Nissan Sentra. Manual - part 170

C1113, C1145, C1146 YAW RATE/SIDE/DECEL G SENSOR

BRC-67

< DTC/CIRCUIT DIAGNOSIS >

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

N

O

P

C1113, C1145, C1146 YAW RATE/SIDE/DECEL G SENSOR

DTC Logic

INFOID:0000000009757844

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

CHECK SELF DIAGNOSTIC RESULT

With CONSULT.

1. Turn ignition switch OFF to ON.

2. Perform self diagnostic result.

Is DTC C1113, C1145 or C1146 detected?

YES

>> Proceed to diagnosis procedure. Refer to

.

NO

>> Inspection End.

Diagnosis Procedure

INFOID:0000000009757845

1.

REPLACE ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

Replace ABS actuator and electric unit (control unit).

>> Replace ABS actuator and electric unit (control unit). Refer to

BRC-110, "Removal and Installa-

.

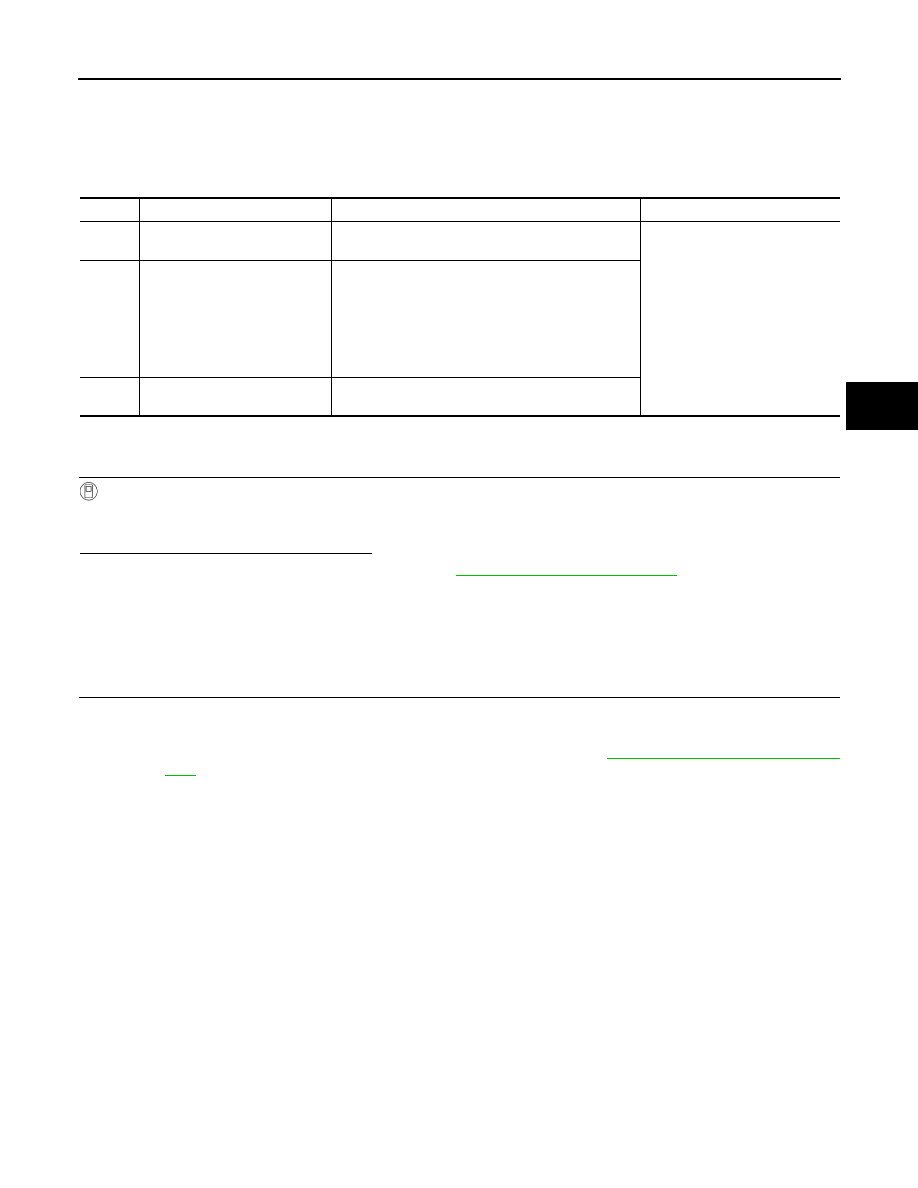

DTC

Display Item

Malfunction detected condition

Possible causes

C1113

G SENSOR

When a malfunction is detected in longitunal G sensor

signal.

• ABS actuator and electric unit

(control unit)

C1145

YAW RATE SENSOR

• When a malfunction is detected in yaw rate signal.

• When yaw rate signal is not continuously received

for 2 seconds or more.

• When side G signal is not continuously received for

2 seconds or more.

• When decel G signal is not continuously received

for 2 seconds or more.

C1146

SIDE G-SEN CIRCUIT

When a malfunction is detected in side/decel G sig-

nal.