Nissan Leaf. Manual - part 709

GI-48

< PRECAUTION >

PROCEDURE FOR PARK LOCK RELEASE

• METER 1

4. Release parking brake.

5. Turn power switch OFF. (Release brake pedal)

6. Move the vehicle while power switch is OFF.

7. Fix the vehicle after moving. (Using parking brake or tire stopper)

8. Install fuse that is removed.

9. Turn power switch ON (Press switch twice without depressing brake pedal) and wait for 5 seconds at this

moment, maintain the shift position to the N position. (Charge 12V battery if its voltage is low)

10. Turn power switch OFF. (Wait for 5 seconds)

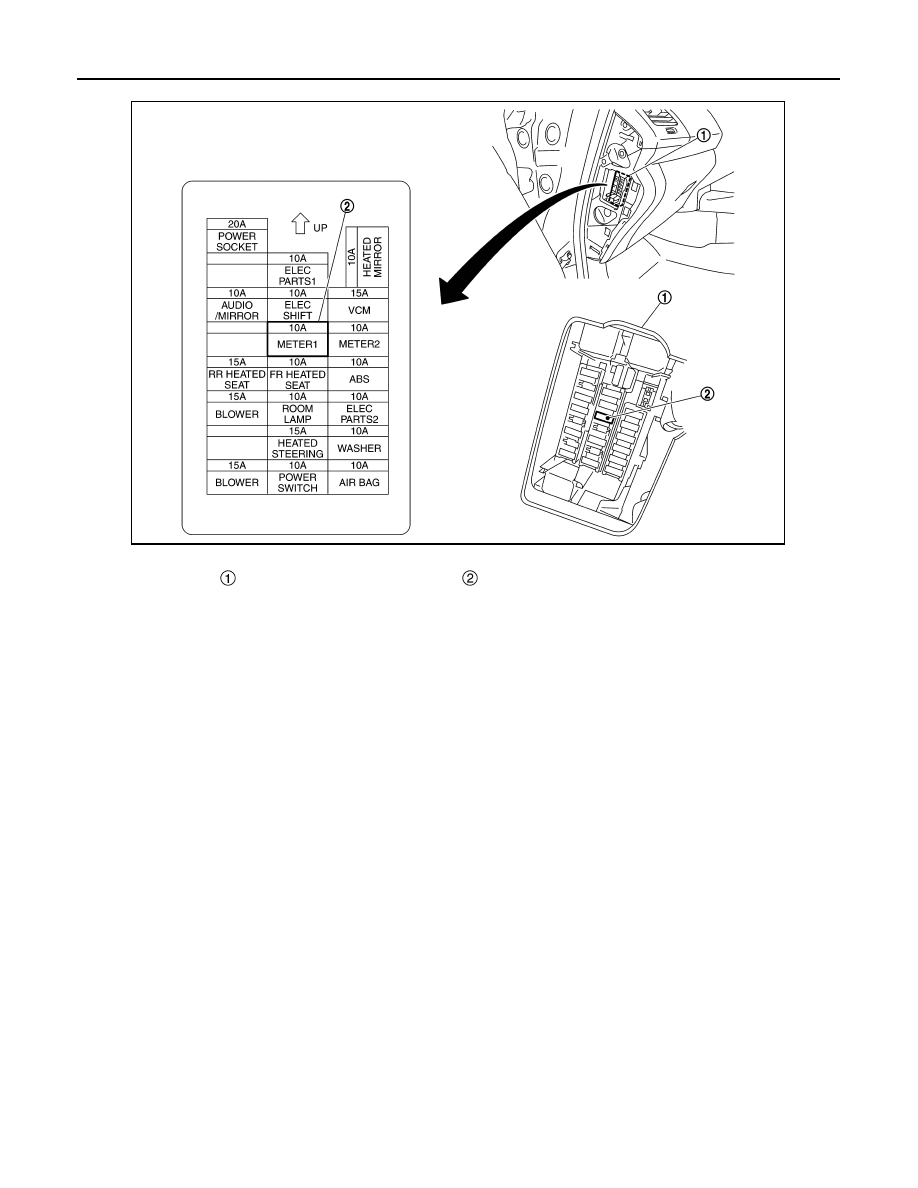

Fuse block

METER 1 fuse

JMAIA1125ZZ