Content .. 999 1000 1001 1002 ..

Nissan Frontier. Manual - part 1001

ENGINE MAINTENANCE (VQ40DE)

MA-31

< PERIODIC MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

ENGINE MAINTENANCE (VQ40DE)

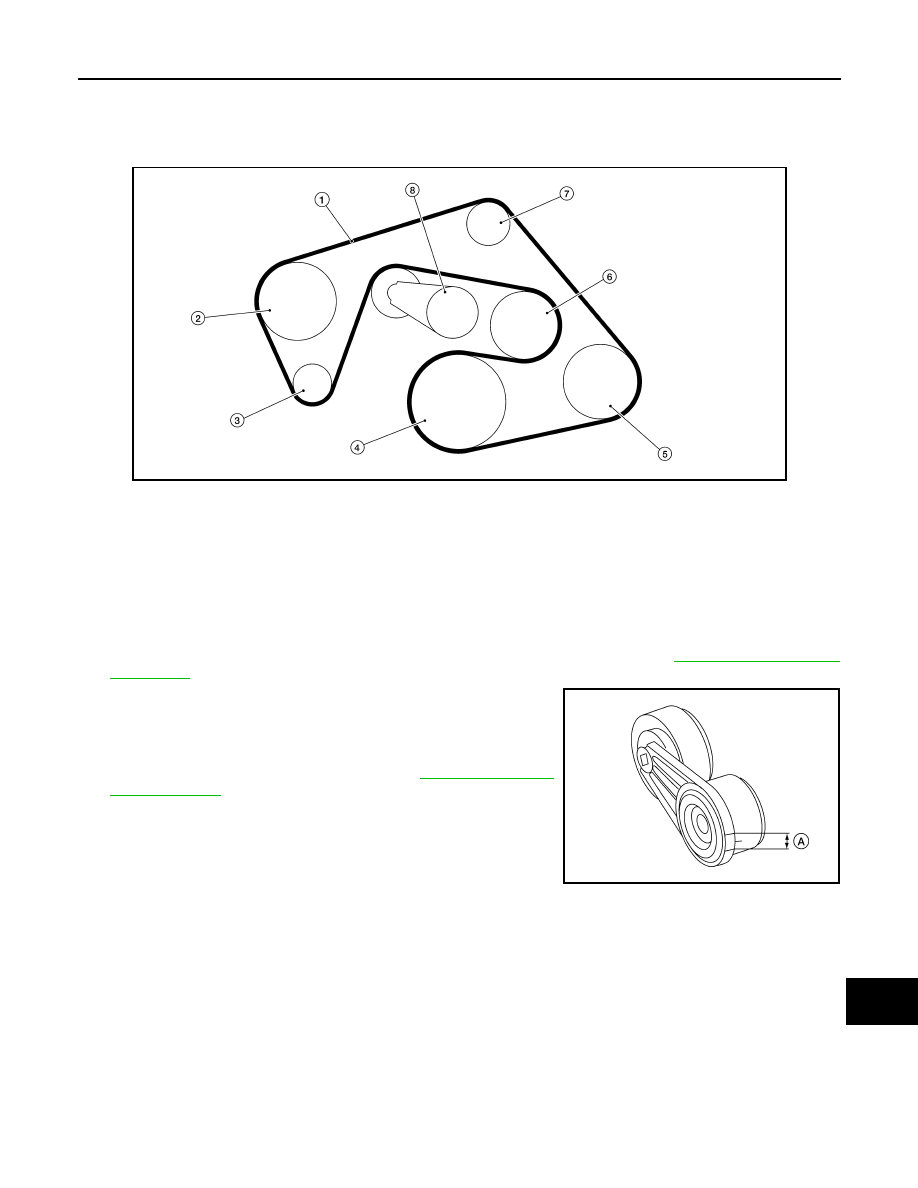

DRIVE BELT

DRIVE BELT : Exploded View

INFOID:0000000009478636

DRIVE BELT : Checking Drive Belts

INFOID:0000000009478637

WARNING:

Be sure to perform when the engine is stopped.

1. Remove air duct and resonator assembly when inspecting drive belt. Refer to

.

2. Make sure that the drive belt tensioner indicator is within the

allowable working range (A) as shown.

3. Visually check entire belt for wear, damage or cracks.

4. If the indicator is out of allowable working range or drive belt is

damaged, replace the drive belt. Refer to

DRIVE BELT : Adjustment

INFOID:0000000009478638

There is no manual drive belt tension adjustment. The drive belt tension is automatically adjusted by the drive

belt auto-tensioner.

ENGINE COOLANT

ENGINE COOLANT : System Inspection

INFOID:0000000009478639

WARNING:

• Do not remove the radiator/reservoir cap when the engine is hot. Serious burns could occur from

high pressure fluid escaping from the radiator or reservoir.

• Wrap a thick cloth around the cap. Slowly push down and turn it a quarter turn to allow built-up pres-

sure to escape. Carefully remove the cap by pushing down and turning it all the way.

LBIA0427E

1.

Drive belt

2.

Power steering oil pump pulley

3.

Generator pulley

4.

Crankshaft pulley

5.

A/C compressor

6.

Cooling fan pulley

7.

Idler pulley

8.

Drive belt tensioner

AWBIA0723ZZ