Nissan Frontier. Manual - part 324

DLN-198

< UNIT DISASSEMBLY AND ASSEMBLY >

[FRONT FINAL DRIVE: R180A]

FRONT FINAL DRIVE

Differential Assembly

1. Remove differential side shaft assembly. Refer to

DLN-189, "Removal and Installation"

.

2. Remove side seal from gear carrier using suitable tool.

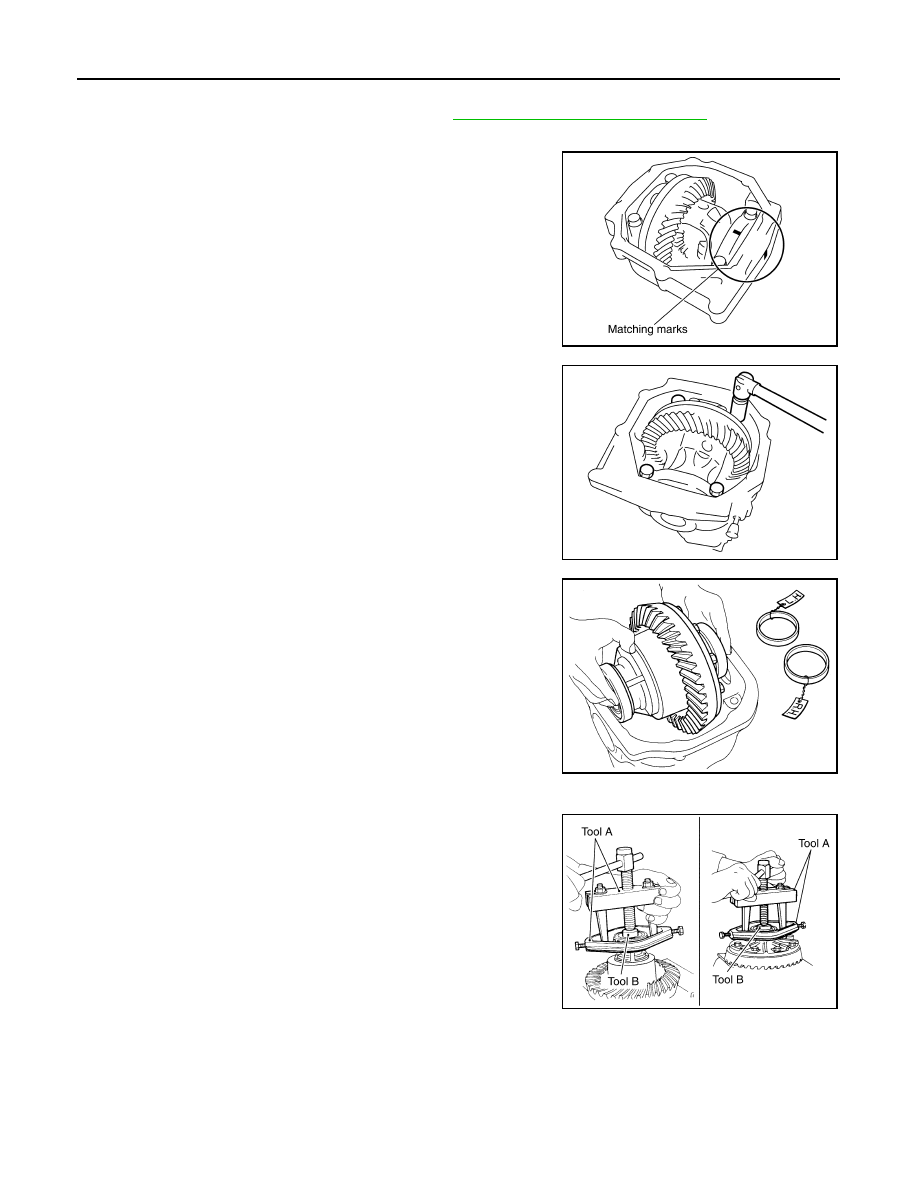

3. For proper reinstallation, paint matching marks on one side of

the side bearing cap and gear carrier.

CAUTION:

• For matching marks, use paint. Do not damage side bear-

ing cap or gear carrier.

• Side bearing caps are line-board during manufacture. The

matching marks are used to reinstall them in their original

positions.

4. Remove the side bearing caps.

5. Lift the differential case assembly out of the gear carrier.

CAUTION:

• Keep side bearing outer races together with side bearing

inner races. Do not mix them up.

• Keep side bearing adjusting washers together with side

bearings.

6. Remove housing spacer.

7. Remove side bearing inner race using Tools as shown.

CAUTION:

• Do not remove side bearing inner race unless it is being

replaced.

• Place copper plates between the vise and the side bearing

inner race and drive gear to prevent damage.

PDIA0700E

PDIA0701E

SPD919

Tool number

(A): ST33051001 (J-22888-20)

(B): ST33061000 (J-8107-2)

PDIA0827E