Nissan Sentra. Manual - part 533

HA-26

< PERIODIC MAINTENANCE >

OIL

Oil Adjusting Procedure for Compressor Replacement

INFOID:0000000009756305

1. Before connecting recovery/recycling equipment to vehicle, check recovery/recycling equipment gauges.

No refrigerant pressure should be displayed. If NG, recover refrigerant from equipment lines.

2. Connect recovery/recycling equipment to vehicle. Confirm refrigerant purity in supply tank using recovery/

recycling equipment and refrigerant identifier. If NG, refer to

HA-4, "Precautions For Refrigerant System

3. Confirm refrigerant purity in vehicle A/C system using recovery/recycling equipment and refrigerant identi-

fier. If NG, refer to

HA-4, "Precautions For Refrigerant System Service"

.

4. Discharge refrigerant into the refrigerant recovery/recycling equipment. Measure oil discharged into the

recovery/recycling equipment.

Replace liquid tank

5 (0.2, 0.2)

Refrigerant leakage is detected

Large amount leakage

30 (1.0, 1.1)

Small amount leakage

—

Oil amount that is recycled together with refrigerant during recycle operation

α

Conditions

Oil amount to be added to A/C system

m (US fl oz, Imp fl oz)

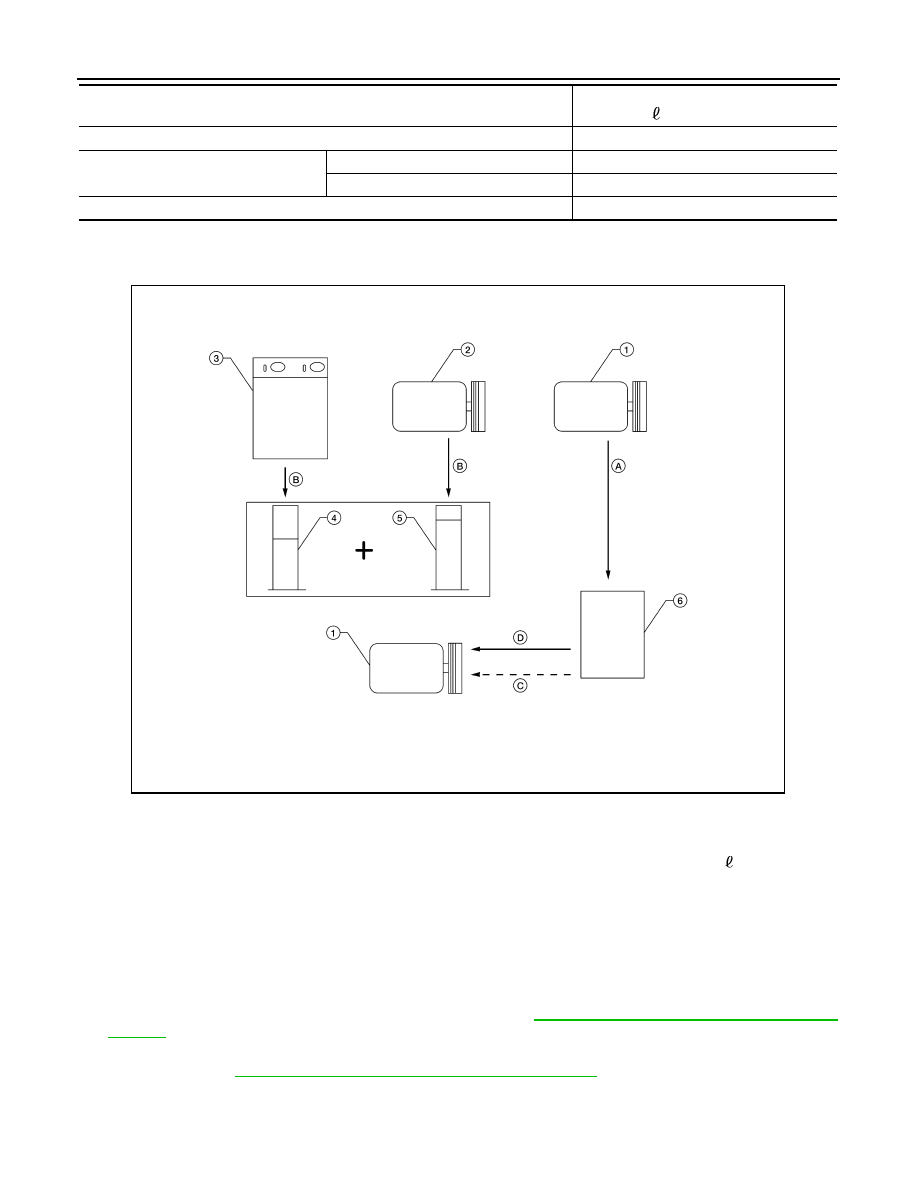

1.

New compressor

2.

Old compressor

3.

Recovery/recycling equipment

4.

Measuring cup X

5.

Measuring cup Y

6.

New oil

A.

Drain oil from the new compressor

into clean container

B.

Record amount of oil recovered

C.

Add an additional 5 m (0.2 US fl oz,

0.2 Imp fl oz) of new oil when replacing

liquid tank

D.

Install new oil equal to recorded

amounts in measuring cups X plus Y

WJIA1716E