Nissan Frontier. Manual - part 325

DLN-202

< UNIT DISASSEMBLY AND ASSEMBLY >

[FRONT FINAL DRIVE: R180A]

FRONT FINAL DRIVE

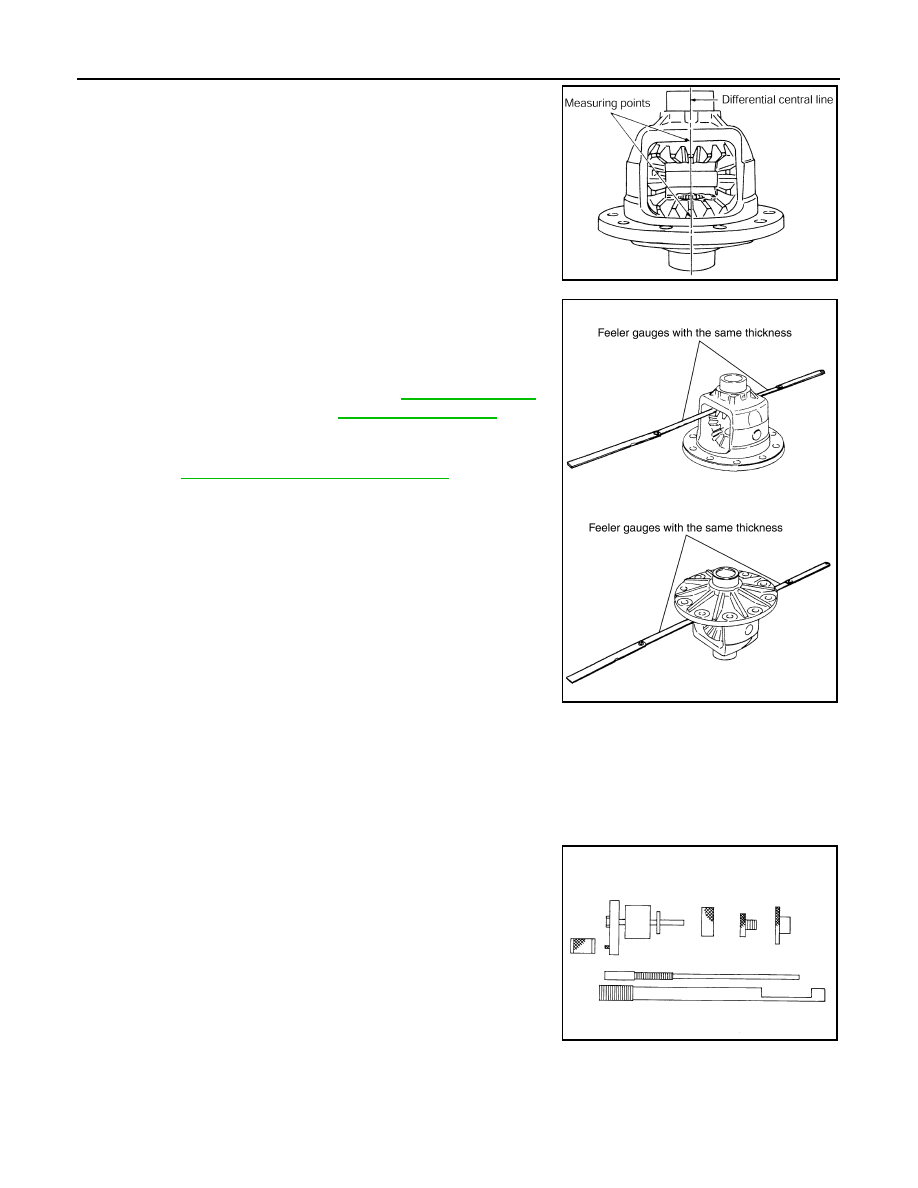

1. Place the differential case straight up so that the side gear to be

measured is upward.

2. Using feeler gauges, measure the clearance between the side

gear back and differential case at three different points, while

rotating the side gear. Average the three readings to calculate

the clearance. (Measure the clearance of the other side as well.)

• If the side gear back clearance is outside of the specification,

use a thicker or thinner side gear thrust washer to adjust.

Refer to

DLN-212, "Inspection and Adjustment"

CAUTION:

• Insert feeler gauges with the same thickness on both

sides to prevent side gear from tilting.

• Each gear should rotate smoothly without excessive

resistance during differential motion.

• Select a side gear thrust washer for right and left individually.

NOTE:

Side gear back clearance is clearance between side gear and differential case for adjusting side gear

backlash.

Drive Pinion Height

1. Make sure all parts are clean and that the bearings are well lubricated.

2. Assemble the drive pinion bearings onto the Tool.

PDIA0460E

Side gear back clearance: Refer to

If the side gear back clearance is greater than

specification:

Use a thicker side gear thrust washer.

If the side gear back clearance is less than spec-

ification:

Use a thinner side gear thrust washer.

PDIA0576E

Tool number

:

—

(J-34309)

SPD769