Nissan Sentra. Manual - part 372

EC-184

< DTC/CIRCUIT DIAGNOSIS >

[MRA8DE]

P0078 EVT CONTROL SOLENOID VALVE

4. Also check harness for short to ground.

Is the inspection result normal?

YES

>> Perform the trouble diagnosis for power supply circuit.

NO

>> Repair or replace error-detected parts.

3.

CHECK EXHAUST VALVE TIMING CONTROL SOLENOID VALVE GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between EVT control solenoid valve harness connector and ECM harness connec-

tor.

4. Also check harness for short to ground and to power.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace error-detected parts.

4.

CHECK EXHAUST VALVE TIMING CONTROL SOLENOID VALVE

Check the exhaust valve timing control solenoid valve. Refer to

EC-181, "Component Inspection (IVT Control

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-39, "Intermittent Incident"

.

NO

>> Replace exhaust valve timing control solenoid valve. Refer to

EM-49, "Removal and Installation"

Component Inspection (EVT Control Solenoid Valve)

INFOID:0000000009758445

1.

CHECK EXHAUST VALVE TIMING CONTROL SOLENOID VALVE-1

1. Turn ignition switch OFF.

2. Disconnect exhaust valve timing control solenoid valve harness connector.

3. Check resistance between exhaust valve timing control solenoid valve terminals as per the following.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Replace exhaust valve timing control solenoid valve. Refer to

EM-49, "Removal and Installation"

2.

CHECK EXHAUST VALVE TIMING CONTROL SOLENOID VALVE-2

1. Remove exhaust valve timing control solenoid valve. Refer to

.

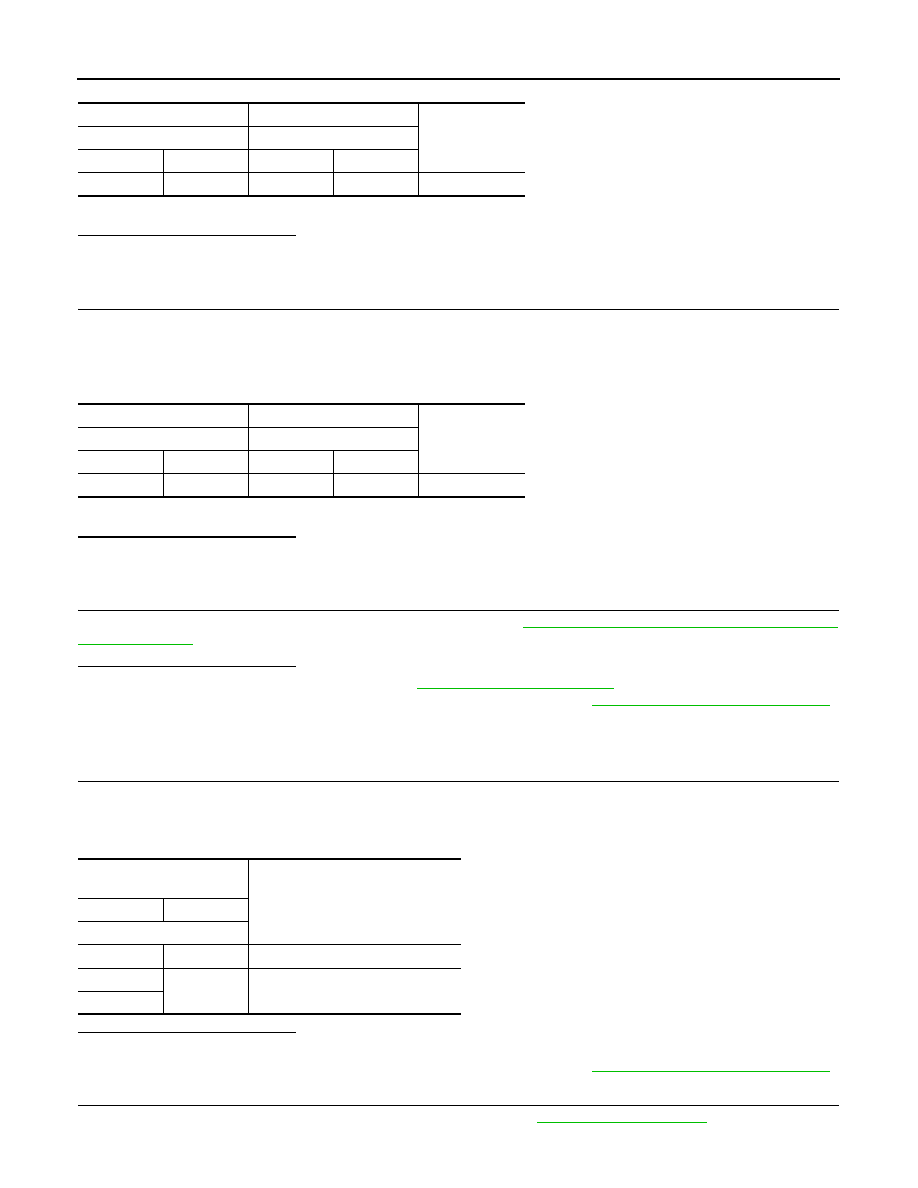

+

+

Continuity

EVT control solenoid valve

IPDM E/R

Connector

Terminal

Connector

Terminal

F55

1

E45

26

Existed

+

+

Continuity

EVT control solenoid valve

ECM

Connector

Terminal

Connector

Terminal

F55

2

F25

94

Existed

Exhaust valve timing control

solenoid valve

Resistance

+

−

Terminal

1

2

7.0 - 7.8

Ω [at 20°C (68°F)]

1

Ground

∞ Ω

(Continuity should not exist)

2