Nissan Leaf. Manual - part 530

EVC-144

< DTC/CIRCUIT DIAGNOSIS >

P0A00 COOLANT TEMPERATURE SENSOR

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> GO TO 5.

3.

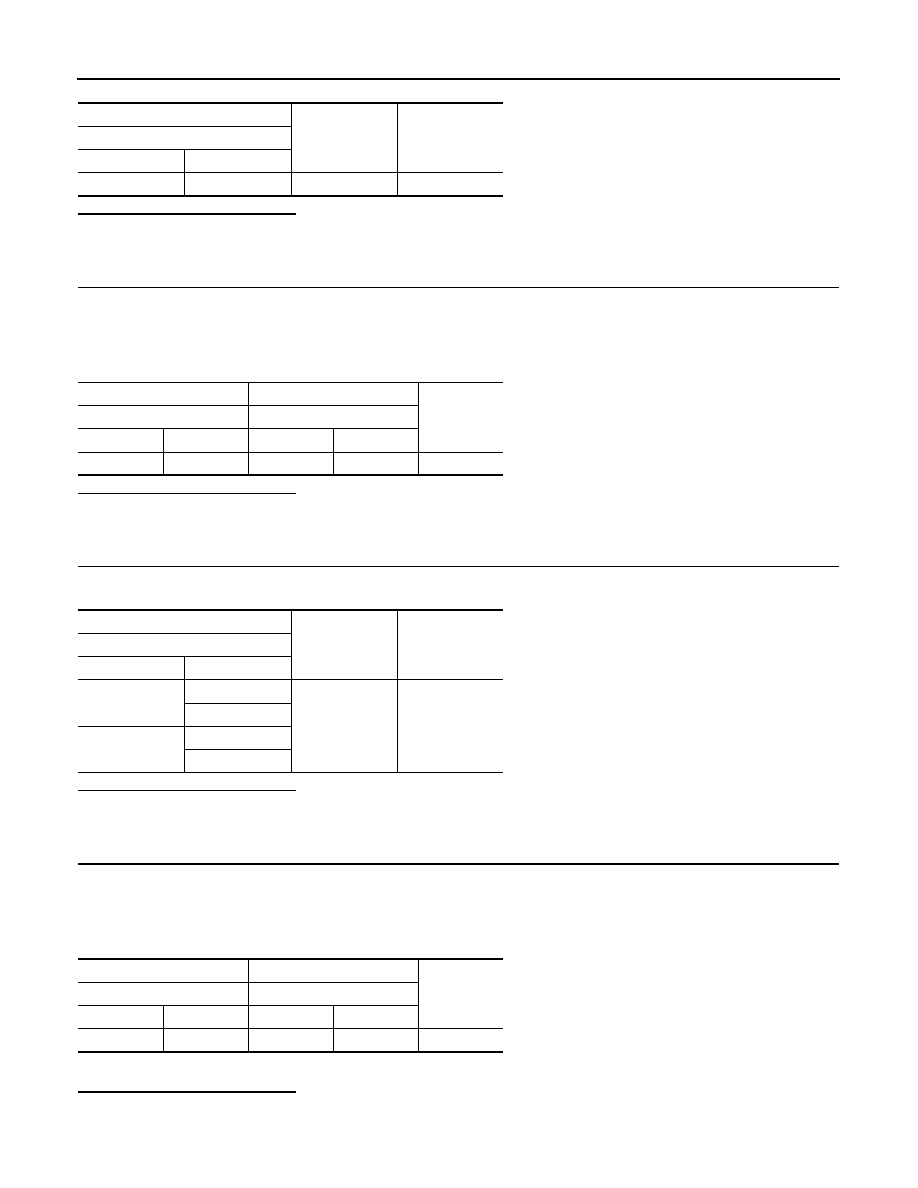

CHECK COOLANT TEMPERATURE SENSOR GROUND CIRCUIT

1. Turn power switch OFF.

2. Disconnect VCM harness connector.

3. Check the continuity between VCM harness connector and coolant temperature sensor harness connec-

tor.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace error-detected parts.

4.

CHECK VCM GROUND CIRCUIT

Check the continuity between VCM harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> Repair or replace error-detected parts.

5.

CHECK SENSOR POWER SUPPLY CIRCUIT

1. Turn power switch OFF.

2. Disconnect VCM harness connector.

3. Check the continuity between VCM harness connector and coolant temperature sensor harness connec-

tor.

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Repair or replace error-detected parts.

+

−

Voltage

(Approx.)

Coolant temperature sensor

Connector

Terminal

E69

1

Ground

5 V

+

−

Continuity

VCM

Coolant temperature sensor

Connector

Terminal

Connector

Terminal

E62

121

E69

2

Existed

+

−

Continuity

VCM

Connector

Terminal

E61

58

Ground

Existed

65

E63

118

126

+

−

Continuity

VCM

Coolant temperature sensor

Connector

Terminal

Connector

Terminal

E62

110

E69

1

Existed