Content .. 997 998 999 1000 ..

Nissan Frontier. Manual - part 999

ENGINE MAINTENANCE (QR25DE ENGINE)

MA-23

< PERIODIC MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

• Cracks

• Damage

• Loose connections

• Chafing

• Deterioration

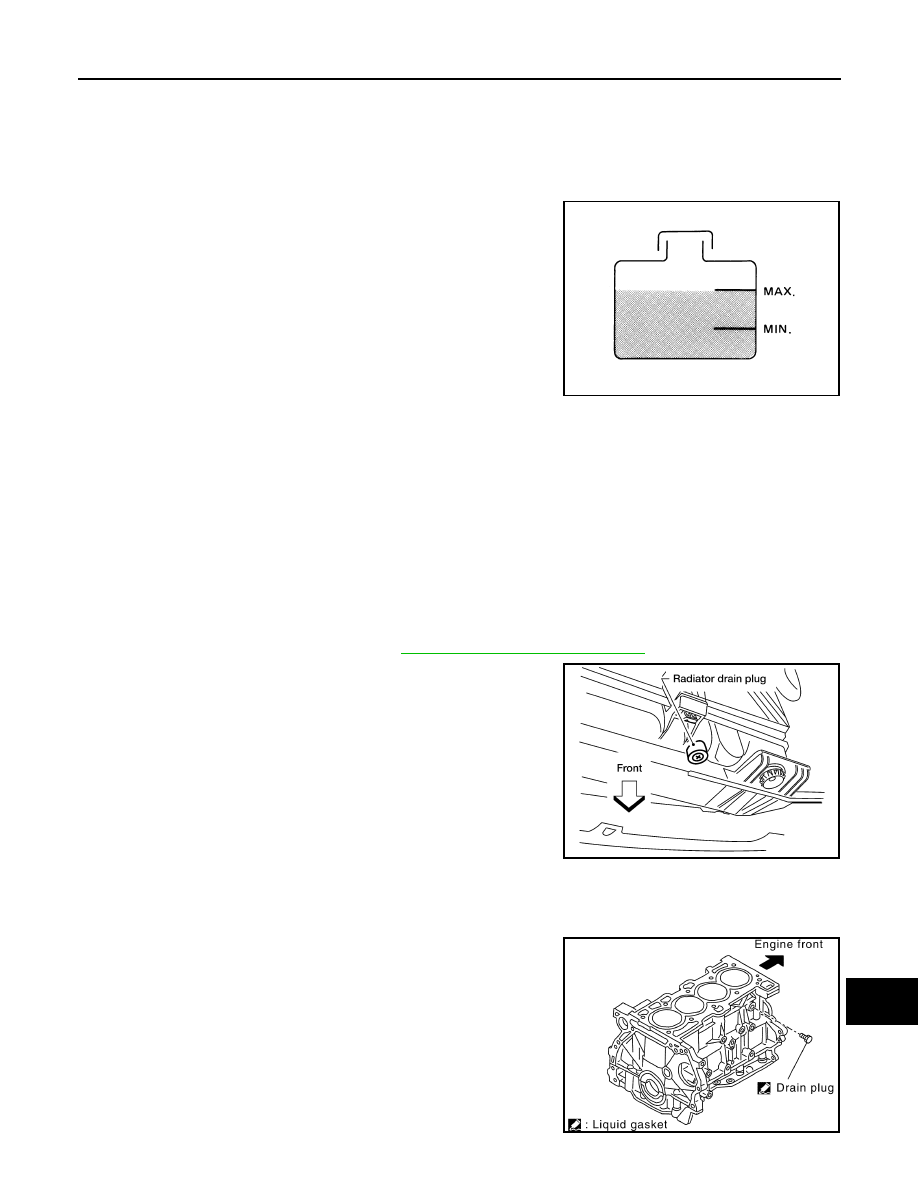

CHECKING RESERVOIR LEVEL

• Check if the engine coolant reservoir tank level is within MIN to

MAX when the engine is cool.

• Adjust engine coolant level as necessary.

ENGINE COOLANT : Changing Engine Coolant

INFOID:0000000009478627

WARNING:

• To avoid being scalded, do not change the coolant when the engine is hot.

• Wrap a thick cloth around the cap to carefully remove the cap. First, turn the cap a quarter of a turn

to release any built-up pressure, then push down and turn the cap all the way to remove it.

• Avoid direct skin contact with used coolant. If skin contact is made, wash thoroughly with soap or

hand cleaner as soon as possible.

• Keep coolant out of the reach of children and pets.

DRAINING ENGINE COOLANT

1. Turn ignition switch ON and set temperature control lever all the way to HOT position or the highest tem-

perature position. Wait 10 seconds and turn ignition switch OFF.

2. Remove the engine under cover. Refer to

EXT-15, "Removal and Installation"

.

3. Open the radiator drain plug at the bottom of the radiator, and

remove the reservoir cap. This is the only step required when

partially draining the cooling system (radiator only).

CAUTION:

• Do not allow the coolant to contact the drive belts.

• Perform this step when engine is cold.

4. Follow this step for heater core removal/replacement only. Disconnect the upper heater hose at the

engine side and apply moderate air pressure [103.46 kPa (15 psi, 1.055 kg/cm

2

) maximum air pressure]

into the hose for 30 seconds to blow the excess coolant out of the heater core.

5. When draining all of the coolant in the system for engine

removal or repair, it is necessary to drain the cylinder block.

Remove the cylinder block drain plug to drain the cylinder block

as shown.

CAUTION:

Do not reuse copper sealing washers.

NOTE:

For Canada, the cylinder block drain plug as shown, is not a cyl-

inder block drain plug but a block heater.

SMA412B

LBIA0063E

KBIA0163E