Nissan Sentra. Manual - part 392

EC-264

< DTC/CIRCUIT DIAGNOSIS >

[MRA8DE]

P0197, P0198 EOT SENSOR

P0197, P0198 EOT SENSOR

DTC Logic

INFOID:0000000009758513

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and wait at least 5 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Proceed to

.

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000009758514

1.

CHECK ENGINE OIL TEMPERATURE SENSOR POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect engine oil temperature (EOT) sensor harness connector.

3. Turn ignition switch ON.

4. Check the voltage between EOT sensor harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> GO TO 2.

2.

CHECK ENGINE OIL TEMPERATURE SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between EOT sensor harness connector and ECM harness connector.

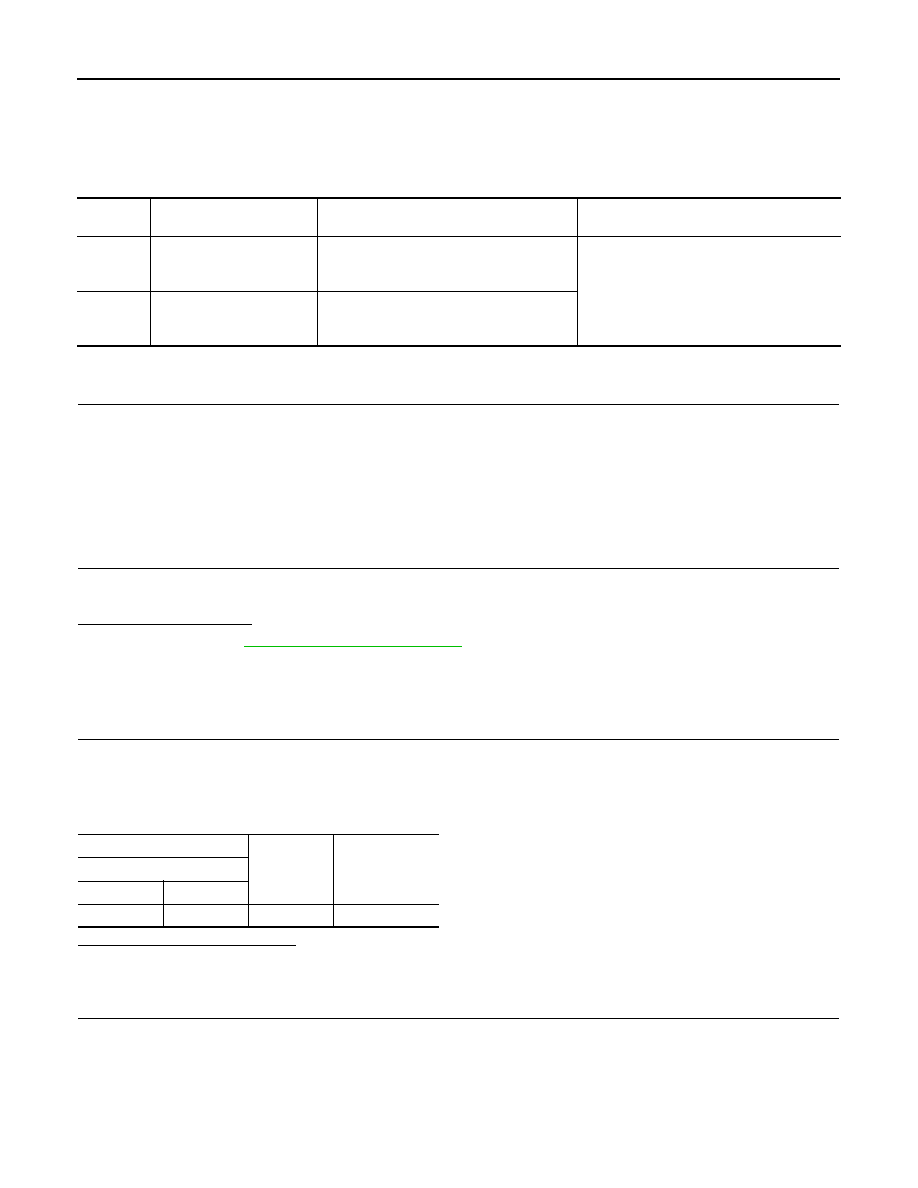

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0197

EOT SEN/CIRC

(Engine oil temperature

sensor circuit low)

An excessively low voltage from the engine

oil temperature sensor is sent to ECM.

• Harness or connectors

(EOT sensor circuit is open or shorted.)

• Engine oil temperature sensor

P0198

EOT SEN/CIRC

(Engine oil temperature

sensor circuit high)

An excessively high voltage from the engine

oil temperature sensor is sent to ECM.

+

−

Voltage

(Approx.)

EOT sensor

Connector

Terminal

F48

1

Ground

5.0 V