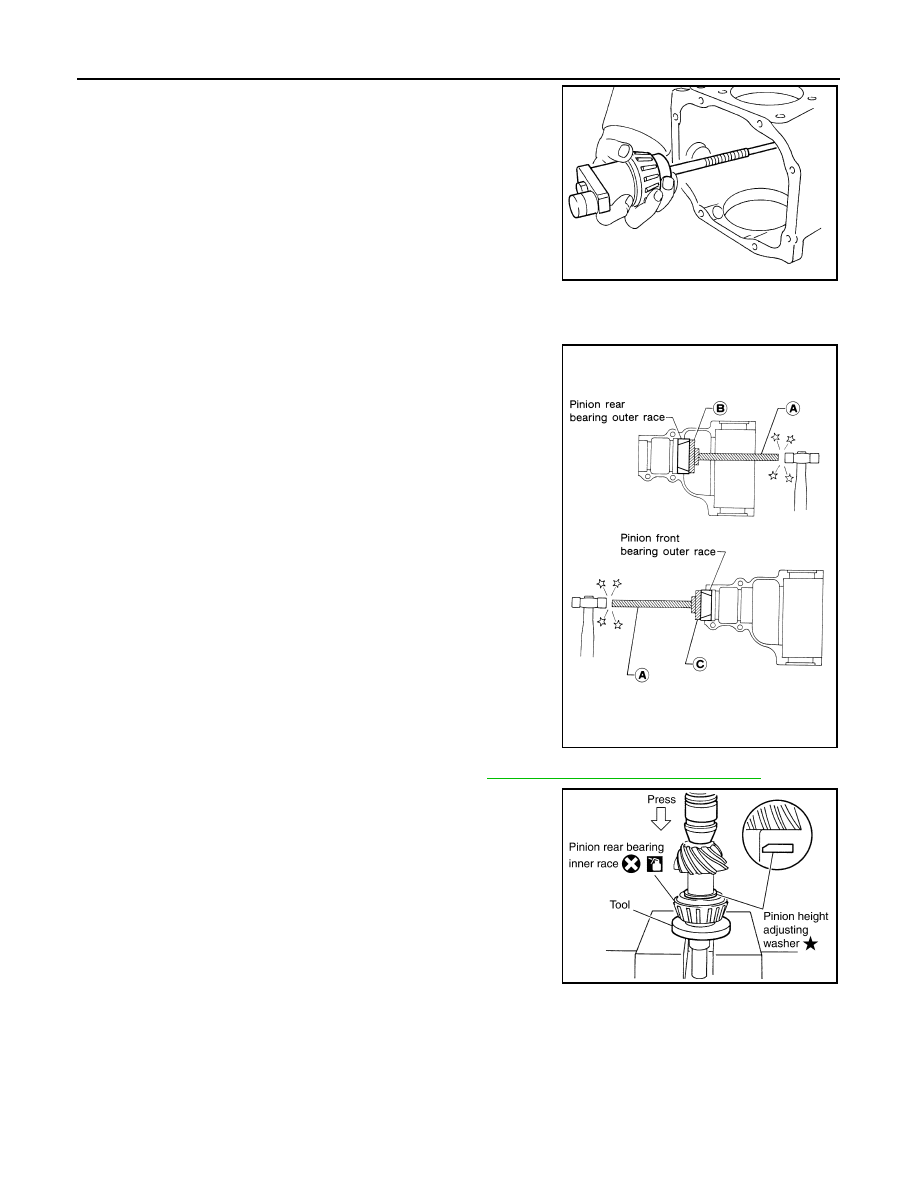

1. Install the new drive pinion front and rear bearing outer races

using Tools.

CAUTION:

• First tap the drive pinion bearing outer race until it

becomes flush with the gear carrier.

• Do not reuse drive pinion front and rear bearing outer

race.

2. Select a drive pinion height adjusting washer. Refer to

DLN-225, "Disassembly and Assembly"

.

3. Install the selected drive pinion height adjusting washer to the

drive pinion. Press the new drive pinion rear bearing inner race

to it using Tool.

CAUTION:

• Install the drive pinion height adjusting washer in the

proper direction as shown.

• Do not reuse drive pinion rear bearing inner race.

Tool number

:

—

(J-34309)

SPD205A

Tool number

(A): ST30611000 (J-25742-1)

(B): ST30621000 (J-25742-5)

(C): ST30613000 (J-25742-3)

SPD679

Tool number

: ST30901000 (J-26010-01)

SDIA0048E