Nissan Leaf. Manual - part 724

HA-18

< SYSTEM DESCRIPTION >

[WITH HEAT PUMP SYSTEM]

COMPONENT PARTS

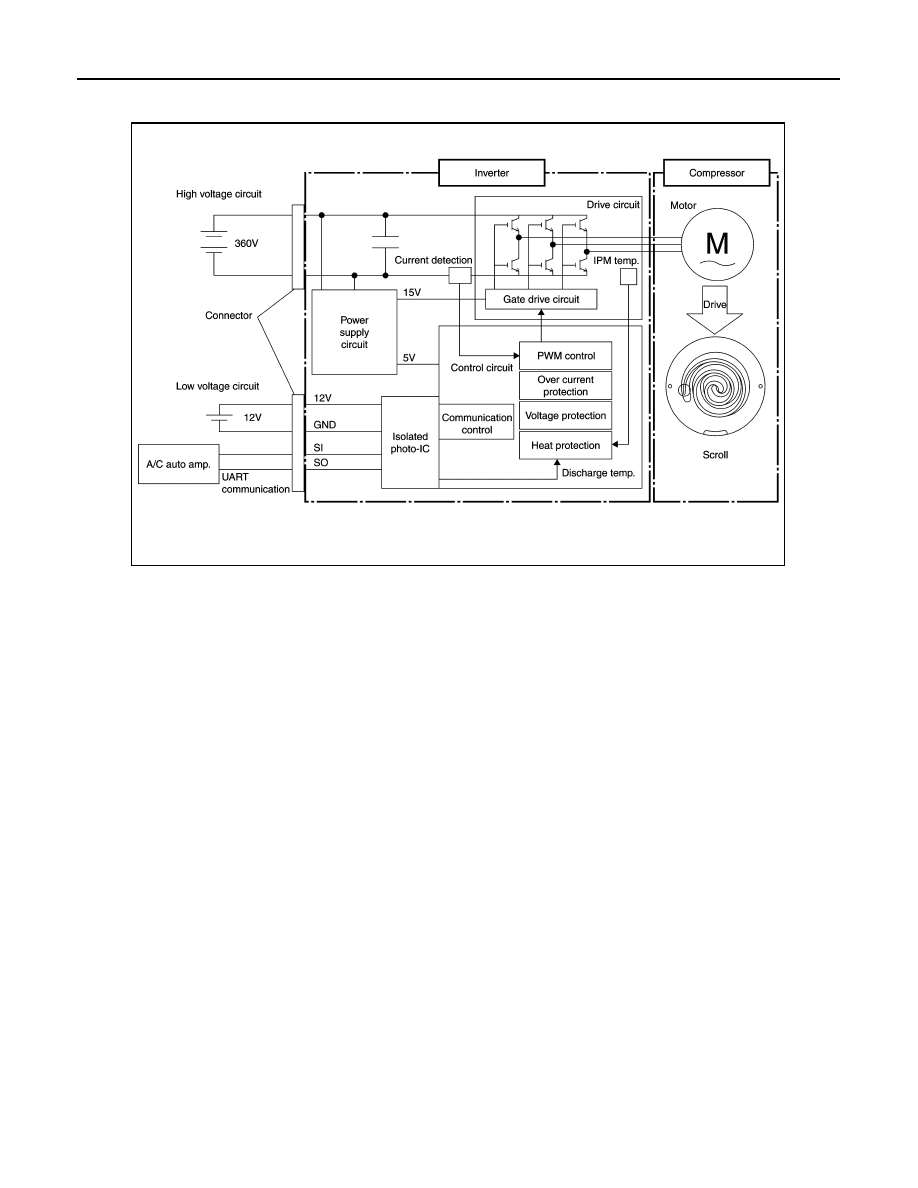

• The inverter communicates with A/C auto amp., and uses PWM control

Note

to control the motor speed via

the drive circuit.

NOTE:

• PWM (Pulse Width Modulation) is a system that controls current and voltage by changing the duty ratio of

a constant frequency pulse wave.

• PWM is used as the adjustment method of output voltage when inverter is used as a power supply for con-

trolling motor speed.

• PWM changes voltage application time (pulse width) using a semiconductor element and controls motor

speed.

• The IPM contains an internal protection circuit, and uses the inverter control circuit to monitor for an

increase in motor drive circuit temperature in order to prevent circuit overheating.

• The motor uses a DC brushless motor, with speed control performed by the inverter drive circuit.

JMIIA2059GB