Nissan Leaf. Manual - part 795

AUTOMATIC AIR CONDITIONING SYSTEM

HAC-183

< SYMPTOM DIAGNOSIS >

[AUTO A/C (WITH HEAT PUMP)]

C

D

E

F

G

H

J

K

L

M

A

B

HAC

N

O

P

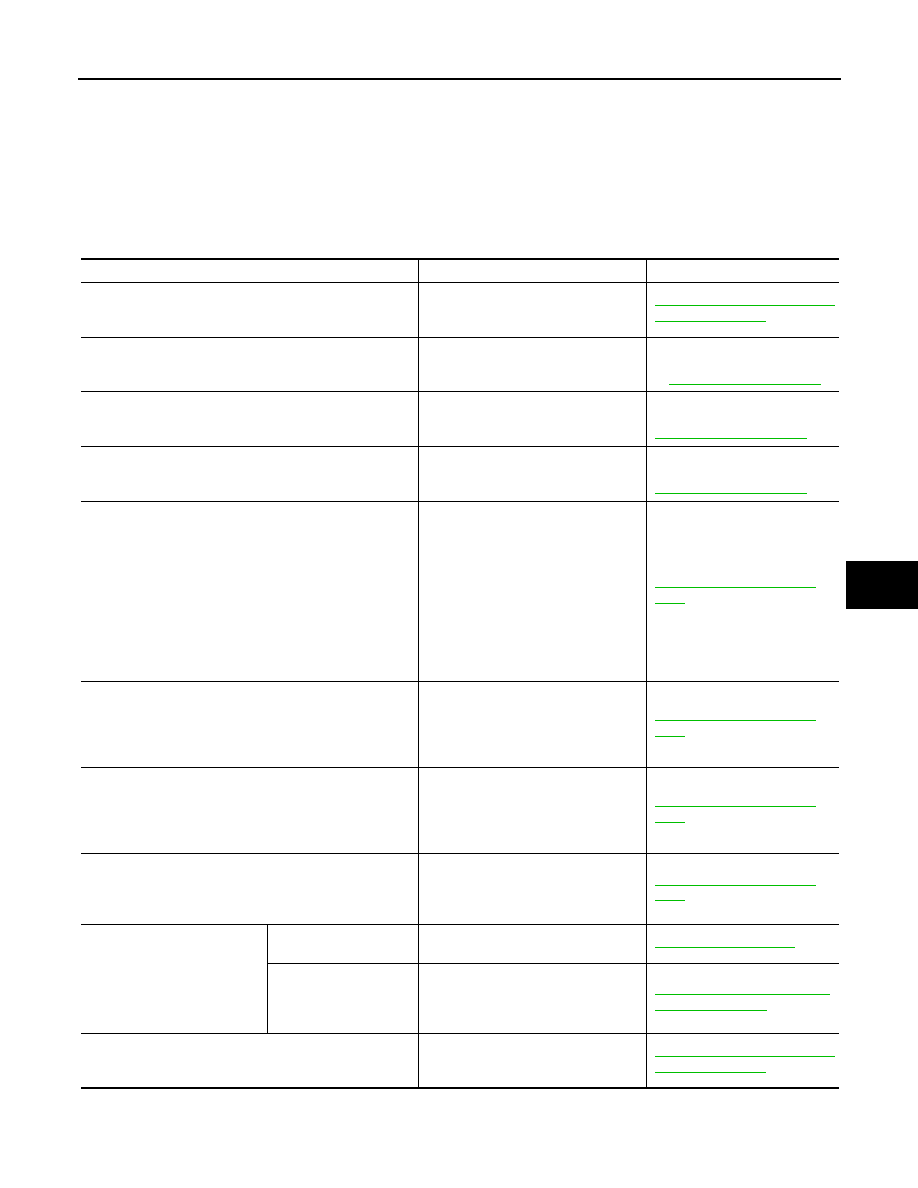

SYMPTOM DIAGNOSIS

AUTOMATIC AIR CONDITIONING SYSTEM

Symptom Table

INFOID:0000000010121885

NOTE:

Perform self-diagnoses with CONSULT before performing the symptom diagnosis. If any DTC is detected,

perform the corresponding diagnosis.

Symptom

Corresponding malfunctioning part

Check item/Reference

• Air conditioning system does not activate.

• Air conditioning system cannot be controlled.

• A/C auto amp. ignition power supply

and ground circuit

• A/C auto amp.

HAC-173, "A/C AUTO AMP. : Di-

agnosis Procedure"

Discharge air temperature does not change.

Air mix door motor system installation

condition

Check air mix door motor sys-

tem is properly installed. Refer

to

.

Air outlet does not change.

Mode door motor system installation

condition

Check mode door motor system

is properly installed. Refer to

.

Air inlet does not change.

Intake door motor system installation

condition

Check intake door motor system

is properly installed. Refer to

.

Blower motor does not operates or operation speed is not

normal.

• Blower motor power supply circuit

• Blower motor control circuit

• A/C auto amp. ignition power supply

circuit

• Power transistor power supply and

ground circuit

• Power transistor control signal cir-

cuit

• Blower motor

• Power transistor

• A/C auto amp.

HAC-175, "Diagnosis Proce-

dure"

Compressor does not operate.

• The circuit between VCM and refrig-

erant pressure sensor

• Refrigerant pressure sensor

• Blower fan ON signal circuit

• A/C auto amp.

HAC-186, "Diagnosis Proce-

dure"

• Insufficient cooling.

• No cool air comes out. (Air flow volume is normal.)

• Cooler cycle

• Air leakage from each duct

• A/C auto amp. connection recogni-

tion signal circuit

• Temperature setting trimmer

HAC-184, "Diagnosis Proce-

dure"

• Insufficient heating.

• No warm air comes out. (Air flow volume is normal.)

• Cooler cycle

• Air leakage from each duct

• Temperature setting trimmer

• A/C auto amp. connection

HAC-185, "Diagnosis Proce-

dure"

Noise is heard when the A/C

system operates.

During compressor op-

eration.

Cooler cycle

During blower motor op-

eration.

• Mixing any foreign object in blower

motor

• Blower motor fan breakage

• Blower motor rotation inferiority

HAC-177, "Component Inspec-

tion (Blower Motor)"

• Memory function does not operate normally.

• The setting is not maintained. (It returns to initial condi-

tion.)

• A/C auto amp. battery power supply

circuit

• A/C auto amp.