Nissan Leaf. Manual - part 743

HA-94

< SYMPTOM DIAGNOSIS >

[WITHOUT HEAT PUMP SYSTEM]

NOISE

NOISE

Symptom Table

INFOID:0000000010122168

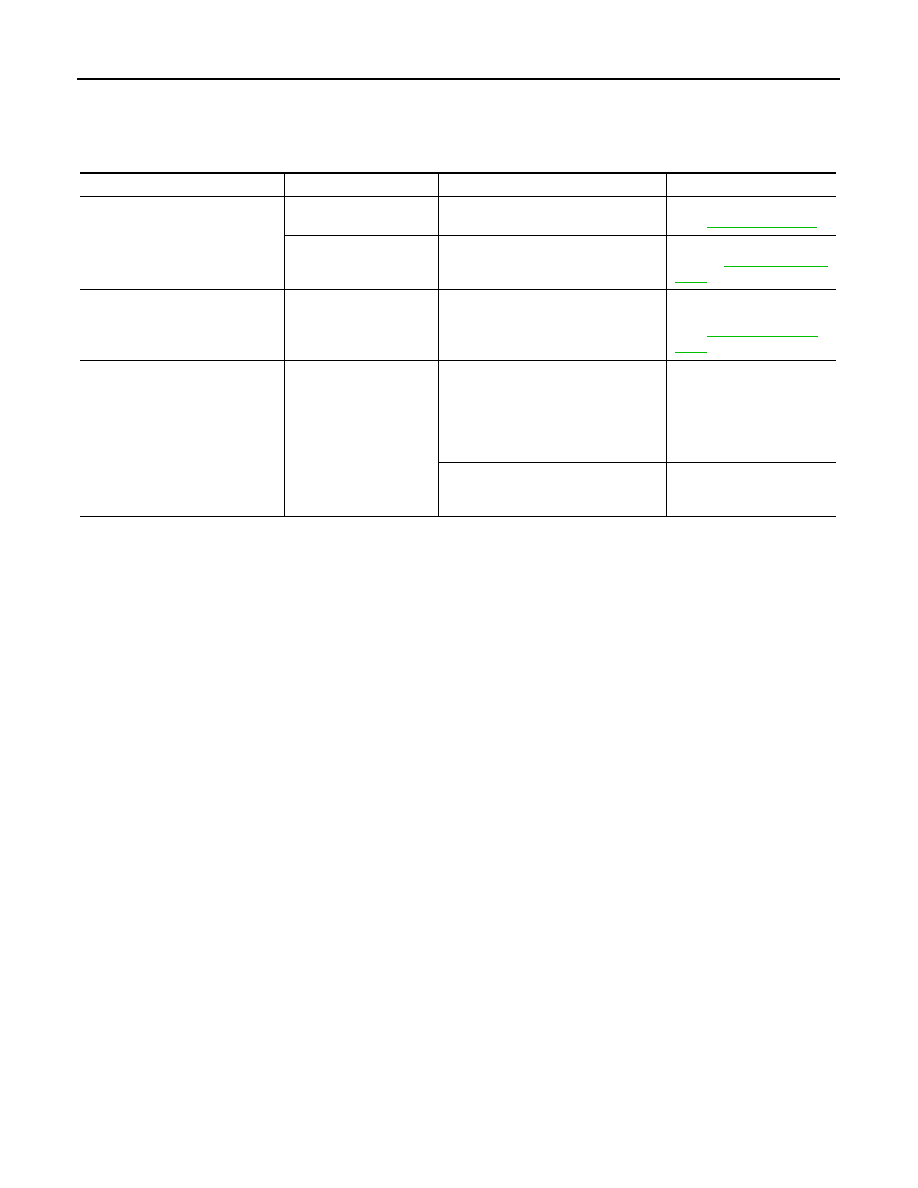

Symptom

Noise source

Probable cause

Corrective action

Unusual noise from compressor

when A/C is ON.

Inside of compressor

Wear, breakage, or clogging of foreign

material in inner parts.

Check compressor oil. Re-

fer to

.

Compressor body

Loosened compressor mounting bolts.

Check bolts for tightness.

Refer to

Unusual noise from cooler piping.

Cooler piping (pipe and

flexible hose)

Improper installation of clip and brack-

et.

Check the installation condi-

tion of the cooler piping. Re-

fer to

Unusual noise from expansion

valve when A/C is ON.

Expansion valve

Shortage of refrigerant.

• Check for leakage.

• Collect all refrigerant,

evacuate refrigerant cycle

again, and then refill it

with the specified amount

of refrigerant.

Wear, breakage, or clogging of foreign

material in inner parts.

Eliminate foreign material

from expansion valve, or re-

place it.