Nissan Leaf. Manual - part 627

OPTICAL SENSOR

EXL-109

< DTC/CIRCUIT DIAGNOSIS >

[LED HEADLAMP]

C

D

E

F

G

H

I

J

K

M

A

B

EXL

N

O

P

OPTICAL SENSOR

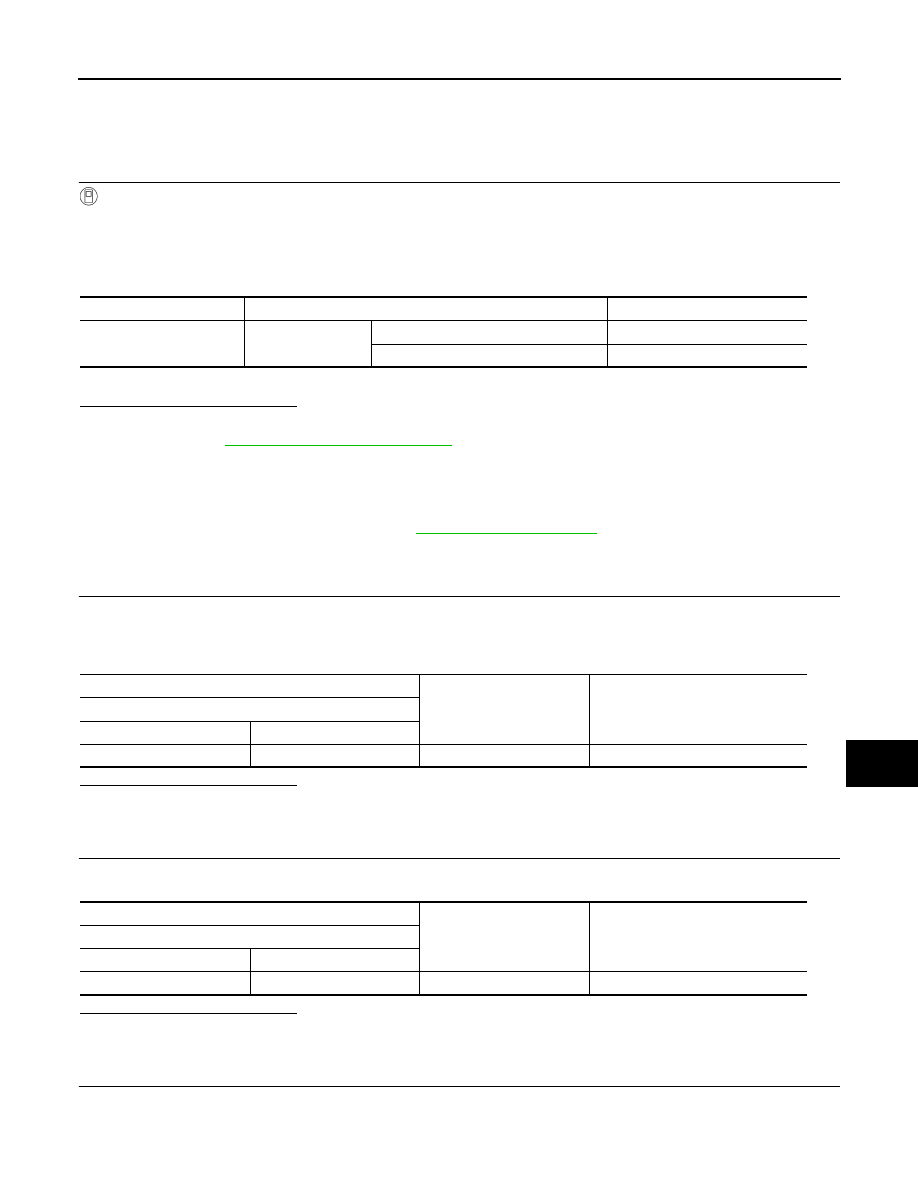

Component Function Check

INFOID:0000000010121365

1.

CHECK OPTICAL SENSOR SIGNAL BY CONSULT

CONSULT DATA MONITOR

1. Turn power switch ON.

2. Select “OPTISEN (DTCT)” in “Data Monitor” of “BCM (HEADLAMP)”.

3. Turn lighting switch AUTO.

4. With the optical sensor illuminating, check the monitor status.

*: Illuminates the optical sensor. The value may be less than the standard value if brightness is weak.

Is the inspection result normal?

YES

>> Optical sensor is normal.

NO

>> Refer to

EXL-109, "Diagnosis Procedure"

.

Diagnosis Procedure

INFOID:0000000010121366

Regarding Wiring Diagram information. Refer to

1.

CHECK OPTICAL SENSOR POWER SUPPLY INPUT

1. Turn power switch ON.

2. Turn lighting switch AUTO.

3. Check voltage between optical sensor harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> GO TO 4.

2.

CHECK OPTICAL SENSOR GROUND INPUT

Check voltage between optical sensor harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> GO TO 6.

3.

CHECK OPTICAL SENSOR SIGNAL OUTPUT

With illuminating the optical sensor, check voltage between optical sensor harness connector and ground.

Monitor item

Condition

Voltage (Approx.)

OPTISEN (DTCT)

Optical sensor

When illuminating

3.1 V or more *

When shutting off light

0.6 V or less

(+)

(

−)

Voltage

(Approx.)

Optical sensor

Connector

Terminal

M16

1

Ground

5 V

(+)

(

−)

Voltage

(Approx.)

Optical sensor

Connector

Terminal

M16

3

Ground

0 V