Nissan Sentra. Manual - part 415

EC-356

< DTC/CIRCUIT DIAGNOSIS >

[MRA8DE]

P0850 PNP SWITCH

Follow the procedure “With CONSULT” above.

Is 1st trip DTC detected?

YES

>> Proceed to

.

NO

>> INSPECTION END

Component Function Check

INFOID:0000000009758608

1.

CHECK PNP SIGNAL FUNCTION

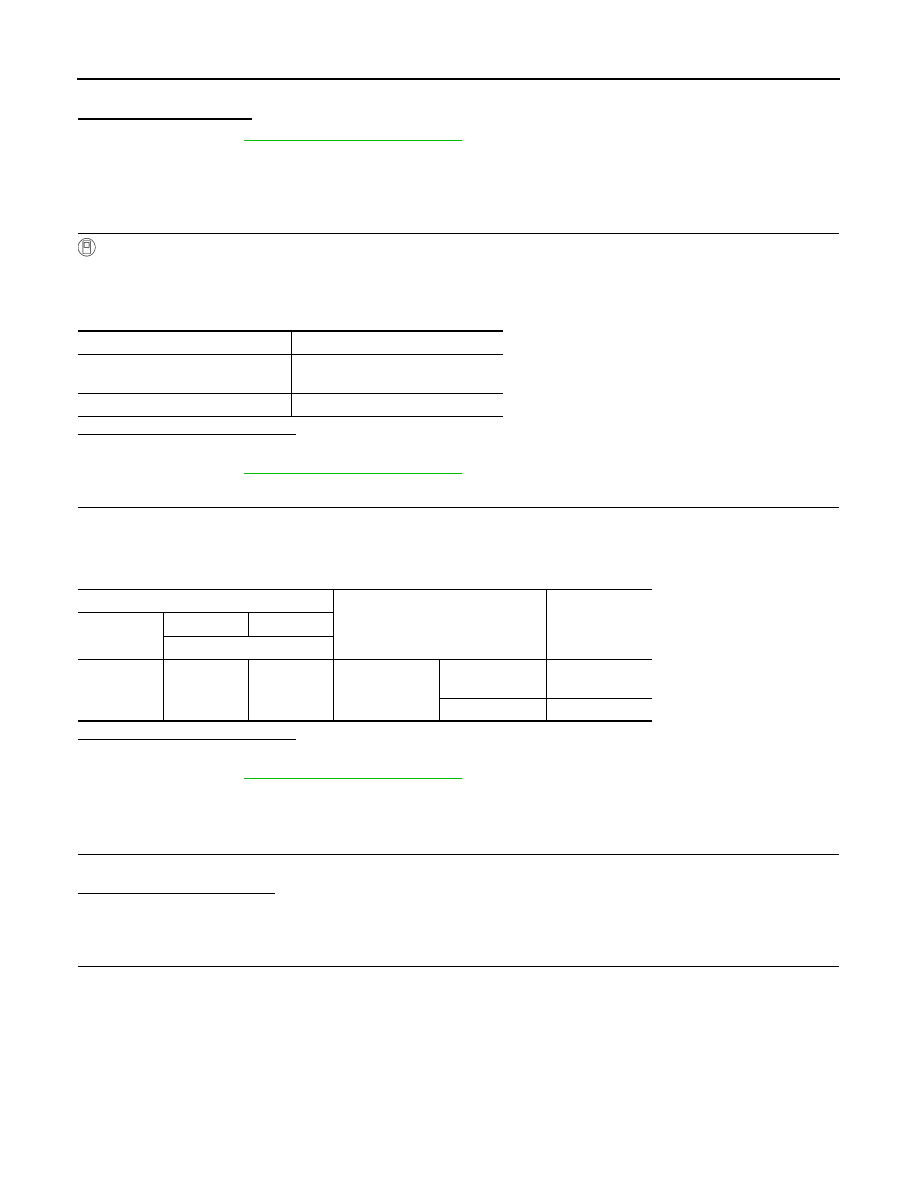

With CONSULT

1. Turn ignition switch ON.

2. Select “P/N POSI SW” in “DATA MONITOR” mode of “ENGINE” using CONSULT. Then check the “P/N

POSI SW” signal as per the following conditions.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Proceed to

.

2.

PERFORM COMPONENT FUNCTION CHECK

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector and ground as per the following conditions.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Proceed to

.

Diagnosis Procedure

INFOID:0000000009758609

1.

INSPECTION START

Check which type of transmission the vehicle is equipped with.

Which type of transmission?

CVT models>>GO TO 2.

M/T models>>GO TO 6.

2.

CHECK TRANSMISSION RANGE SWITCH POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect transmission range switch harness connector.

3. Turn ignition switch ON.

4. Check the voltage between transmission range switch harness connector and ground.

Selector lever position

Indication

N or P position (CVT)

Neutral position (M/T)

ON

Except above position

OFF

ECM

Condition

Voltage

(Approx.)

Connector

+

−

Terminal

E16

117

128

Selector lever

• P or N (CVT)

• Neutral (M/T)

Battery voltage

Except above

0 V