Nissan Leaf. Manual - part 726

HA-26

< BASIC INSPECTION >

[WITH HEAT PUMP SYSTEM]

REFRIGERANT

REFRIGERANT

Description

INFOID:0000000010122103

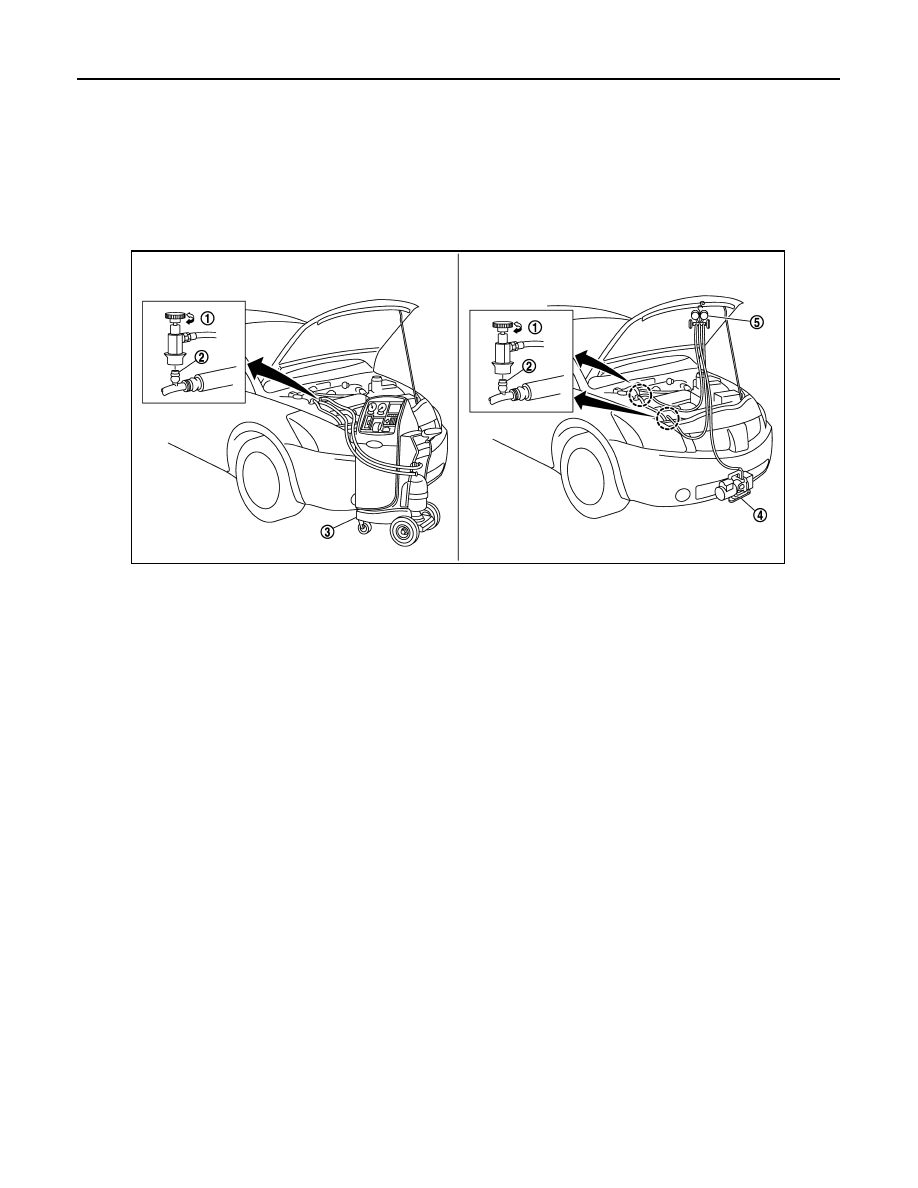

CONNECTION OF SERVICE TOOLS AND EQUIPMENT

CAUTION:

To prevent fluorescent indicator from entering, prepare and use exclusive hose for EV (electric vehi-

cle) and HEV (hybrid vehicle) when connecting recovery/recycling/recharging equipment.

Check Refrigerant Leakage

INFOID:0000000010122104

DETECTING LEAKAGES WITH FLUORESCENT INDICATOR

CAUTION:

Do not use fluorescent indicators as these may reduce the insulation resistance.

CHECK REFRIGERANT LEAKAGE USING ELECTRICAL LEAK DETECTOR

CAUTION:

Be careful of the following items so that inaccurate checks or misidentifications are avoided.

• Do not allow refrigerant vapor, shop chemical vapors, cigarette smoke, or others around the vehicle.

• Always check refrigerant leakage in a low air flow environment so that refrigerant may not disperse

when leakage occurs.

1. Connect recovery/recycling/recharging equipment (for HFC-134a) or manifold gauge set to A/C service

valve.

2. Check that refrigerant gas pressure is 345 kPa (3.5 kg/cm

2

, 50 psi) or more when temperature is 16

°C

(61

°F) or more. When pressure is lower than the specified value, fully recover all refrigerant and then

charge with refrigerant from the service can to the specified level.

NOTE:

Leakages may not be detected if refrigerant gas pressure is 345 kPa (3.5 kg/cm

2

, 50 psi) less when tem-

perature is 16

°C (61°F) or less.

3. Clean area where refrigerant leakage check is performed, and check refrigerant leakage along all sur-

faces of pipe connections and A/C system components using electrical leak detector probe.

CAUTION:

• Even when a leakage point has been found, always continue and complete checking along all

pipe connections and A/C system components for additional leakage.

• When a leakage is detected, clean leakage area using compressed air and check again.

1.

Shut-off valve

2.

A/C service valve

3.

Recovery/recycling/recharging

equipment (for HFC-134a)

4.

Vacuum pump

5.

Manifold gauge set

JPIIA0127ZZ